At their core, vacuum furnaces provide significant environmental benefits by eliminating direct process emissions and maximizing energy efficiency. Unlike traditional atmosphere furnaces that burn fuel and consume process gases, a vacuum furnace uses electricity within a sealed, insulated chamber, which fundamentally changes its environmental footprint by preventing the creation of waste gas, wastewater, and other pollutants.

The environmental advantages of a vacuum furnace are not an add-on feature; they are a direct result of its fundamental design. By replacing combustion and flowing gas atmospheres with a sealed, electrically heated vacuum, the process inherently becomes cleaner, more contained, and more energy-efficient.

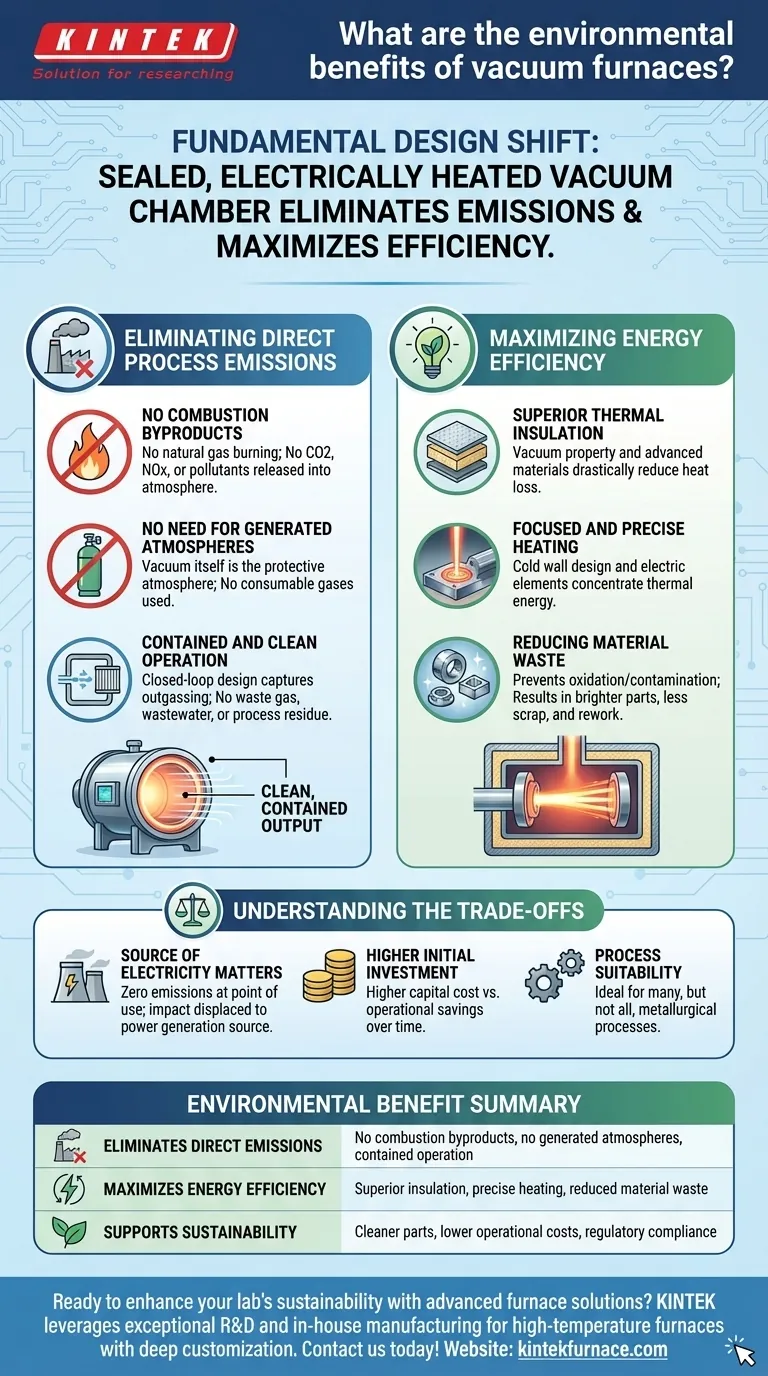

Eliminating Direct Process Emissions

The most immediate environmental benefit of vacuum technology is the near-total elimination of pollutants at the point of use. This is achieved by removing the two primary sources of emissions found in conventional furnaces: fuel combustion and protective atmospheres.

No Combustion Byproducts

Traditional furnaces often burn natural gas or other fossil fuels for heat, releasing carbon dioxide (CO2), nitrogen oxides (NOx), and other combustion byproducts directly into the atmosphere. Vacuum furnaces, in contrast, are typically heated electrically, shifting the emissions impact from your facility to the power grid.

No Need for Generated Atmospheres

Many heat-treating processes require a protective atmosphere to prevent the metal part from oxidizing. These atmospheres (e.g., endothermic gas) are often generated by combusting hydrocarbons, which consumes fuel and creates its own stream of emissions. In a vacuum furnace, the vacuum itself is the protective atmosphere, eliminating the need for these consumable gases and their associated emissions.

Contained and Clean Operation

Because the process occurs in a sealed chamber, any substances that "outgas" from the metal parts during heating are captured by the vacuum pump system. This prevents their release into the workplace or the environment. This closed-loop design means there is no waste gas, wastewater, or process residue to treat or dispose of.

Maximizing Energy Efficiency

Vacuum furnaces are engineered to use energy with exceptional efficiency. This reduces overall energy consumption, which lowers both operational costs and the indirect environmental impact associated with electricity generation.

Superior Thermal Insulation

A vacuum is one of the most effective insulators known. This inherent property, combined with advanced insulation materials inside the furnace's "hot zone," drastically reduces heat loss to the surrounding environment.

Focused and Precise Heating

The system's "cold wall" design, where the outer vessel is water-cooled, ensures that thermal energy is concentrated on the workload, not wasted heating the furnace structure or the factory floor. Electric heating elements also allow for extremely precise temperature control, avoiding the energy waste of overshooting and correcting temperature setpoints.

Reducing Material Waste

The clean vacuum environment prevents oxidation, decarburization, and other forms of surface contamination. This results in brighter, cleaner parts that often require no subsequent cleaning, grinding, or rework, saving energy and reducing the scrap rate from failed or rejected components.

Understanding the Trade-offs

No technology is a universal solution. An objective assessment requires acknowledging the associated trade-offs and considerations.

The Source of Electricity Matters

The "zero emissions" benefit is specific to the point of use. The overall environmental impact is displaced to the power plant generating the electricity. Therefore, the true carbon footprint of a vacuum furnace is directly tied to how cleanly your regional power grid operates.

Higher Initial Investment

Vacuum furnaces are sophisticated systems that typically carry a higher initial capital cost compared to conventional atmosphere furnaces. This investment must be weighed against long-term operational savings from reduced energy and consumable gas consumption.

Process Suitability

While highly versatile, vacuum furnaces are not the ideal choice for every metallurgical process. Certain surface treatments, like traditional gas carburizing, are intrinsically linked to carbon-rich atmospheres, though specialized vacuum carburizing processes do exist as an alternative.

Making the Right Choice for Your Goal

Adopting vacuum furnace technology is a strategic decision that aligns operational performance with environmental responsibility.

- If your primary focus is meeting strict emissions regulations: A vacuum furnace is the definitive choice, as it eliminates direct CO2, NOx, and particulate emissions at your facility.

- If your primary focus is superior material integrity: The clean, controlled environment prevents oxidation and contamination, producing higher-quality parts with longer service lives, which is a key tenet of sustainability.

- If your primary focus is reducing long-term operational costs: The significant gains in energy efficiency and the elimination of consumable process gases can deliver substantial financial savings over the life of the equipment.

By understanding these principles, you can make an informed decision that improves both your product and your environmental stewardship.

Summary Table:

| Environmental Benefit | Key Features |

|---|---|

| Eliminates Direct Emissions | No combustion byproducts, no generated atmospheres, contained operation |

| Maximizes Energy Efficiency | Superior insulation, precise heating, reduced material waste |

| Supports Sustainability | Cleaner parts, lower operational costs, regulatory compliance |

Ready to enhance your lab's sustainability with advanced furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, with deep customization to meet your unique needs. Contact us today to learn how we can help you reduce emissions and improve efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control