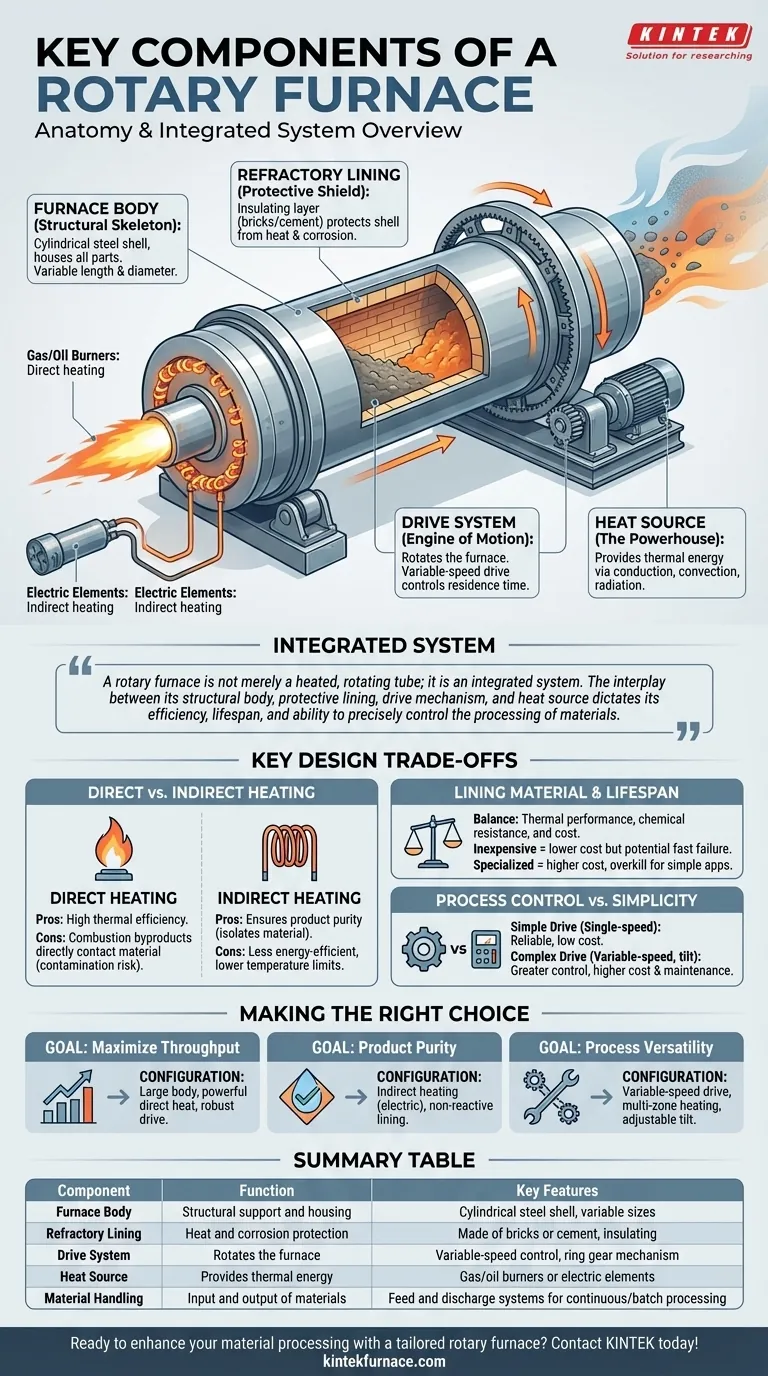

At its core, a rotary furnace is built from four fundamental components. These are the furnace body which provides the structure, an internal refractory lining to contain heat and resist corrosion, a drive system to create rotation, and a heat source to provide the necessary thermal energy.

A rotary furnace is not merely a heated, rotating tube; it is an integrated system. The interplay between its structural body, protective lining, drive mechanism, and heat source dictates its efficiency, lifespan, and ability to precisely control the processing of materials.

The Anatomy of a Rotary Furnace: A Component-by-Component Breakdown

To truly understand how a rotary furnace operates, we must examine each of its core parts and the specific function it performs within the larger system.

The Furnace Body: The Structural Skeleton

The furnace body is the cylindrical shell, typically constructed from welded steel plates. It is the primary structural component that houses all other parts.

The length and diameter of this body are highly variable, ranging from small laboratory models to massive industrial kilns that can be over 200 meters long, depending entirely on the required throughput and process.

The Refractory Lining: The Protective Shield

Inside the steel body is the refractory lining. This layer is crucial for protecting the steel shell from the extreme internal temperatures and from chemical or abrasive wear from the material being processed.

This lining is made from heat-resistant materials like refractory bricks, castable refractory cement, or other moldable substances chosen for their specific insulating and corrosion-resistant properties.

The Drive System: The Engine of Motion

The drive system is the mechanism that rotates the furnace body. This is typically accomplished with a large ring gear fixed to the shell, which is turned by a motor-driven pinion.

A key feature is the use of a variable-speed drive. This allows operators to precisely control the rotation speed, which in turn controls how long the material remains in the furnace (its residence time), a critical process parameter. Some systems also allow for adjusting the tilt to influence material flow.

The Heat Source: The Powerhouse

The heat source provides the thermal energy required for the process. This can be accomplished in several ways.

Common sources include gas or oil burners that fire directly into the furnace chamber or electric heating elements positioned around the furnace tube for indirect heating. Heat is transferred to the material through a combination of conduction, convection, and radiation, enhanced by the tumbling action from the rotation.

Material Handling Systems: The Input and Output

While part of the larger process, the feed and discharge systems are integral to the furnace's operation. These mechanisms are responsible for continuously or batch-feeding raw materials into one end of the furnace and removing the processed product from the other.

Understanding the Key Design Trade-offs

The choice and configuration of these components involve critical trade-offs that impact performance, cost, and suitability for a given application.

Direct vs. Indirect Heating

A furnace with an internal gas burner (direct heating) offers very high thermal efficiency. However, the byproducts of combustion come into direct contact with the process material, which can be a source of contamination.

Using external electric heating elements (indirect heating) ensures product purity by isolating the material from the heat source. This method, however, is often less energy-efficient and may have upper temperature limitations compared to direct-fired systems.

Lining Material and Lifespan

The selection of refractory material is a balance between thermal performance, chemical resistance, and cost. An inexpensive lining may reduce initial capital cost but fail quickly if used with highly corrosive materials, leading to costly downtime and repairs. A specialized, expensive lining is necessary for harsh chemical environments but would be overkill for simpler applications.

Process Control vs. Simplicity

A basic, single-speed drive system is simple and reliable. However, a more complex system with variable-speed rotation, multi-zone temperature control, and tilt adjustment provides far greater control over the final product characteristics. This added complexity comes with a higher initial cost and increased maintenance requirements.

Making the Right Choice for Your Goal

The optimal configuration of a rotary furnace depends entirely on your primary objective.

- If your primary focus is maximizing throughput: You will need a large-diameter, long furnace body with a powerful, direct-fired heat source and a robust drive system.

- If your primary focus is product purity: An indirectly heated furnace (typically electric) with a carefully selected, non-reactive refractory lining is the correct choice.

- If your primary focus is process versatility: Prioritize a system with a variable-speed drive, multi-zone heating controls, and an adjustable tilt mechanism to handle a wide range of materials and specifications.

Understanding how each component contributes to the whole empowers you to specify a system perfectly tailored to your unique processing needs.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Body | Structural support and housing | Cylindrical steel shell, variable sizes |

| Refractory Lining | Heat and corrosion protection | Made of bricks or cement, insulating |

| Drive System | Rotates the furnace | Variable-speed control, ring gear mechanism |

| Heat Source | Provides thermal energy | Gas/oil burners or electric elements |

| Material Handling | Input and output of materials | Feed and discharge systems for continuous/batch processing |

Ready to enhance your material processing with a tailored rotary furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your lab's efficiency and performance!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput