The primary advantage of using an induction melting furnace for high-entropy alloys lies in its intrinsic electromagnetic stirring capability. This process utilizes alternating currents to generate rapid heating while simultaneously inducing strong convection currents within the melt pool. This "self-stirring" effect is critical for secondary remelting, as it ensures microscopic uniformity and the consistent distribution of trace refractory elements throughout the alloy matrix.

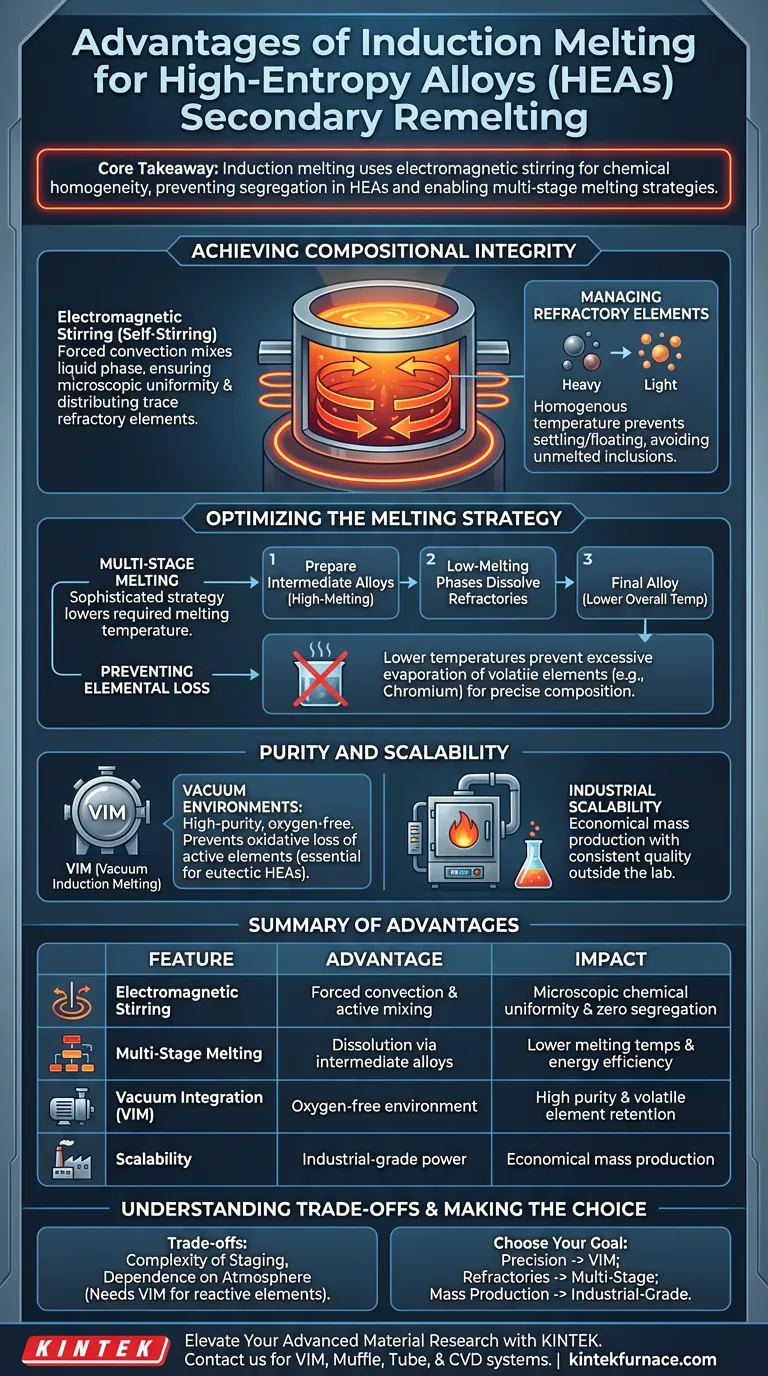

Core Takeaway High-entropy alloys (HEAs) rely on the precise mixture of multiple principal elements, often with vastly different melting points. Induction melting solves the challenge of segregation by using electromagnetic stirring to force chemical homogeneity, while enabling multi-stage melting strategies that prevent the evaporation of volatile components.

Achieving Compositional Integrity

The Power of Electromagnetic Stirring

The defining feature of induction melting is the stirring effect caused by the electromagnetic field. Unlike static melting methods, this technology actively mixes the liquid phase.

This forced convection is essential for HEAs, which often contain five or more metallic elements. It ensures that heavy refractory elements do not settle and that lighter elements do not float, resulting in an ingot with a precise and uniform chemical composition.

Managing Refractory Elements

In secondary remelting, ensuring that high-melting-point (refractory) elements are fully dissolved is a major challenge. The induction process facilitates this by maintaining a homogenous temperature distribution.

The stirring effect ensures that trace additions of these difficult-to-melt elements are dispersed consistently throughout the matrix, preventing the formation of unmelted inclusions or brittle phases.

Optimizing the Melting Strategy

Utilizing Multi-Stage Melting

Induction systems support high energy inputs, allowing for a sophisticated "multi-stage" melting strategy rather than a simple single-step melt.

By preparing intermediate alloys of high-melting-point elements first, manufacturers can utilize a mechanism where low-melting-point phases help dissolve the remaining refractory elements. This effectively lowers the overall melting temperature required for the batch.

Preventing Elemental Loss

Precise compositional control is vital for HEAs, particularly when they contain volatile elements like chromium.

By lowering the overall melting temperature through multi-stage processing, induction melting prevents excessive evaporation loss. This ensures that the final alloy retains its intended compositional ratio, which is critical for maintaining mechanical and corrosion-resistant properties.

Purity and Scalability

The Role of Vacuum Environments

When coupled with a vacuum system (Vacuum Induction Melting or VIM), this technology provides a high-purity environment critical for advanced materials.

A vacuum environment effectively prevents the oxidative loss of active elements during the high-temperature melt. This is particularly important for eutectic HEAs (such as AlCoCrFeNi2.1), ensuring the material retains the mechanical and thermal performance required for aerospace and power generation applications.

Industrial Scalability

Beyond the laboratory, industrial-grade induction furnaces demonstrate that complex concentrated alloys can be manufactured economically.

These systems prove that HEAs are not restricted to small-scale, high-purity lab environments. Industrial induction furnaces provide the necessary stirring and heating power to produce large-scale batches with chemical homogeneity, opening the door for mass production.

Understanding the Trade-offs

While induction melting offers superior homogeneity, it requires careful process design to be effective.

Complexity of Staging: To fully leverage the benefits, you cannot simply melt all elements at once. You must adopt a multi-stage strategy (melting intermediate alloys first) to avoid evaporation issues. This adds complexity to the workflow compared to simpler melting techniques.

Dependence on Atmosphere: While standard induction provides stirring, it does not inherently protect against oxidation. For alloys with highly reactive elements, you must utilize a vacuum induction furnace (VIM). Standard induction in an open atmosphere may still lead to oxide inclusions or element loss if the environment is not strictly controlled.

Making the Right Choice for Your Goal

To maximize the quality of your high-entropy alloys, align your furnace configuration with your specific production targets:

- If your primary focus is Compositional Precision: Prioritize Vacuum Induction Melting (VIM) to prevent the oxidative loss of active elements and ensure exact chemical ratios.

- If your primary focus is Handling Refractory Elements: Utilize a multi-stage melting strategy within the induction furnace to dissolve high-melting phases into low-melting intermediates.

- If your primary focus is Mass Production: Implement industrial-grade induction furnaces to achieve chemical homogeneity at an economically feasible scale outside of the laboratory.

Success in processing high-entropy alloys depends not just on melting the metal, but on mastering the mix through controlled electromagnetic convection.

Summary Table:

| Feature | Advantage for HEA Secondary Remelting | Impact on Final Alloy |

|---|---|---|

| Electromagnetic Stirring | Forced convection and active mixing of liquid phase | Microscopic chemical uniformity and zero segregation |

| Multi-Stage Melting | Dissolution of refractory elements via intermediate alloys | Lower required melting temperatures and energy efficiency |

| Vacuum Integration (VIM) | Oxygen-free melting environment | High purity and prevention of volatile element loss |

| Scalability | Industrial-grade heating and stirring power | Economical mass production with consistent quality |

Elevate Your Advanced Material Research with KINTEK

High-entropy alloys demand precision that standard melting equipment simply cannot provide. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Vacuum Induction Melting (VIM), Muffle, Tube, and CVD systems specifically designed for high-temperature excellence.

Whether you are refining complex concentrated alloys or scaling up laboratory breakthroughs, our customizable furnace solutions ensure chemical homogeneity and superior purity for your unique metallurgical needs.

Ready to master your mix? Contact KINTEK today to discuss your custom project and see how our expertise can accelerate your production goals.

Visual Guide

References

- Yong Wang, Wangzhong Mu. Effect of hafnium and molybdenum addition on inclusion characteristics in Co-based dual-phase high-entropy alloys. DOI: 10.1007/s12613-024-2831-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What advantages do induction furnaces offer for aluminum melting? Boost Speed, Purity, and Efficiency

- What is the function of a vacuum induction furnace with cold copper crucible in Ti-5Al-2.5Sn alloy preparation?

- Why are electromagnetic stirring and repeated melting cycles necessary? Achieving Homogeneity in (AlTiV)100−xCrx Alloys

- Why are induction furnaces popular for alloy manufacturing? Achieve Superior Alloy Homogeneity and Efficiency

- What are the advantages of using a Vacuum Induction Melting Furnace over an ordinary open melting furnace? Achieve Purity and Precision in Metal Production

- What causes the melting of the solid scrap in the arc furnace? Unlock Efficient Steel Production

- How do IGBT induction melting furnaces compare to traditional melting systems? A Generational Leap in Melting Technology

- Which industries commonly use vacuum casting furnaces and for what applications? Discover Key Uses in Aerospace, Medical, and More