At its core, a Fast Slow Dental Sintering Furnace offers the critical advantage of versatility. It combines the rapid processing needed for urgent, everyday cases with the meticulous, controlled environment required for high-aesthetic, complex restorations. This dual-mode capability allows a modern dental lab to optimize both efficiency and quality without compromise, using a single, highly precise piece of equipment.

The central challenge for dental labs is balancing the demand for rapid turnaround with the need for exceptional clinical quality. A Fast Slow furnace directly solves this by providing dedicated, optimized cycles for both speed and high-end aesthetics, ensuring you never have to sacrifice one for the other.

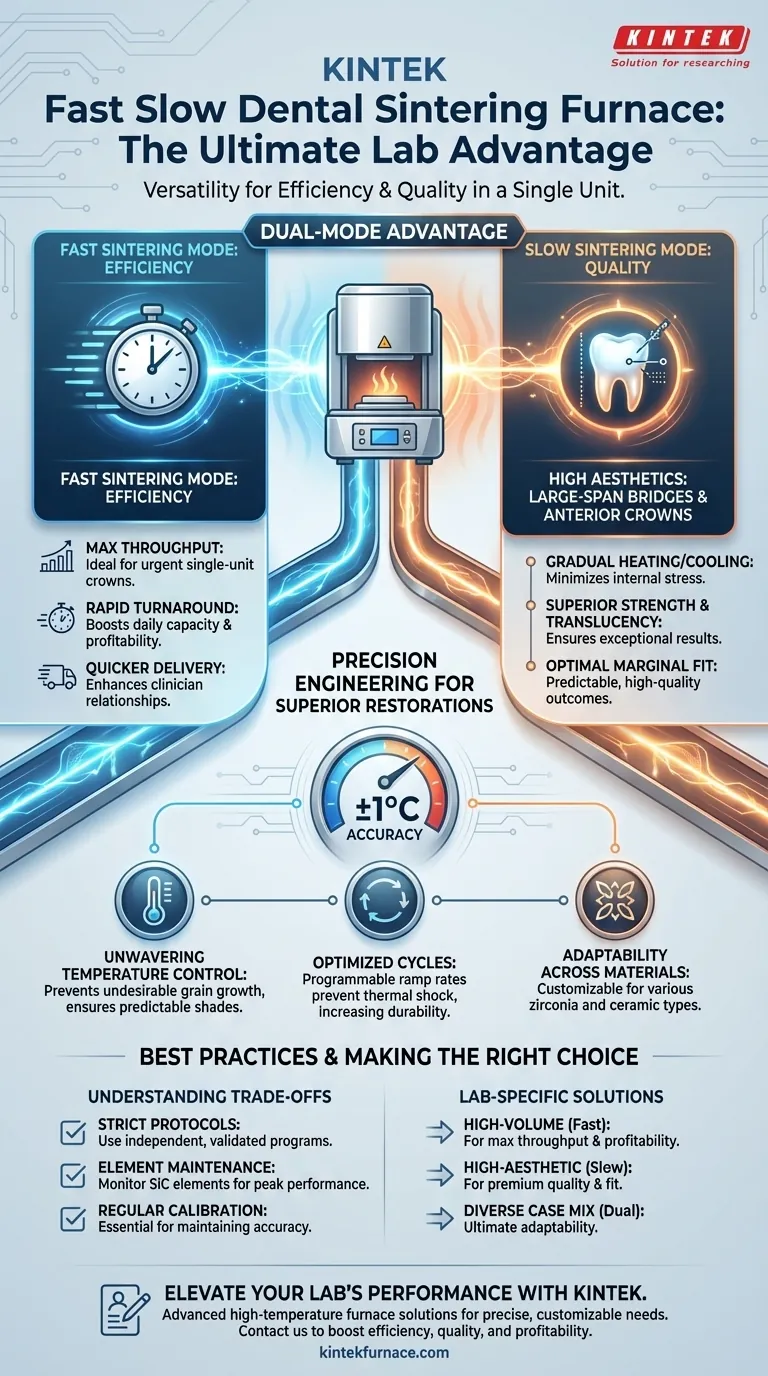

The Dual-Mode Advantage: Speed and Aesthetics on Demand

The most significant benefit is the ability to choose a sintering cycle that perfectly matches the clinical and business need of each case. This flexibility is what separates it from single-purpose furnaces.

The "Fast" Sintering Mode for Efficiency

The fast cycle is engineered for maximum throughput. It is ideal for common restorations like single-unit zirconia crowns where a rapid turnaround time is a key competitive advantage.

By dramatically shortening the production cycle, labs can increase their daily capacity and deliver cases faster, improving relationships with clinicians and increasing profitability.

The "Slow" Sintering Mode for Quality

The slow, conventional cycle is designed for cases that demand the highest aesthetic outcomes, such as large-span bridges or anterior crowns made from high-translucency zirconia.

This mode uses more gradual heating and cooling rates, which minimizes internal stress in the material. The result is a restoration with superior strength, optimal translucency, and exceptional marginal fit.

Precision Engineering for Superior Restorations

Beyond its dual-mode function, the value of a Fast Slow furnace lies in its precise engineering, which guarantees consistent, high-quality results.

Unwavering Temperature Control

These furnaces typically maintain temperature with extreme accuracy, often within ±1°C. This level of control is not a luxury; it is essential for modern ceramic materials.

Precise heat prevents undesirable grain growth in the zirconia structure, ensuring predictable translucency and shade matching. It is the foundation of repeatable, high-quality outcomes.

Optimized Heating and Cooling Cycles

The technology allows for precise programming of ramp rates—the speed at which the furnace heats up and cools down.

Controlled heating and cooling are crucial for preventing thermal shock, which can introduce micro-fractures and compromise the long-term durability of the restoration. This ensures the final product is extremely hard and can withstand significant occlusal force.

Adaptability Across Materials

With customizable programs and precise control, these furnaces are not limited to a single type of zirconia. They can be adapted to sinter a wide variety of ceramic materials from different manufacturers. This adaptability makes the furnace a more versatile and future-proof investment for the lab.

Understanding the Trade-offs and Best Practices

The flexibility of a Fast Slow furnace is its greatest strength, but it requires disciplined use to maintain quality and longevity.

The Need for Strict Protocols

The ability to switch between modes requires careful management. You must use independent, validated sintering programs for different materials and restoration types. Using a fast cycle on a material not designed for it can lead to a compromised result.

Heating Element Considerations

High-performance furnaces often use silicon carbide (SiC) heating elements because of their durability and ability to handle rapid temperature changes. However, these elements are consumables that degrade over time and will require monitoring and eventual replacement to maintain performance.

The Importance of Regular Calibration

To maintain the advertised ±1°C accuracy, the furnace's temperature sensors must be calibrated regularly. Without routine calibration, the core advantage of precision is lost, potentially leading to inconsistent shades, strength, and fit in your restorations.

Making the Right Choice for Your Lab

A Fast Slow Dental Sintering Furnace addresses the central tensions of modern dental lab production. The decision to invest should be based on your lab's specific case mix and business goals.

- If your primary focus is high-volume, single-unit crowns: The fast cycle offers a significant competitive advantage in turnaround time, directly impacting profitability.

- If your primary focus is high-aesthetic, complex bridgework: The precise control and stability of the slow cycle are non-negotiable for ensuring premium quality and fit.

- If your lab handles a diverse mix of cases: The dual-mode flexibility provides the ultimate adaptability to manage any clinical demand without needing multiple furnaces.

Ultimately, this technology empowers a dental laboratory to control its production schedule without ever sacrificing the quality of the final restoration.

Summary Table:

| Advantage | Description |

|---|---|

| Dual-Mode Flexibility | Combines fast cycles for high-volume efficiency and slow cycles for high-aesthetic quality in a single furnace. |

| Precise Temperature Control | Maintains accuracy within ±1°C for consistent results, preventing grain growth and ensuring predictable translucency. |

| Optimized Heating/Cooling | Programmable ramp rates minimize thermal shock, enhancing restoration durability and strength. |

| Material Adaptability | Customizable programs support various zirconia and ceramic materials, offering versatility for diverse cases. |

| Efficiency and Quality | Increases daily capacity with fast cycles while delivering superior marginal fit and aesthetics in slow cycles. |

Ready to elevate your dental lab's performance? KINTEK specializes in advanced high-temperature furnace solutions, including Fast Slow Dental Sintering Furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide precise, customizable equipment to meet your unique needs—boosting efficiency, quality, and profitability. Contact us today to discuss how our tailored solutions can transform your workflow!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations