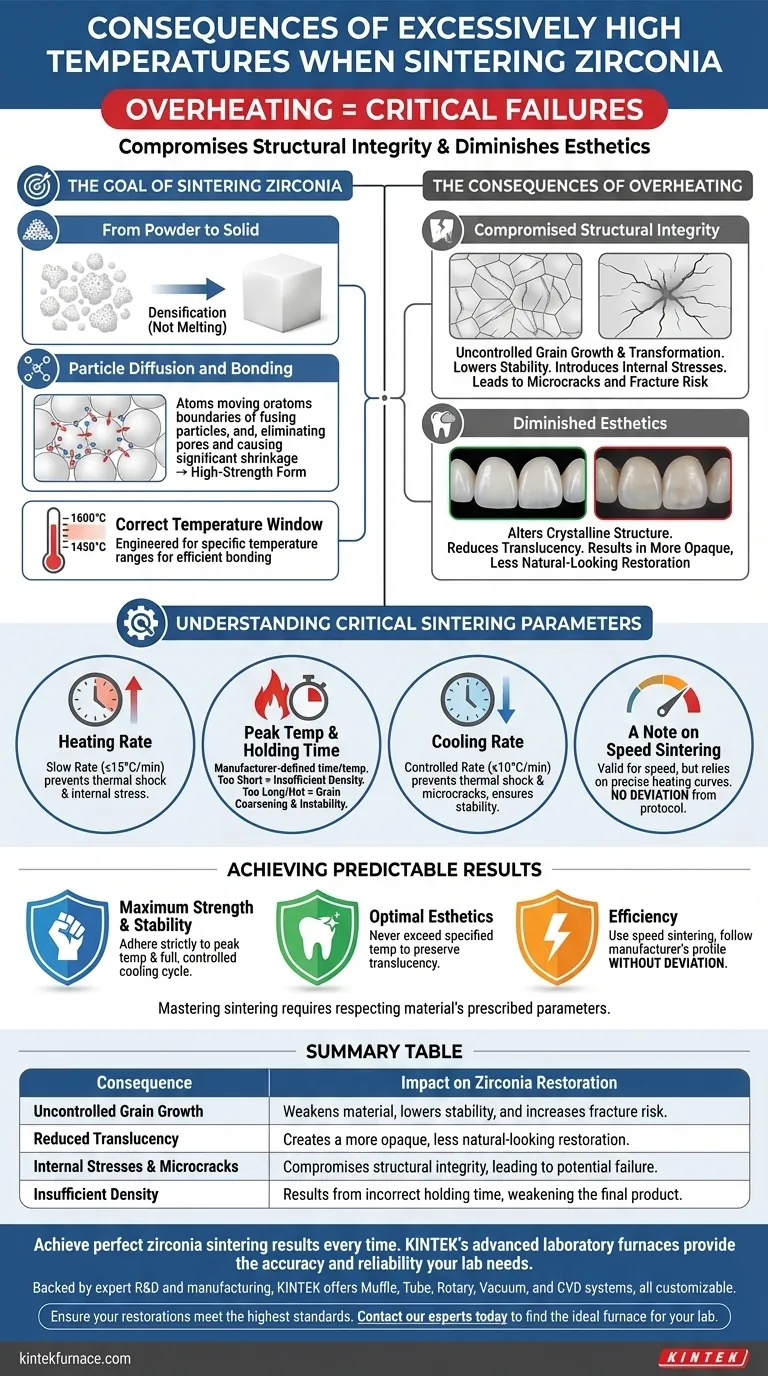

Ultimately, using excessively high temperatures when sintering zirconia leads to critical failures. It compromises the material's structural integrity, causing lowered stability and cracking, while also diminishing the esthetic outcome by reducing translucency.

The core principle of sintering is not about achieving the highest possible temperature, but about maintaining precise control over a full cycle of heating, holding, and cooling. Exceeding the manufacturer's specified temperature introduces instability and degrades the final restoration, providing no benefits and creating significant risks.

The Goal of Sintering Zirconia

From Powder to Solid

Sintering is a process of densification, not melting. Its purpose is to transform a porous, pre-sintered zirconia block into a dense, strong ceramic by heating it below its melting point.

Particle Diffusion and Bonding

The process works by allowing atoms to diffuse across the boundaries of the zirconia particles, fusing them together. This eliminates the pores between particles and causes the material to shrink significantly into its final, high-strength form.

The Correct Temperature Window

Each type of zirconia is engineered for a specific temperature range, typically between 1450°C and 1600°C. This specific temperature provides the necessary energy for particle bonding to occur efficiently without damaging the material's underlying crystal structure.

The Consequences of Overheating

Compromised Structural Integrity

Using a temperature that is too high causes uncontrolled grain growth and transformation. This leads to lowered material stability and can introduce internal stresses that manifest as microcracks, severely weakening the final restoration and making it prone to fracture.

Diminished Esthetics

Excessive heat has a direct, negative impact on the visual properties of the zirconia. It alters the material's crystalline structure in a way that reduces its translucency, resulting in a more opaque and less natural-looking restoration.

Understanding the Critical Sintering Parameters

Heating Rate

The rate at which the furnace temperature increases must be carefully controlled. A slow heating rate, typically ≤15°C per minute, is recommended to prevent thermal shock and avoid building up internal stress that can cause cracking before the peak temperature is even reached.

Peak Temperature and Holding Time

This is the most critical phase. The furnace holds at a specific peak temperature for a set duration, as defined by the zirconia manufacturer. If the holding time is too short, the restoration will have insufficient density. If it is too long or too hot, it leads to grain coarsening and instability.

Cooling Rate

Controlled cooling is just as important as controlled heating. A rapid drop in temperature can cause thermal shock, leading to microcracks. A slow cooling rate, often ≤10°C per minute, allows the restoration to stabilize gradually and ensures its structural integrity.

A Note on Speed Sintering

Rapid sintering cycles are a valid and effective option, often producing restorations with strength equal to or greater than traditional methods. However, these cycles rely on precisely engineered heating curves. Any deviation from the manufacturer's strict protocol negates the benefits and introduces the same risks of cracking and instability.

Achieving Predictable Results

The key to successful zirconia restorations is not brute force but precise control. Adhering strictly to the manufacturer's guidelines for the specific material you are using is non-negotiable for achieving predictable, high-quality outcomes.

- If your primary focus is maximum strength and stability: Adhere strictly to the recommended peak temperature and allow for the full, controlled cooling cycle.

- If your primary focus is optimal esthetics: Never exceed the specified temperature, as this will directly harm the material's translucency.

- If your primary focus is efficiency: Use a speed sintering cycle but follow the manufacturer's heating, holding, and cooling profile without any deviation.

Mastering the sintering process comes from respecting the material's prescribed parameters.

Summary Table:

| Consequence | Impact on Zirconia Restoration |

|---|---|

| Uncontrolled Grain Growth | Weakens material, lowers stability, and increases fracture risk. |

| Reduced Translucency | Creates a more opaque, less natural-looking restoration. |

| Internal Stresses & Microcracks | Compromises structural integrity, leading to potential failure. |

| Insufficient Density | Results from incorrect holding time, weakening the final product. |

Achieve perfect zirconia sintering results every time.

Precise temperature control is non-negotiable for strong, aesthetically pleasing dental restorations. KINTEK's advanced laboratory furnaces provide the accuracy and reliability your lab needs.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique sintering protocols.

Ensure your restorations meet the highest standards. Contact our experts today to find the ideal furnace for your lab.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency