At its core, a horizontal electric furnace offers a superior combination of precise environmental control and operational accessibility. Its primary advantages lie in providing highly uniform heat distribution along a sample's length, enabling strict control over the internal atmosphere (including vacuum), and allowing for easy placement and observation of materials during processing.

The decision to use a horizontal furnace is not just about heating a sample; it's about controlling the entire thermal and atmospheric environment around it. Its key advantage is optimizing for process visibility and control, especially for stationary, elongated samples.

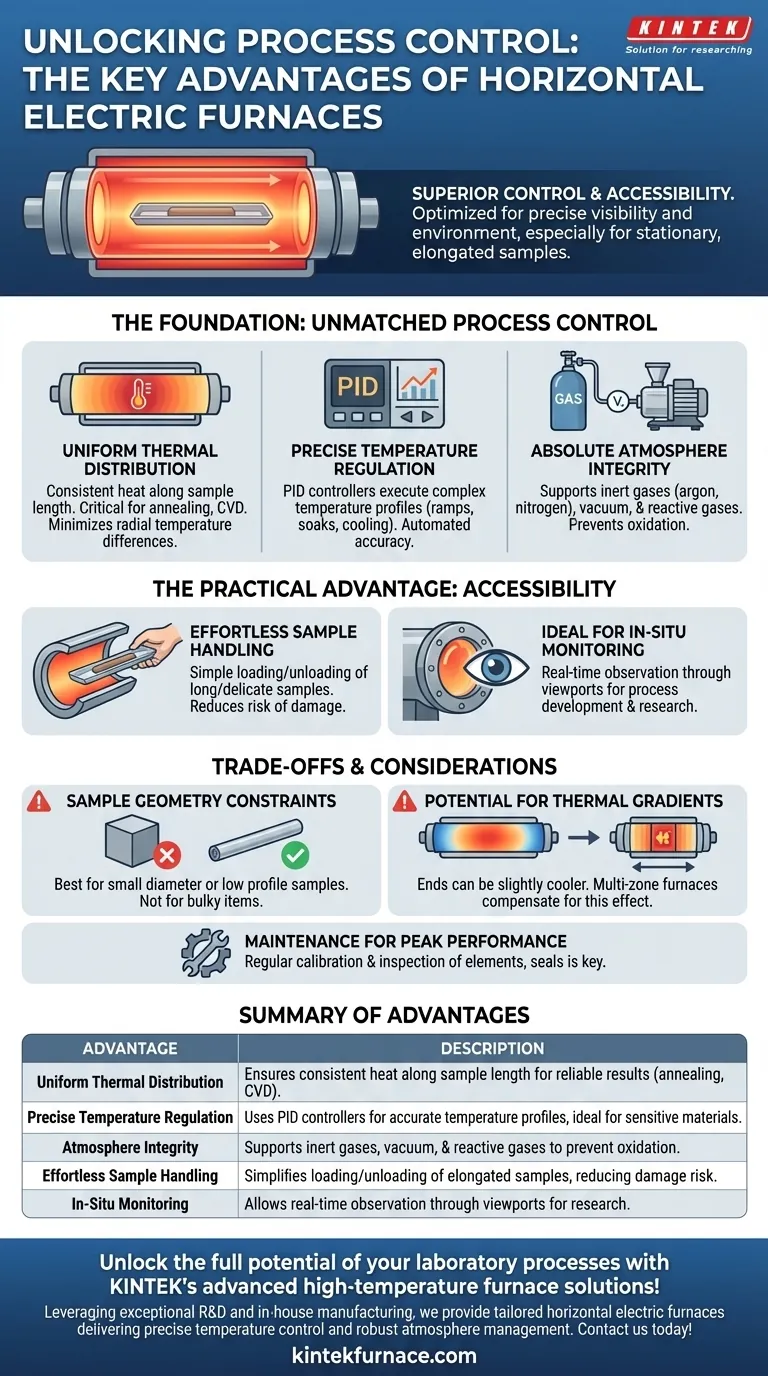

The Foundation: Unmatched Process Control

The defining strengths of a horizontal electric furnace are rooted in its ability to create a highly stable and repeatable processing environment. This is achieved through three key factors.

Uniform Thermal Distribution

The cylindrical or tube-like heating chamber of a horizontal furnace is ideal for delivering consistent, uniform heat along the entire length of a sample. This is critical for processes like annealing, crystallization, or chemical vapor deposition, where temperature consistency directly impacts the quality and reliability of the final result.

This design minimizes radial temperature differences, ensuring the sample is heated evenly from all sides.

Precise Temperature Regulation

Electric heating elements, combined with modern PID (Proportional-Integral-Derivative) controllers, allow for exceptionally precise temperature control. These systems can execute complex temperature profiles, including rapid heating ramps, extended soaking periods at a specific temperature, and controlled cooling cycles.

This level of automation and accuracy is far superior to traditional combustion-based methods and is essential for sensitive materials research and high-tech manufacturing.

Absolute Atmosphere Integrity

Many advanced materials are sensitive to oxidation at high temperatures. Horizontal tube furnaces excel at atmosphere control, easily accommodating inert gases like argon or nitrogen to create a protective environment.

Furthermore, they can be sealed to hold a vacuum, which is the ultimate protection against oxidation and is required for specific material purification processes. They can also be used with reducing or other reactive gases for specialized applications.

The Practical Advantage: Accessibility

Beyond environmental control, the physical orientation of a horizontal furnace provides distinct operational benefits that are crucial in both laboratory and production settings.

Effortless Sample Handling

The horizontal layout allows for simple loading and unloading of samples, which are typically held in a ceramic boat or tube. This is especially advantageous for long or delicate samples that would be difficult to manage in a top-loading vertical furnace.

This ease of access simplifies operation and reduces the risk of damaging the sample or the furnace interior.

Ideal for In-Situ Monitoring

This configuration is uniquely suited for experiments that require observation or manipulation during the heating process. The ends of the furnace tube can be fitted with viewports, allowing researchers to monitor physical changes like melting or color shifts in real-time.

This direct line of sight is invaluable for process development and fundamental scientific research.

Understanding the Trade-offs and Considerations

While highly effective, the horizontal design is not universally optimal. Understanding its limitations is key to making an informed decision.

Sample Geometry Constraints

Horizontal furnaces are best suited for samples with a relatively small diameter or low profile that can fit within a process tube. They are not efficient for heating large, bulky, or irregularly shaped objects, where a box furnace would be a better choice.

Similarly, they are not ideal for processing bulk powders or granules that require mixing to achieve thermal uniformity, a task better suited for a rotary furnace.

Potential for Thermal Gradients

While highly uniform, the ends of a single-zone furnace tube can be slightly cooler than the center. For applications requiring absolute temperature uniformity over a very long length, a multi-zone furnace with independent controllers for each section is necessary to compensate for this effect.

Maintenance for Peak Performance

The advantages of a horizontal furnace depend on proper upkeep. This includes regular calibration of temperature sensors, periodic inspection and replacement of heating elements, and ensuring the integrity of seals and gaskets to maintain atmosphere and vacuum capabilities.

Making the Right Choice for Your Application

Selecting the correct furnace requires matching its strengths to your primary process goal.

- If your primary focus is processing stationary, elongated samples or thin films: A horizontal tube furnace offers the best combination of uniform heating, atmosphere control, and direct observation.

- If your primary focus is batch processing powders or granules that require tumbling: A rotary furnace is superior for ensuring every particle is heated evenly through constant mixing.

- If your primary focus is heating larger, self-standing, or irregularly shaped parts: A box (or chamber) furnace provides the necessary volumetric space and simpler loading for bulkier items.

Ultimately, selecting a horizontal furnace is a strategic decision for any process where precise, observable control over a sample's linear environment is the most critical factor for success.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Thermal Distribution | Ensures consistent heat along sample length for reliable results in processes like annealing and CVD. |

| Precise Temperature Regulation | Uses PID controllers for accurate temperature profiles, ideal for sensitive materials research. |

| Atmosphere Integrity | Supports inert gases, vacuum, and reactive gases to prevent oxidation and enable specialized applications. |

| Effortless Sample Handling | Horizontal layout simplifies loading/unloading of elongated or delicate samples, reducing damage risk. |

| In-Situ Monitoring | Allows real-time observation through viewports for process development and scientific research. |

Unlock the full potential of your laboratory processes with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored horizontal electric furnaces that deliver precise temperature control, uniform heating, and robust atmosphere management. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs—ensuring optimal performance for applications like material annealing and chemical vapor deposition.

Ready to enhance your efficiency and results? Contact us today to discuss how our solutions can benefit your specific requirements!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab