In short, an induction gold melting furnace offers significant advantages in speed, purity, control, and efficiency over traditional methods like gas or resistance furnaces. It melts gold in minutes, prevents contamination through a non-contact process, and uses electromagnetic stirring to create a perfectly homogenous alloy, all while consuming less energy.

The fundamental advantage of induction is not just one feature, but a paradigm shift in the heating process itself. Instead of heating the crucible, induction uses an electromagnetic field to generate heat directly within the gold, giving you unprecedented control over the melt.

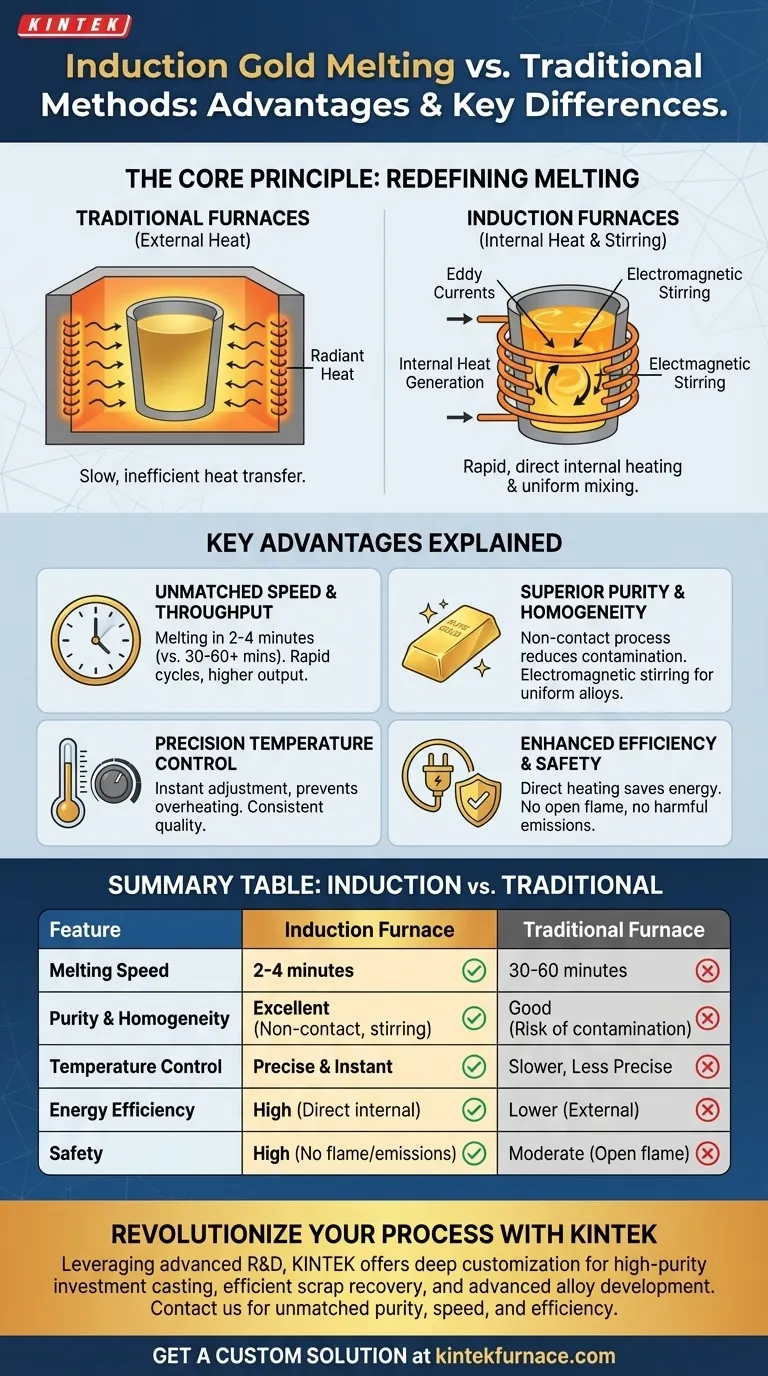

The Core Principle: How Induction Redefines Melting

To understand the benefits, you must first understand the core difference in technology. Traditional furnaces are like conventional ovens; they heat an element, which then radiates heat to the crucible and, finally, to the metal.

The Power of Internal Heat Generation

Induction heating works more like a microwave oven. An alternating magnetic field induces electrical currents (known as eddy currents) directly inside the gold itself.

The metal's natural electrical resistance causes it to heat up rapidly from within. This eliminates the slow, inefficient transfer of heat from an external source.

The Advantage of Electromagnetic Stirring

This same magnetic field also creates a stirring effect throughout the molten metal. This is a critical, built-in feature that cannot be easily replicated in traditional furnaces.

This constant, gentle stirring ensures all metals in an alloy, such as copper or silver, are distributed perfectly evenly. The result is a highly homogenous final product, free from inconsistencies.

Key Advantages Explained

The shift to internal heating produces a cascade of benefits that impact quality, speed, and operational cost.

Unmatched Speed and Throughput

Because heat is generated instantly within the gold, melting times are drastically reduced. A process that might take an hour in a traditional furnace can be completed in just 2 to 4 minutes with induction.

This rapid cycle time directly translates to higher production output and greater operational agility.

Superior Purity and Homogeneity

Induction is a non-contact heating process. The heating coil never touches the crucible or the metal, which dramatically reduces the risk of contamination from heating elements.

When operated under a vacuum or in an inert gas atmosphere, induction melting can produce materials of exceptionally high purity, which is critical for investment casting and advanced applications.

Precision Temperature and Atmosphere Control

Induction systems allow for exact, repeatable temperature control. The power can be adjusted instantly, preventing the overheating that can cause metal loss or damage to the crucible.

This precise control, combined with the electromagnetic stirring, ensures every batch has a uniform temperature and composition, leading to consistent, high-quality results.

Enhanced Energy Efficiency and Safety

By heating only the metal, induction furnaces waste very little energy heating the surrounding air or equipment. This direct heating method is significantly more energy-efficient than traditional furnaces, lowering long-term operating costs.

Furthermore, since there is no open flame or combustible fuel, the process is inherently safer and produces no harmful emissions, creating a cleaner working environment.

Understanding the Trade-offs

No technology is without its considerations. Objectivity requires acknowledging where traditional methods may still have a place.

Initial Capital Investment

Induction furnaces typically require a higher upfront investment compared to simple gas or resistance furnaces. The technology, including the power supply and water-cooling system, is more complex.

Operational Complexity

While modern systems are highly automated, they are more sophisticated than a basic furnace. Operators may require specific training, and maintenance involves electronics and cooling systems, not just simple refractory or element replacement.

Scale and Application

For very large-scale, low-purity melting operations (like initial scrap recovery), a massive traditional furnace might offer a lower cost per ton. Induction excels in applications where quality, speed, and precision are the dominant factors.

Making the Right Choice for Your Goal

The best technology depends entirely on your operational priorities.

- If your primary focus is maximum purity and alloy consistency: Induction is the definitive choice due to its non-contact heating and electromagnetic stirring.

- If your primary focus is high throughput and energy efficiency: The rapid melting cycles and lower energy consumption of induction offer a clear long-term advantage.

- If your primary focus is minimizing upfront cost for low-volume or non-critical melts: A traditional gas or resistance furnace may still serve as a functional entry point.

Ultimately, adopting induction melting is a strategic decision to prioritize control, quality, and efficiency in your process.

Summary Table:

| Advantage | Induction Furnace | Traditional Furnace |

|---|---|---|

| Melting Speed | 2-4 minutes | 30-60 minutes |

| Purity & Homogeneity | Excellent (Non-contact, electromagnetic stirring) | Good (Risk of contamination, limited stirring) |

| Temperature Control | Precise and instant | Slower, less precise |

| Energy Efficiency | High (Direct internal heating) | Lower (External heating) |

| Safety | High (No open flame, no emissions) | Moderate (Open flame, potential emissions) |

Ready to Revolutionize Your Gold Melting Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides jewelers, refiners, and research labs with advanced induction melting solutions. Our product line, including Muffle, Tube, Rotary, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique melting requirements—whether for high-purity investment casting, efficient scrap recovery, or advanced alloy development.

Contact us today to discuss how our induction furnaces can deliver unmatched purity, speed, and efficiency for your operation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity