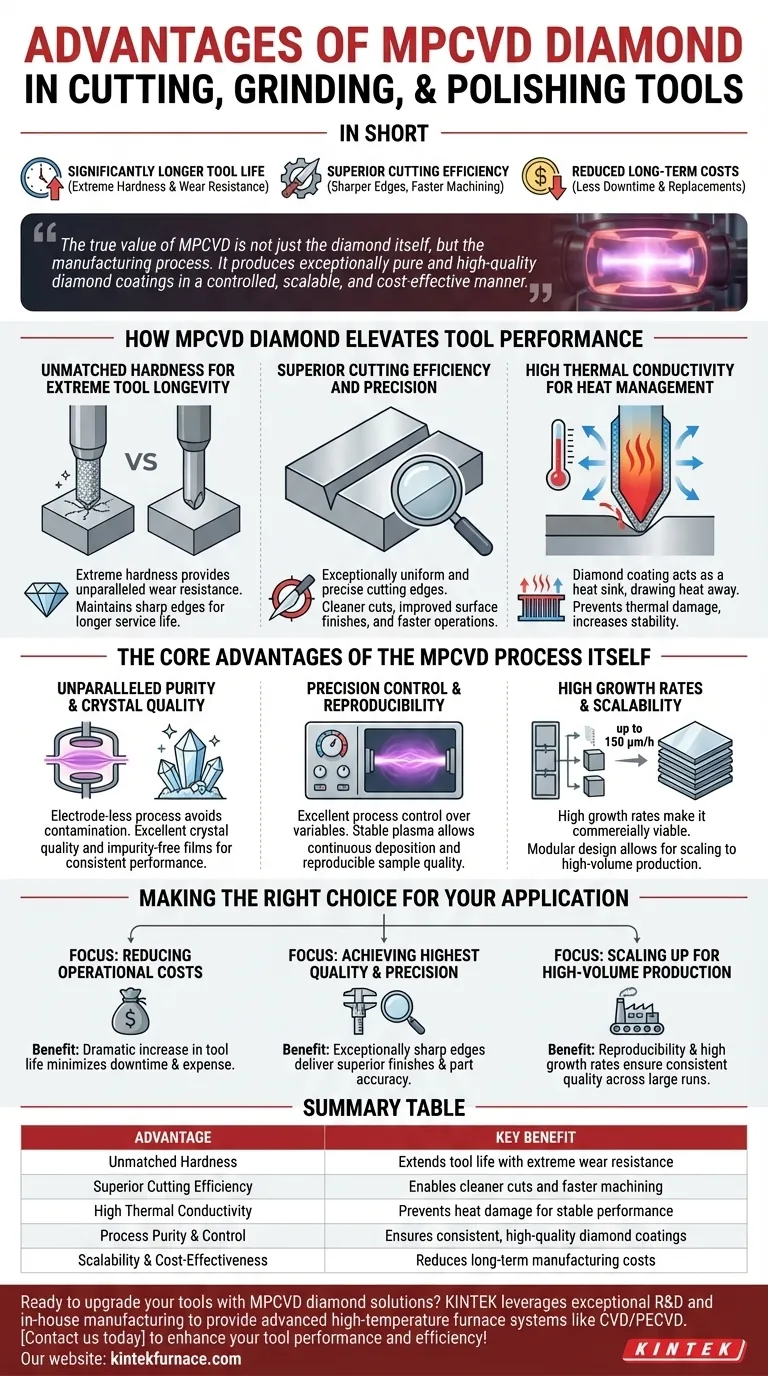

In short, using Microwave Plasma Chemical Vapor Deposition (MPCVD) diamond in cutting, grinding, and polishing tools delivers three primary advantages: significantly longer tool life due to extreme hardness, superior cutting efficiency from sharper and more precise edges, and reduced long-term manufacturing costs by minimizing downtime and the need for frequent tool replacements.

The true value of MPCVD is not just the diamond itself, but the manufacturing process. It produces exceptionally pure and high-quality diamond coatings in a controlled, scalable, and cost-effective manner, making superior tool performance a viable reality for industrial applications.

How MPCVD Diamond Elevates Tool Performance

The benefits of applying an MPCVD diamond coating are directly tied to the fundamental properties of the material it creates. This translates into tangible performance gains in demanding industrial environments.

Unmatched Hardness for Extreme Tool Longevity

Diamond is the hardest known material, and MPCVD produces a high-quality diamond film. This layer of extreme hardness provides unparalleled wear resistance.

Coated tools maintain their sharp cutting edges for far longer than uncoated or traditionally coated counterparts. This directly extends the service life of the tool, a critical factor in industries from aerospace to automotive manufacturing.

Superior Cutting Efficiency and Precision

The MPCVD process allows for the creation of exceptionally uniform and precise cutting edges. This results in cleaner cuts, improved surface finishes on the workpiece, and reduced cutting forces.

This enhanced efficiency not only improves the quality of the final product but can also increase throughput by allowing for faster and more aggressive machining operations.

High Thermal Conductivity for Heat Management

A key, often overlooked, benefit is diamond's exceptional thermal conductivity. During high-speed cutting or grinding, immense heat is generated at the tool tip.

MPCVD diamond coatings act as an effective heat sink, rapidly drawing heat away from the cutting edge. This prevents thermal damage to both the tool and the workpiece, further increasing tool life and process stability.

The Core Advantages of the MPCVD Process Itself

The reason MPCVD has become a preferred method lies in the control and quality it offers over other diamond synthesis techniques. The process itself is what unlocks the material's full potential for industrial use.

Unparalleled Purity and Crystal Quality

MPCVD is an electrode-less process, meaning the plasma used to grow the diamond is generated by microwaves without physical contact. This design inherently avoids contamination from degrading electrodes, which can occur in other methods.

The result is a diamond film with excellent crystal quality and freedom from impurities, ensuring consistent and predictable performance.

Precision Control and Reproducibility

The process offers excellent process control over variables like temperature and gas composition. The microwave-generated plasma is large and highly stable.

This stability allows for continuous deposition over long periods, ensuring reproducible sample quality from one batch to the next. For industrial applications, this consistency is non-negotiable.

High Growth Rates and Scalability

Modern MPCVD systems can achieve high growth rates, with some reaching up to 150 μm/h. This makes coating tools a commercially viable process rather than a laboratory experiment.

Furthermore, the technology features a modular and scalable design. This allows for adaptation to larger substrates and scaling up for high-volume production, making it a cost-effective solution compared to other advanced CVD techniques.

Making the Right Choice for Your Application

Choosing to invest in MPCVD diamond tools is a strategic decision. Your primary operational goal will determine which benefit is most critical for your application.

- If your primary focus is reducing operational costs: The dramatic increase in tool life is the key advantage, as it minimizes downtime and the expense of frequent tool replacement.

- If your primary focus is achieving the highest quality and precision: The ability to create and maintain exceptionally sharp, clean cutting edges will deliver superior surface finishes and part accuracy.

- If your primary focus is scaling up for high-volume production: The reproducibility, high growth rates, and scalability of the MPCVD process ensure you can maintain consistent quality across large manufacturing runs.

Ultimately, MPCVD empowers you to leverage the ideal properties of diamond in a practical and economically sound way.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Unmatched Hardness | Extends tool life with extreme wear resistance |

| Superior Cutting Efficiency | Enables cleaner cuts and faster machining |

| High Thermal Conductivity | Prevents heat damage for stable performance |

| Process Purity & Control | Ensures consistent, high-quality diamond coatings |

| Scalability & Cost-Effectiveness | Reduces long-term manufacturing costs |

Ready to upgrade your tools with MPCVD diamond solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems like CVD/PECVD, tailored for diverse laboratories. Our deep customization capabilities ensure precise solutions for your unique needs in cutting, grinding, and polishing applications. Contact us today to enhance your tool performance and efficiency!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What advantages do MPCVD diamond tools offer in industrial applications? Maximize Lifespan & Efficiency

- How does the ionization degree in MPCVD compare to other methods? Uncover Superior Film Quality and Speed

- How does the MPCVD process work to deposit diamond? A Guide to High-Purity Synthesis

- What is Microwave Plasma Chemical Vapor Deposition (MPCVD)? Unlock Ultra-Pure Diamond Synthesis

- What does CVD stand for and what is its primary function? Discover High-Purity Thin Film Deposition