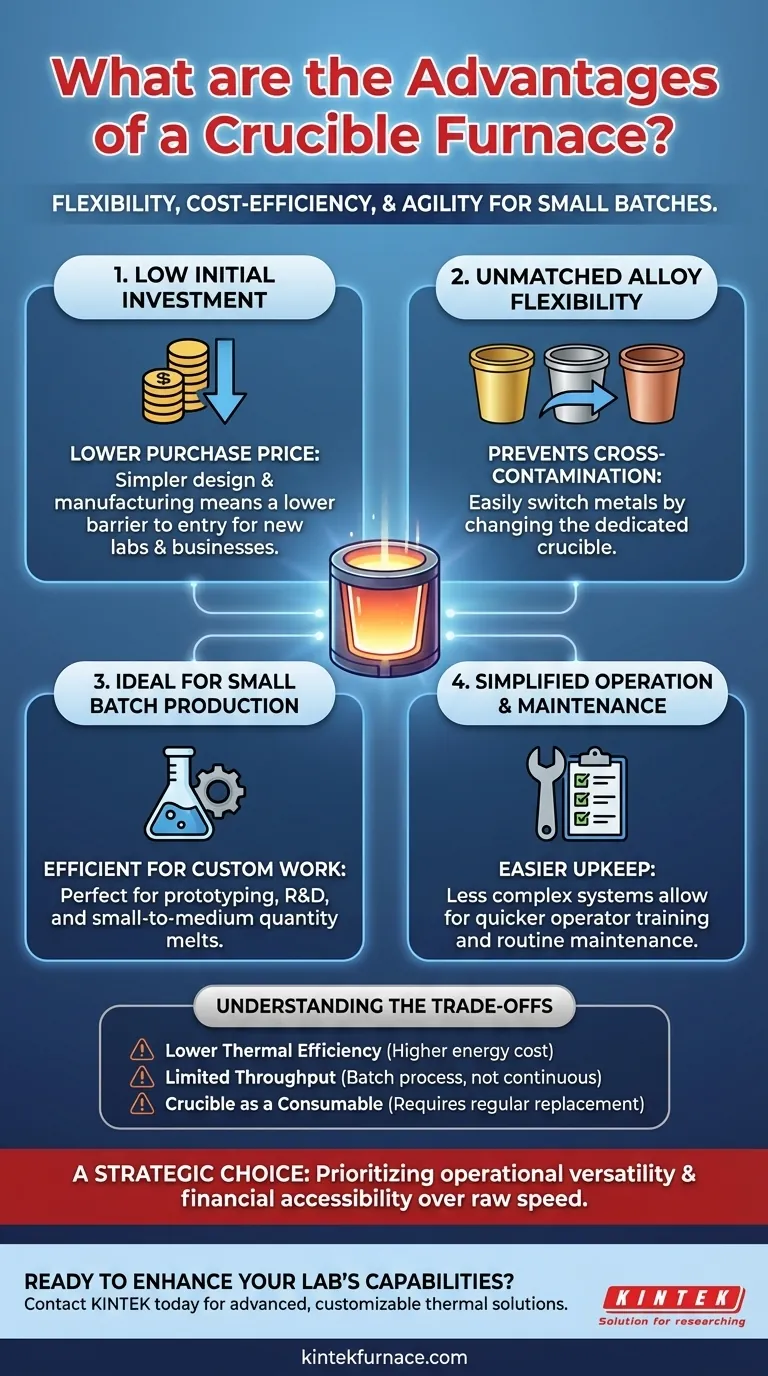

For operations that demand flexibility and cost efficiency, the crucible furnace stands out as a foundational piece of equipment. Its primary advantages are a low initial investment cost, simplicity in operation and maintenance, and the versatility to melt small batches of many different metal alloys without the risk of cross-contamination.

A crucible furnace's true value lies in its agility. By containing each melt within a separate, often interchangeable, crucible, it provides unmatched flexibility for handling diverse alloys and small batch sizes, making it an ideal choice for custom work, prototyping, and multi-alloy foundries.

The Core Advantages Explained

A crucible furnace's design is straightforward: a refractory-lined chamber heats a vessel (the crucible) that contains the metal charge. This simple principle is the source of its key benefits.

Low Initial Investment

The design of a crucible furnace is mechanically and electrically simpler than more advanced systems like induction or arc furnaces.

This simplicity directly translates to a lower manufacturing cost and, therefore, a lower purchase price. For new foundries, small businesses, or labs, this significantly reduces the barrier to entry for in-house melting.

Unmatched Alloy Flexibility

The single most important operational advantage is the ability to melt a wide variety of alloys. Because the molten metal only ever touches the crucible, you can prevent cross-contamination between melts.

A foundry can maintain dedicated crucibles for different metals—one for aluminum, one for bronze, one for a specific zinc alloy. Switching from melting one metal to another is as simple as changing the crucible, a task not feasible in other furnace types where the melt contacts the main furnace lining.

Ideal for Small Batch Production

Crucible furnaces excel at melting small-to-medium quantities of metal. This makes them perfectly suited for operations that don't require continuous, high-volume output.

This is critical for art foundries, custom part manufacturers, and research and development labs. Melting a 20kg batch of a special alloy is highly efficient in a crucible furnace but incredibly wasteful in a multi-ton induction furnace.

Simplified Operation and Maintenance

Fewer complex systems mean easier operation and less demanding maintenance schedules. Operators can be trained quickly, and routine upkeep often consists of inspecting the refractory lining and managing the crucible's lifecycle.

For fuel-fired models, maintenance is focused on the burner system, while electric resistance models require attention to the heating elements. In either case, it is typically less complex than maintaining the power supplies and water-cooling circuits of an induction furnace.

Understanding the Trade-offs

No technology is without its limitations. Objectivity requires acknowledging where a crucible furnace may not be the best fit.

Lower Thermal Efficiency

Heating the crucible from the outside and relying on conduction to transfer that heat to the metal is inherently less efficient than an induction furnace, which heats the metal directly.

This can result in higher energy consumption per kilogram of metal melted, which can become a significant operational cost, especially in high-volume settings.

Limited Throughput and Scalability

The crucible furnace is fundamentally a batch process. Its capacity is limited by the size of the crucible, and the process of heating, melting, and pouring is not continuous.

For large-scale industrial foundries that need to pour thousands of kilograms per hour, the batch nature and slower melt rates of a crucible furnace make it impractical as a primary production unit.

The Crucible as a Consumable

The crucible itself is a consumable item with a finite lifespan. It is subject to extreme thermal shock and chemical attack from molten metal and fluxes.

The cost of regular crucible replacement must be factored into the furnace's total cost of ownership. A sudden crucible failure during a melt is also a significant operational and safety risk.

Making the Right Choice for Your Operation

Choosing a furnace is a strategic decision that must align with your specific production goals.

- If your primary focus is high-volume, single-alloy production: A crucible furnace's batch nature and lower efficiency may not be ideal; explore larger induction or reverberatory furnaces.

- If your primary focus is flexibility for custom work or R&D: The ability to easily switch between small batches of different alloys makes the crucible furnace the superior choice.

- If your primary focus is minimizing initial capital investment: The crucible furnace offers the lowest barrier to entry for establishing a professional metal melting capability.

Ultimately, selecting a crucible furnace is a decision to prioritize operational versatility and financial accessibility over raw production speed and thermal efficiency.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Low Initial Investment | Lower purchase price and barrier to entry for small businesses and labs. |

| Alloy Flexibility | Prevent cross-contamination; easily switch between metals by changing the crucible. |

| Small Batch Efficiency | Ideal for custom work, prototyping, and R&D with small-to-medium quantities. |

| Simple Operation & Maintenance | Easier to operate and maintain than complex systems like induction furnaces. |

Ready to enhance your lab's metal melting capabilities with flexibility and cost-efficiency?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions. Our product line, including Crucible, Muffle, Tube, and Vacuum Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Whether you're in R&D, a custom foundry, or a lab prioritizing versatility, our crucible furnace solutions can help you achieve superior results. Contact us today to discuss your specific needs and discover the perfect furnace for your operation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents