Proper placement of a multi-zone tube furnace is a foundational step for ensuring operational accuracy, safety, and equipment longevity. The ideal location must have excellent air circulation, be free from vibration and dust, and contain no flammable or explosive materials. Crucially, you must confirm the power supply voltage is correct and that the equipment is effectively grounded before any operation.

The physical location of your furnace is only the first step. True success depends on a systematic approach that integrates environmental stability, precise mechanical assembly, and rigorous safety protocols from day one.

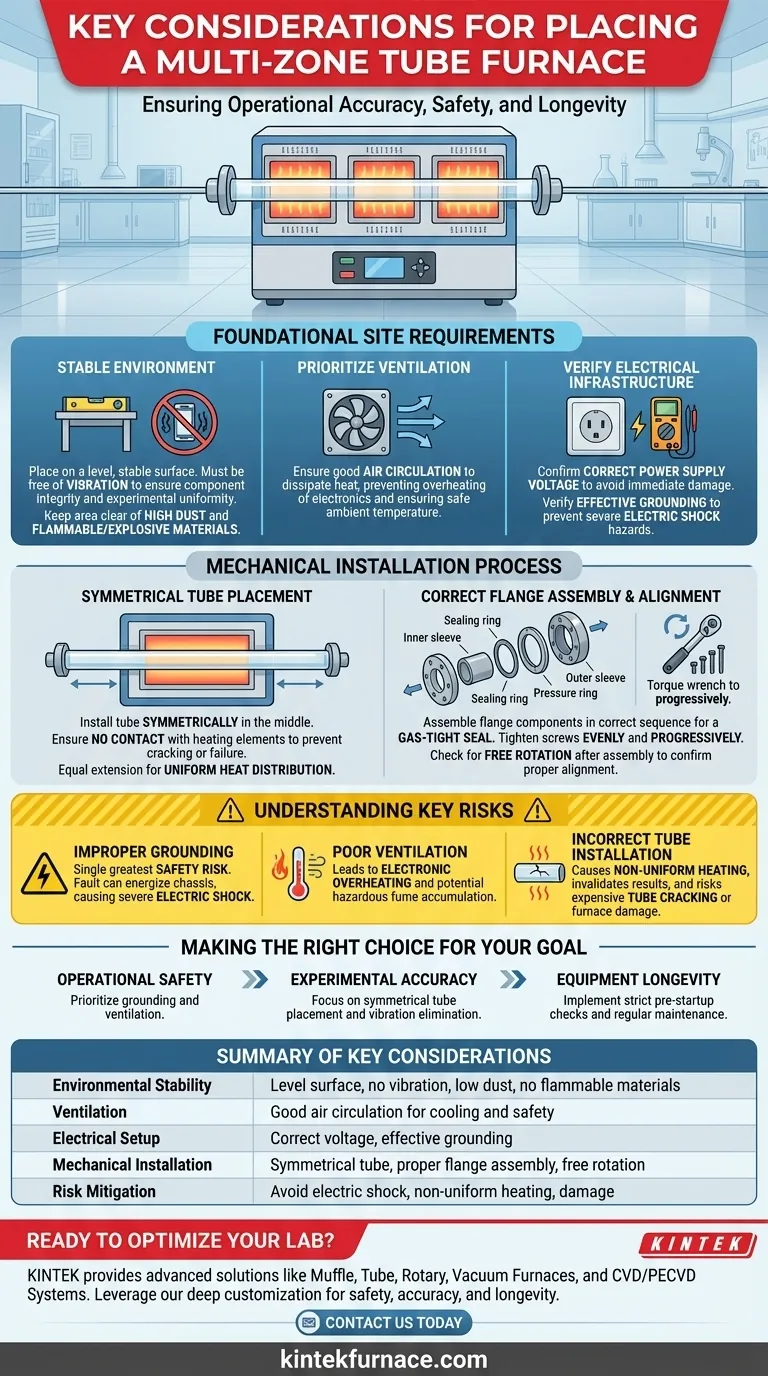

Foundational Site Requirements

Before the furnace is unboxed, the chosen site must be properly prepared. Overlooking these environmental and electrical prerequisites is a common source of operational failure and safety incidents.

Ensure a Stable Environment

The furnace must be placed on a level, stable surface where it will not be subjected to any vibration. Vibrations can compromise internal components and affect the uniformity of your experimental results.

The area must also be free of high dust levels and any flammable or explosive gases. Contaminants in the air can damage the equipment and create significant safety hazards when combined with high temperatures.

Prioritize Ventilation

Good air circulation is non-negotiable. The furnace generates significant heat, and proper ventilation is critical for dissipating it effectively to prevent the unit from overheating and to maintain a safe ambient temperature in the lab.

Verify Electrical Infrastructure

Before connection, confirm that your facility's power supply voltage matches the equipment's requirements. An incorrect voltage can instantly damage the furnace's electrical systems.

Most importantly, ensure the outlet provides effective grounding. Proper grounding is a critical safety feature that protects operators from the risk of severe electric shock. This should be verified by a qualified professional.

The Mechanical Installation Process

With the site prepared, the focus shifts to the precise mechanical assembly of the furnace components. Each step is designed to ensure uniform heating and a secure, leak-proof system.

Symmetrical Tube Placement

The furnace tube must be installed symmetrically, positioned exactly in the middle of the furnace chamber. It is critical that the tube does not touch the heating elements, as direct contact can cause the tube to crack or the elements to fail.

Adjust the tube so an equal length extends from both ends of the furnace. This balance helps ensure uniform heat distribution across your sample.

Correct Flange Assembly

A gas-tight seal is essential for atmosphere control. Install the flange components in the correct sequence: inner flange sleeve, sealing ring, pressure ring, and finally the outer flange sleeve.

Tighten the screws on the flange evenly and progressively to prevent the seal from skewing, which would result in a leak.

Final Alignment Checks

Once assembled, gently check that the furnace tube can rotate freely without binding. This confirms that it is not under stress and is properly aligned within the chamber.

Understanding the Key Risks

Avoiding common mistakes during installation is just as important as following the correct procedures. Understanding the consequences of these errors underscores their importance.

The Risk of Improper Grounding

Failure to ensure effective grounding is the single greatest safety risk. Without it, a fault in the electrical system could energize the furnace's chassis, creating a severe electric shock hazard for any operator who touches it.

The Impact of Poor Ventilation

Inadequate air circulation can lead to two primary problems. First, the furnace's electronic components can overheat, leading to premature failure and costly repairs. Second, if you are working with hazardous materials, fumes can accumulate in the workspace instead of being safely exhausted.

Consequences of Incorrect Tube Installation

If a furnace tube is installed asymmetrically or touches the heating elements, you will get non-uniform heating, invalidating your experimental results. Worse, the thermal stress can cause an expensive quartz or alumina tube to crack, ruining an experiment and potentially damaging the furnace itself.

Making the Right Choice for Your Goal

Your specific experimental needs will determine which aspects of the installation process demand the most attention.

- If your primary focus is operational safety: Prioritize effective grounding and maintaining a well-ventilated, clutter-free zone above all else.

- If your primary focus is experimental accuracy: Concentrate on meticulous, symmetrical tube placement and eliminating all sources of environmental vibration.

- If your primary focus is equipment longevity: Implement a strict routine of pre-startup electrical checks and regular maintenance inspections of all circuits and heating elements.

A methodical approach to placement and installation transforms your furnace from a piece of equipment into a reliable and safe scientific instrument.

Summary Table:

| Consideration | Key Points |

|---|---|

| Environmental Stability | Level surface, no vibration, low dust, no flammable materials |

| Ventilation | Good air circulation to prevent overheating and ensure safety |

| Electrical Setup | Correct voltage, effective grounding verified by a professional |

| Mechanical Installation | Symmetrical tube placement, proper flange assembly, free rotation |

| Risk Mitigation | Avoid electric shock, non-uniform heating, and equipment damage |

Ready to optimize your lab with a reliable high-temperature furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for enhanced safety, accuracy, and longevity. Contact us today to discuss how we can support your specific needs!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control