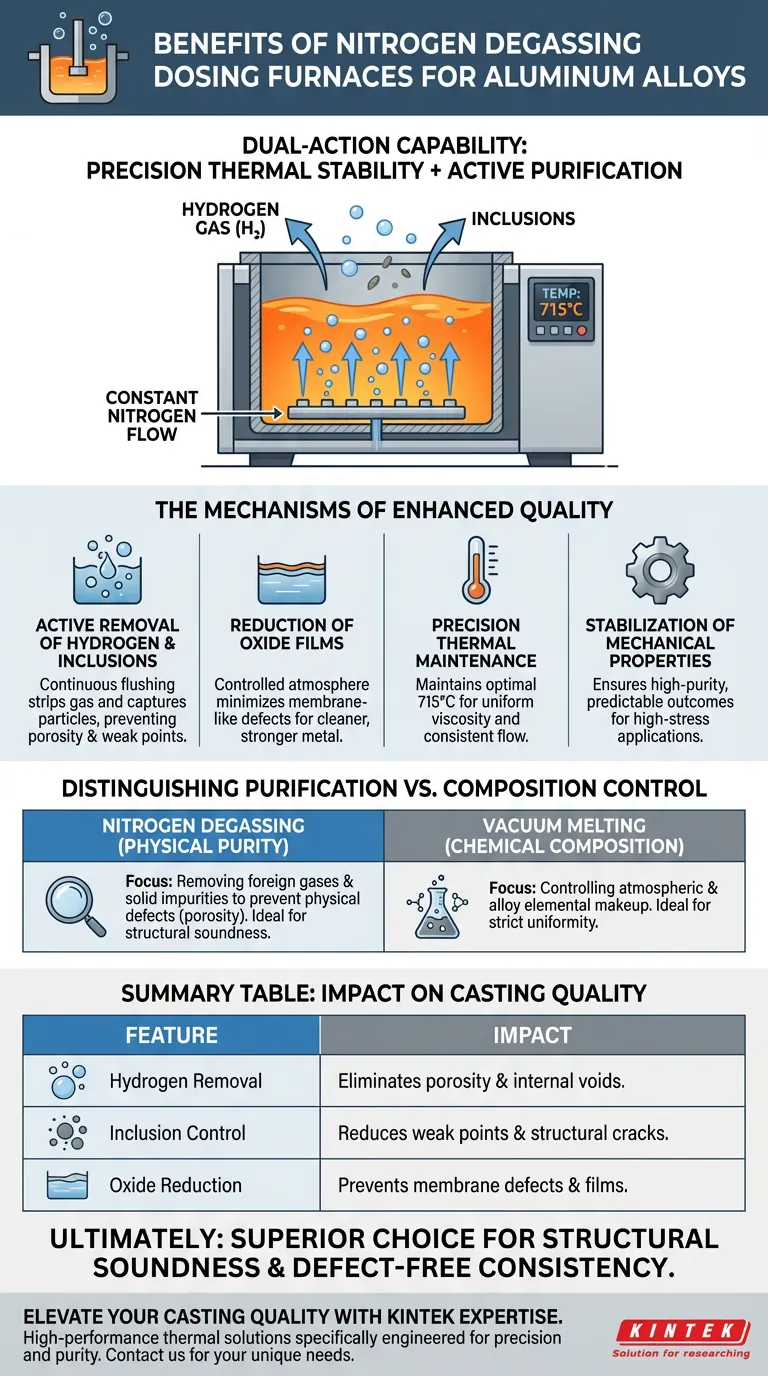

Integrating a constant nitrogen degassing system into a dosing furnace transforms the unit from a simple holding vessel into an active purification stage for aluminum alloy melting. This configuration simultaneously maintains precise thermal conditions—specifically holding the melt at temperatures like 715°C—while aggressively purging the alloy of structural contaminants. The immediate result is a significant reduction in casting defects and a measurable improvement in the consistency of the final product.

Core Takeaway: The system’s value is defined by its dual-action capability: it stabilizes the metal's temperature while actively removing hydrogen and inclusions. This creates a high-purity melt that minimizes oxide formation and ensures uniform mechanical properties across production runs.

The Mechanisms of Enhanced Quality

Active Removal of Hydrogen and Inclusions

The primary threat to aluminum structural integrity is the presence of dissolved hydrogen gas and non-metallic inclusions.

The integrated nitrogen system addresses this by continuously flushing the melt. This process effectively strips hydrogen from the molten aluminum and captures inclusions, preventing porosity in the final casting.

Reduction of Oxide Films

Oxide films are detrimental to the continuity of the metal matrix, often leading to cracks or weak points.

By maintaining a controlled nitrogen interaction, the system significantly reduces the formation of these oxide films. This ensures that the metal flowing into the mold is clean and free of the membrane-like defects that compromise durability.

Precision Thermal Maintenance

Consistency in casting requires absolute control over viscosity and flow characteristics.

The dosing furnace is designed to maintain the molten metal at a specific, optimal temperature, such as 715°C. This thermal stability prevents the segregation of alloying elements and ensures the degassing process occurs at the most efficient efficiency.

Stabilization of Mechanical Properties

The combination of thermal precision and active cleaning leads to predictable outcomes.

By minimizing fluctuations in the melt quality, the system ensures that the resulting aluminum alloy castings exhibit high purity and consistent mechanical properties. This reliability is essential for high-stress applications where margin for error is non-existent.

Distinguishing Purification from Composition Control

The Role of Nitrogen Degassing

It is important to understand that the nitrogen system is primarily a purification tool.

Its main function is to physically remove foreign gases (hydrogen) and solid impurities (inclusions) to prevent physical defects like porosity.

The Role of Vacuum Environments

While nitrogen degassing handles purity, it is distinct from vacuum melting technologies.

As noted in comparative technical data, a vacuum melting furnace is better suited for controlling the chemical atmosphere and alloy composition. If your challenge involves strictly managing the ratio of chemical elements within the alloy rather than removing gas, a vacuum environment offers superior uniformity for that specific parameter.

Making the Right Choice for Your Goal

To select the correct technology, you must align the equipment capabilities with your most critical quality metric.

- If your primary focus is Physical Integrity: Choose the nitrogen degassing dosing furnace to minimize porosity, oxide films, and mechanical variance caused by hydrogen and inclusions.

- If your primary focus is Chemical Composition: Choose a vacuum melting furnace to ensure strict uniformity of the alloy's elemental makeup through atmospheric control.

Ultimately, the nitrogen degassing system is the superior choice for manufacturers prioritizing the structural soundness and defect-free consistency of aluminum castings.

Summary Table:

| Feature | Nitrogen Degassing Dosing Furnace | Impact on Casting Quality |

|---|---|---|

| Hydrogen Removal | Continuous nitrogen flushing | Eliminates porosity and internal voids |

| Inclusion Control | Active capture of non-metallics | Reduces weak points and structural cracks |

| Oxide Reduction | Controlled nitrogen atmosphere | Prevents membrane-like defects and films |

| Thermal Stability | Precise holding (e.g., 715°C) | Ensures uniform viscosity and metal flow |

| Primary Goal | Physical Purity & Integrity | High-durability, defect-free components |

Elevate Your Casting Quality with KINTEK Expertise

Don't let porosity and inclusions compromise your aluminum alloy production. KINTEK provides high-performance thermal solutions, including customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered for precision and purity.

Backed by expert R&D and world-class manufacturing, we help you achieve the exact thermal conditions and material purity your application demands. Whether you need to stabilize mechanical properties or ensure chemical uniformity, our team is ready to design the perfect furnace for your unique needs.

Ready to optimize your melt? Contact us today to speak with a specialist and see how KINTEK can enhance your lab or production efficiency.

Visual Guide

References

- David Servando Cantú-Fernández, Brian Quinn. Mechanical Properties of a Structural Component Processed in High-Pressure Die Casting (HPDC) with a Non-Heat-Treated Aluminum Alloy. DOI: 10.3390/met14030369

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the role of an Argon gas environment in sintering Boron Carbide? Achieve High Density and Prevent Oxidation

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the significance of a high-purity argon protective environment for CuAlMn alloys? Ensure Material Precision

- What factors should be considered when selecting a controlled atmosphere furnace? Ensure Process Success with Expert Guidance

- Why is a controlled atmosphere necessary in industrial debinding furnaces? Master the Switch from Nitrogen to Air

- Why is a N2 Atmosphere Required for Calcining Doped Carbon Nitride? Protect Purity & Boost Crystallinity

- What is the purpose of the 1000 °C pre-annealing treatment for copper foil? Optimize acm-BN Growth Success

- What is a brazing furnace? Achieve Superior, Oxidation-Free Metal Joining