At its core, speed sintering zirconia offers a powerful combination of time efficiency, cost-effectiveness, and high-quality results. This accelerated process allows dental labs and clinics to produce durable, aesthetic restorations in under an hour, a dramatic reduction from the several hours or overnight cycles required by traditional methods.

The central takeaway is that modern speed sintering is not a compromise on quality for the sake of speed. Instead, it represents a technological leap in furnace control and material science that allows for the rapid, reliable fabrication of high-strength zirconia restorations.

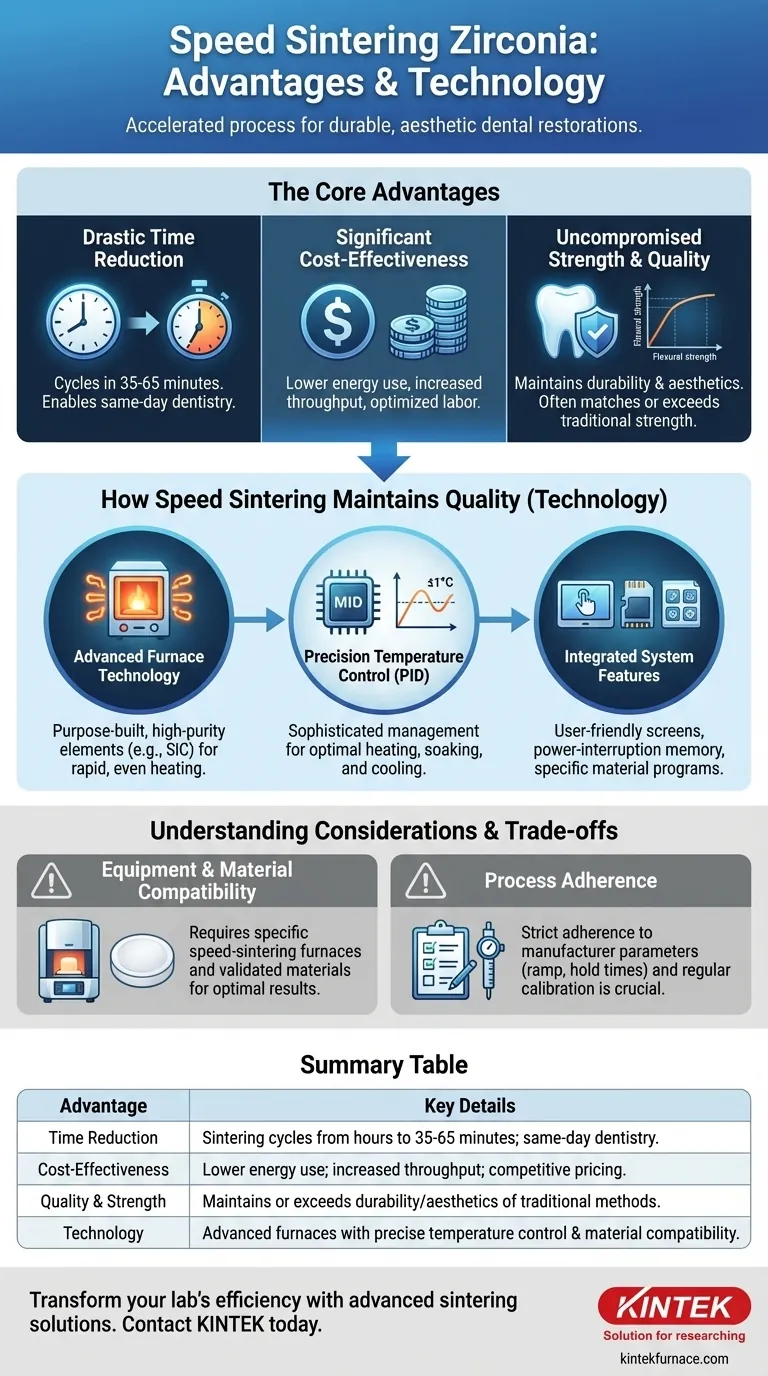

The Core Advantages of Speed Sintering

Speed sintering fundamentally changes the production workflow for zirconia restorations, transforming it from a lengthy, multi-day process into a streamlined, single-day service. This shift is driven by three primary benefits.

Drastic Time Reduction: From Hours to Minutes

The most immediate advantage is the massive reduction in processing time. Traditional sintering can take several hours, often requiring an overnight run in the furnace.

Speed sintering cycles can be completed in as little as 35 to 65 minutes. This capability is the key enabler for same-day dentistry, allowing a clinic to scan, mill, and place a final zirconia crown in a single patient visit.

Significant Cost-Effectiveness

Time saved is directly converted into cost savings. Shorter furnace cycles reduce energy consumption and, more importantly, free up technician time for other value-added tasks.

This increased throughput allows labs to handle urgent cases with greater flexibility and offer more competitive pricing for their restorations without impacting profitability.

Uncompromised Strength and Quality

A common concern with any accelerated process is a potential loss of quality. However, independent research and advancements in furnace technology have shown this is not the case with modern speed sintering.

The process maintains the high standards of durability and aesthetics expected from zirconia. In many cases, the final flexural strength of a speed-sintered restoration is equal to or even greater than one produced via a conventional, slower cycle.

How Speed Sintering Maintains Quality

The reliability of speed sintering is not magic; it is the result of precise engineering and control. The process accelerates the core goal of sintering—the densification and crystallization of the material—through advanced technology.

The Role of Advanced Furnace Technology

Modern speed-sintering furnaces are purpose-built for rapid and precise heating. They use high-purity heating elements, such as specialized silicon molybdenum rods, that can reach target temperatures quickly and distribute heat evenly without contamination.

Precision Temperature Control

These furnaces are governed by sophisticated PID (Proportional-Integral-Derivative) control systems. This allows for incredibly precise temperature management, often with an accuracy of ±1℃.

This level of control ensures the zirconia moves through its heating, soaking, and cooling phases optimally, achieving full density without the risk of thermal shock or incomplete sintering that could compromise the final restoration.

Integrated System Features

Features like user-friendly touch screens, power-interruption memory, and pre-programmed cycles for specific materials make the process repeatable and reliable. The furnace is not just faster; it is a smarter, more controlled system.

Understanding the Trade-offs and Considerations

While the advantages are compelling, adopting speed sintering requires a clear understanding of its operational requirements.

Equipment and Material Compatibility

Speed sintering is not a feature of all furnaces; it requires a modern unit specifically designed for rapid heating and cooling cycles. This represents an initial capital investment.

Furthermore, it is critical to use zirconia materials that have been validated by the manufacturer for specific speed-sintering cycles. Using an unapproved material can lead to poor aesthetic results or compromised strength.

The Need for Process Adherence

The accelerated nature of the process leaves less room for error. Following the manufacturer's recommended parameters for temperature, ramp rates, and hold times is non-negotiable.

Proper calibration and maintenance of the furnace are paramount to ensuring consistent, high-quality outcomes with every cycle.

Making the Right Choice for Your Workflow

Adopting speed sintering is a strategic decision based on your specific operational goals.

- If your primary focus is rapid turnaround and same-day restorations: Speed sintering is an essential technology that directly enables this high-value service.

- If your primary focus is maximizing operational efficiency: The significant reduction in furnace time and associated labor costs delivers a clear and rapid return on investment.

- If your primary focus is delivering the highest quality: Modern speed sintering, when executed with the correct equipment and materials, reliably produces restorations that meet or exceed the strength of those made with traditional methods.

Ultimately, speed sintering elevates the fabrication process from a time-consuming bottleneck into a strategic advantage for your practice or lab.

Summary Table:

| Advantage | Key Details |

|---|---|

| Time Reduction | Sintering cycles from hours to 35-65 minutes, enabling same-day dentistry |

| Cost-Effectiveness | Lower energy use, increased throughput, and competitive pricing |

| Quality and Strength | Maintains or exceeds durability and aesthetics of traditional methods |

| Technology | Advanced furnaces with precise temperature control and material compatibility |

Ready to transform your dental lab's efficiency with advanced sintering solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for speed sintering zirconia. Contact us today to learn how our products can enhance your workflow and deliver superior results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations