Choosing the right controlled atmosphere furnace requires looking beyond maximum temperature and chamber size. The critical factors are the specific atmospheric process your material requires, the furnace's ability to maintain that atmosphere without contamination, and the precision of its temperature and gas control systems. A failure in any of these areas can compromise or completely ruin your process outcomes.

The selection of a controlled atmosphere furnace is not just about heating a part. It is about investing in a complete environmental system designed to achieve a specific chemical reaction or physical change in a material, where the integrity of the atmosphere is just as critical as the temperature.

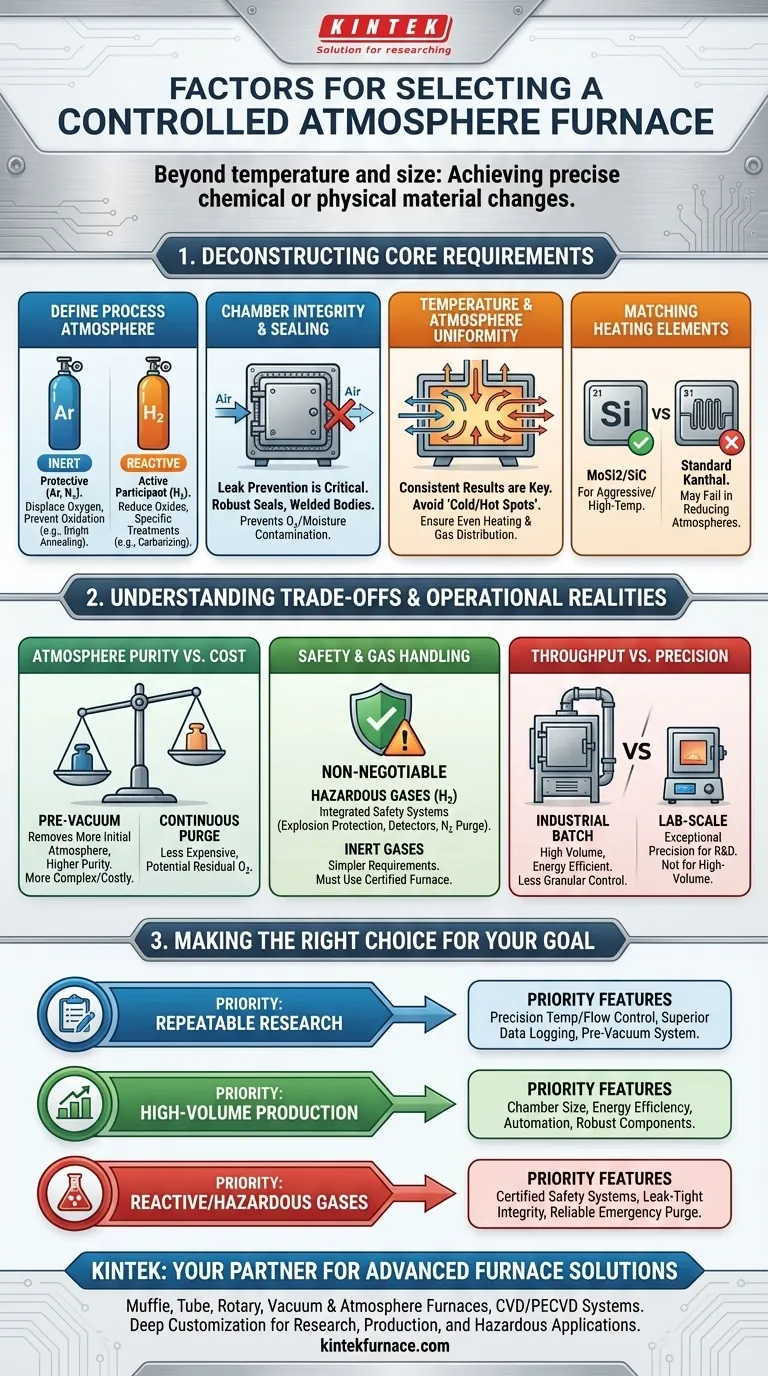

Deconstructing the Core Requirements

To make an informed decision, you must first define your process needs with absolute clarity. The furnace is a tool to serve the process, not the other way around.

Defining Your Process Atmosphere

The type of gas you use dictates everything else. Is your goal to prevent a reaction or to cause one?

An inert atmosphere (like Argon or Nitrogen) is protective. Its purpose is to displace oxygen and prevent oxidation, which is critical for processes like bright annealing or brazing copper.

A reactive atmosphere (like Hydrogen or forming gas) actively participates in the process. It might be used for reducing oxides on a material's surface or for specific carburizing or nitriding heat treatments.

Evaluating Chamber Integrity and Sealing

A furnace's most critical feature is its ability to be sealed. Any leak allows external air (primarily oxygen and moisture) to infiltrate the chamber, contaminating your controlled atmosphere and defeating the entire purpose of the furnace.

Look for robust door seals, welded chamber bodies instead of folded ones, and high-quality fittings for all gas and sensor ports. The integrity of these seals directly determines the purity of the atmosphere you can achieve.

Assessing Temperature and Atmosphere Uniformity

Inconsistent results often stem from poor uniformity. A furnace might reach a setpoint in one location, but "cold spots" or "hot spots" elsewhere in the chamber can lead to improperly treated parts.

Similarly, the gas must be distributed evenly. A poor flow design can create pockets of stagnant or incorrect gas mixtures, resulting in inconsistent surface chemistry across your parts. Ask manufacturers for data on temperature and atmospheric uniformity.

Matching Heating Elements to Your Atmosphere

Not all heating elements are compatible with all atmospheres, especially at high temperatures. For example, using a standard Kanthal (FeCrAl) element in a reducing hydrogen atmosphere can lead to premature element failure.

Molybdenum disilicide (MoSi2) or silicon carbide (SiC) elements are often required for more aggressive or higher-temperature applications. Ensure the heating elements are rated not just for the temperature, but also for the specific chemical environment you plan to use.

Understanding the Trade-offs and Operational Realities

Every furnace design involves compromises. Understanding these trade-offs is key to selecting a furnace that fits your budget and technical requirements without sacrificing critical performance.

Atmosphere Purity vs. Cost

The method used to purge air from the chamber before introducing the process gas significantly impacts purity. A simple continuous gas purge is less expensive but may leave residual oxygen.

For higher purity, a system that can pull a preliminary vacuum before backfilling with gas is superior. This removes far more of the initial atmosphere, but adds complexity and cost. You must decide what level of purity is "good enough" for your process.

Safety and Gas Handling

Safety is non-negotiable, especially with flammable or toxic gases. A furnace intended for use with hydrogen must have integrated safety systems, such as explosion-protection devices, automatic nitrogen purge cycles, and leak detectors.

Systems designed for inert gases have simpler requirements. Never attempt to use a hazardous gas in a furnace not explicitly designed and certified for it.

Throughput vs. Precision

Large, industrial batch furnaces are built for throughput and energy efficiency. They are excellent for processing many parts at once but may offer less granular control than a smaller laboratory furnace.

Conversely, a lab-scale furnace provides exceptional precision for research and development but is not practical for high-volume production. Your choice depends on whether your priority is manufacturing scale or process discovery.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary application. Use this framework to prioritize features.

- If your primary focus is repeatable material research: Prioritize precision temperature and mass flow controllers, superior data logging capabilities, and a system capable of a pre-vacuum for the highest purity.

- If your primary focus is high-volume production (e.g., brazing, sintering): Prioritize chamber size, energy efficiency, automation features, and robust, low-maintenance components to ensure maximum uptime.

- If your primary focus is working with reactive or hazardous gases: Your first priority must be the furnace's certified safety systems, leak-tight chamber integrity, and reliable emergency purge and shutoff capabilities.

A methodical evaluation of these factors ensures your furnace becomes a reliable tool for achieving precise material outcomes.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Process Atmosphere | Inert (e.g., Argon) for protection; Reactive (e.g., Hydrogen) for active processes |

| Chamber Integrity | Robust seals, welded bodies, leak-tight design to prevent contamination |

| Temperature Uniformity | Avoid cold/hot spots; ensure even heating for consistent results |

| Heating Elements | Compatibility with atmosphere (e.g., MoSi2 for high-temp/reactive gases) |

| Atmosphere Purity | Purge methods (continuous vs. pre-vacuum) for desired purity levels |

| Safety | Certified systems for hazardous gases, including leak detectors and purges |

| Throughput vs. Precision | Batch furnaces for volume; lab furnaces for R&D and control |

Ready to elevate your material processing with a tailored controlled atmosphere furnace? At KINTEK, we specialize in providing advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs—whether for research, production, or hazardous gas applications. Contact us today to discuss how our expertise can ensure your process success and boost efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance