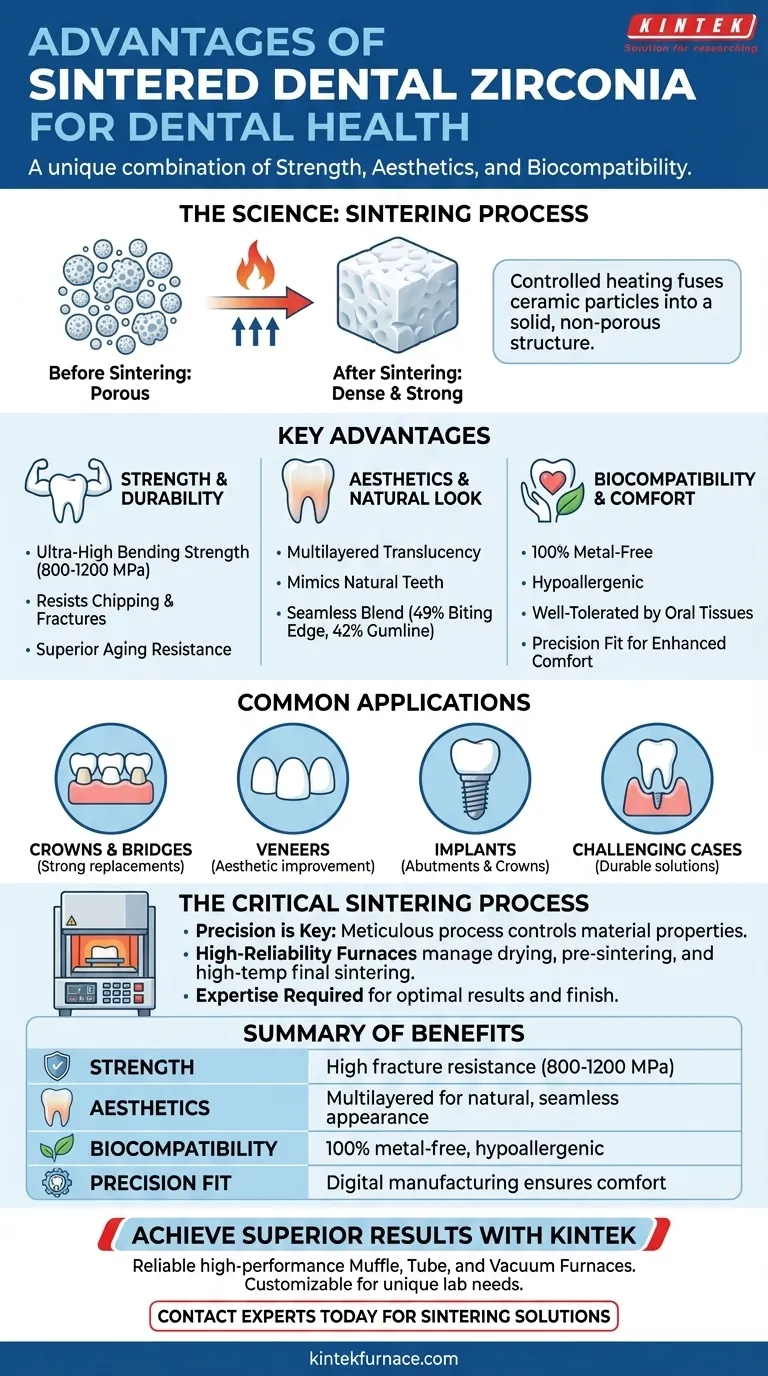

From a technical standpoint, sintered dental zirconia offers significant advantages for dental health by providing a unique combination of superior strength, excellent aesthetics, and high biocompatibility. This advanced ceramic material reduces the risk of metal allergies, blends naturally with existing teeth, and is used to create durable, long-lasting restorations like crowns and bridges.

The core advantage of sintered zirconia lies not in a single feature, but in the controlled heating process (sintering) that transforms a porous material into a dense, ultra-strong ceramic. This delivers a modern dental solution that is simultaneously robust, aesthetically pleasing, and safe for the patient.

The Science Behind Sintered Zirconia's Strength

The remarkable properties of dental zirconia are unlocked through a precise, high-temperature manufacturing process. Understanding this process reveals why it has become a preferred material in restorative dentistry.

What is Sintering?

Sintering is an advanced technological process where zirconia is heated in a specialized furnace under immense pressure. This causes the individual ceramic particles to fuse together, creating a solid, non-porous structure with exceptional density and strength.

Unmatched Durability

The sintering process gives zirconia an ultra-high bending strength, often ranging from 800 to 1200 MPa. This makes it highly resistant to the chipping, cracking, and fractures that can affect other dental materials under the stress of chewing.

Superior Aging Resistance

Modern zirconia formulations are engineered for long-term stability. They effectively resist the natural phase changes that can degrade some ceramics over time, ensuring the restoration maintains its integrity and strength for years.

Key Advantages for Patient Health and Comfort

Beyond its mechanical properties, sintered zirconia provides direct benefits that enhance patient well-being, safety, and confidence.

Biocompatibility and Allergy Prevention

As a metal-free material, zirconia eliminates the risk of allergic reactions commonly associated with metal-based restorations. Its inert nature ensures it is well-tolerated by the body's tissues.

Superior Aesthetics and Natural Appearance

Advanced multilayer zirconia materials mimic the appearance of natural teeth with remarkable accuracy. They feature a natural transition in translucency, for example, from 49% at the biting edge to 42% at the gumline, allowing restorations to blend seamlessly.

Precision Fit and Enhanced Comfort

The use of digital design and temperature-controlled sintering equipment allows for the creation of restorations with exceptional precision. This ensures a comfortable, accurate fit that minimizes adjustments and protects against premature failures.

Understanding the Process and Its Implications

The benefits of zirconia are not inherent to the material alone; they are the direct result of a meticulous and controlled manufacturing process. Poor execution at any stage can compromise the final outcome.

The Critical Role of the Sintering Furnace

High-reliability furnaces are essential for a successful outcome. They manage multiple critical phases, including drying, pre-sintering, and the final high-temperature sintering, ensuring the material is processed evenly and thoroughly.

Precision Requires Expertise

Achieving the desired result is a multi-step procedure involving careful material selection, analysis of sintering conditions, controlled heating and cooling, and finally, expert cleaning, polishing, and inspection. The skill of the dental lab is paramount.

Material Hardness vs. Opposing Teeth

While zirconia's hardness is a key advantage for durability, it also means the final restoration must be perfectly polished. An improperly finished surface can be abrasive and cause premature wear on the opposing natural teeth over time.

Common Applications in Modern Dentistry

Thanks to its versatility and strength, sintered zirconia is used for a wide range of dental procedures, from single-tooth repairs to full-mouth reconstructions.

Crowns and Bridges

Zirconia is an ideal material for fabricating full-ceramic crowns and bridges used to restore weak, damaged, or missing teeth with strong and fully functional replacements.

Veneers and Implants

Its aesthetic properties make it a great choice for veneers designed to improve the look of front teeth. It is also widely used for the abutments and crowns placed on dental implants.

Challenging Restorative Cases

The material's reliability allows clinicians to manage difficult cases that demand a cost-effective, high-quality, and exceptionally durable solution that traditional materials might not provide.

Making the Right Choice for Your Restoration

Your specific goal will determine if sintered zirconia is the optimal material for your needs.

- If your primary focus is aesthetics and a natural look: Multilayered zirconia is an excellent choice, as it offers a seamless blend with your natural teeth.

- If your primary focus is strength and long-term durability: Zirconia's high resistance to fracture makes it ideal for crowns on molars or for multi-tooth bridges.

- If your primary focus is biocompatibility and avoiding metal allergies: The 100% metal-free composition of zirconia provides the ultimate peace of mind.

Ultimately, sintered zirconia represents a powerful convergence of material science and digital technology, offering a safe, beautiful, and resilient solution for modern dental restorations.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Strength & Durability | High fracture resistance (800-1200 MPa) for long-lasting crowns & bridges. |

| Aesthetics | Multilayered translucency (49% to 42%) for a natural, seamless appearance. |

| Biocompatibility | 100% metal-free, hypoallergenic, and well-tolerated by oral tissues. |

| Precision Fit | Digital manufacturing ensures comfortable, accurate restorations. |

Ready to achieve superior results with sintered zirconia?

The precise sintering process is critical to unlocking zirconia's full potential. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum furnaces, all customizable for your lab's unique sintering needs. Ensure consistent, high-quality dental restorations with reliable equipment.

Contact our experts today to discuss how our sintering solutions can enhance your dental lab's capabilities and product quality.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations