The term "vacuum tube" can refer to two distinct technologies: the classic electronic components used in audio and radio frequency (RF) applications, or the core of a modern industrial vacuum furnace. For electronics, their key advantage is their highly linear, musical sound profile. For industrial furnaces, the primary benefits are superior process control, safety, and the ability to produce high-quality, defect-free materials.

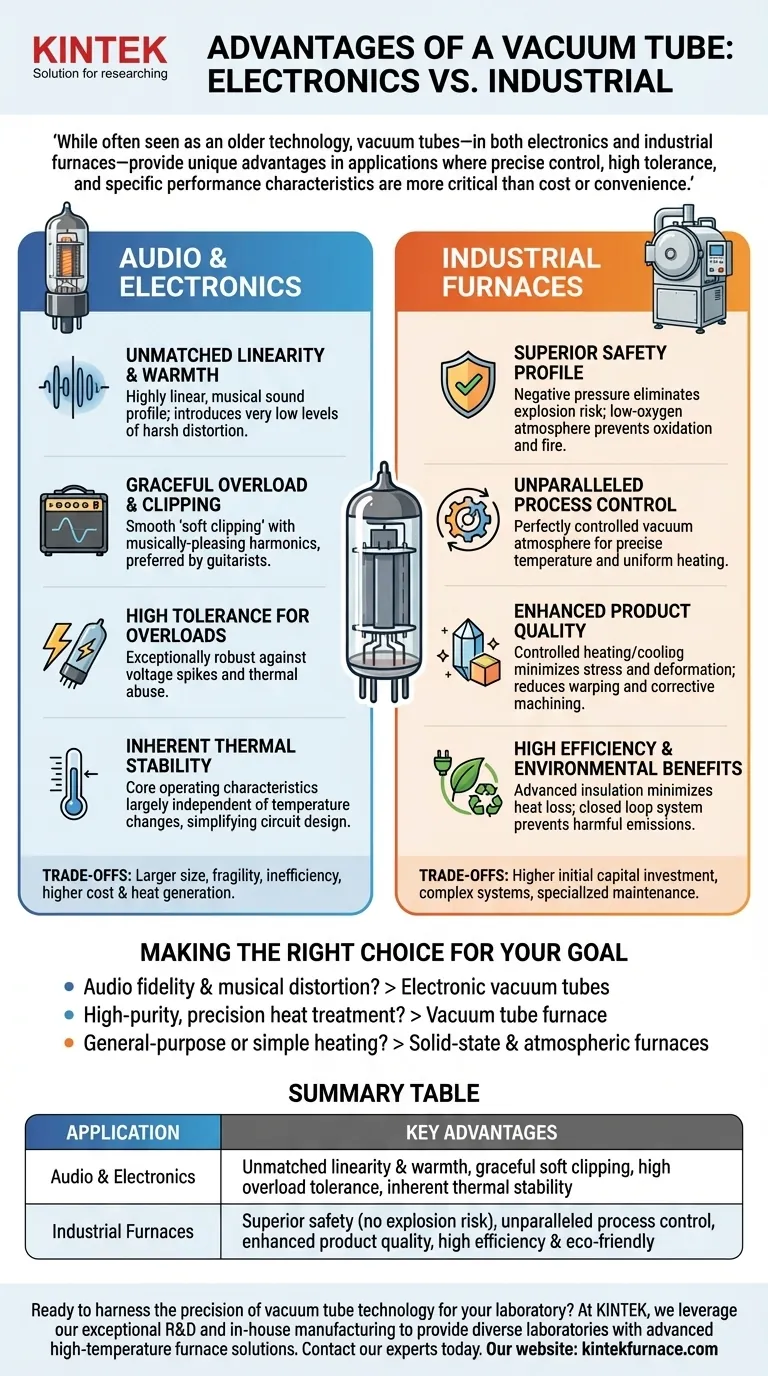

While often seen as an older technology, vacuum tubes—in both electronics and industrial furnaces—provide unique advantages in applications where precise control, high tolerance, and specific performance characteristics are more critical than cost or convenience.

Advantages in Audio and Electronics

The classic vacuum tube, or thermionic valve, remains relevant in high-end audio and specific RF circuits due to its unique electrical properties. These advantages are difficult to replicate with solid-state transistors.

Unmatched Linearity and "Warmth"

Vacuum tubes, particularly small-signal types, are inherently highly linear without requiring large amounts of negative feedback.

This natural linearity contributes to a sound that many audiophiles describe as "warm," "rich," or more natural, as it introduces very low levels of the harsh-sounding, high-order distortion common in poorly designed solid-state circuits.

Graceful Overload and Clipping

When a vacuum tube is pushed beyond its operational limits into overload, it tends to clip the signal smoothly.

This "soft clipping" produces lower-order, musically-pleasing harmonics. In contrast, transistors often clip abruptly ("hard clipping"), creating a dense spectrum of harsh, non-musical harmonics. This is why guitarists often prefer tube amplifiers for their desirable distortion characteristics.

High Tolerance for Overloads

Tubes are exceptionally robust when faced with large overloads and voltage spikes.

Their physical construction allows them to absorb momentary electrical and thermal abuse that would instantly destroy a delicate transistor, making them highly reliable in demanding high-power and high-voltage applications.

Inherent Thermal Stability

The core operating characteristics of a vacuum tube are largely independent of temperature changes.

This simplifies circuit design, especially regarding biasing, which is the process of setting the component's baseline operating conditions. Transistor performance, conversely, can drift significantly with temperature, often requiring complex compensation circuits.

Advantages in Industrial Furnaces

A vacuum tube furnace uses a sealed tube under a vacuum to perform high-temperature processes like sintering, carburizing, and annealing. Their advantages stem from the controlled vacuum environment.

Superior Safety Profile

These furnaces operate at negative pressure, which physically eliminates the risk of explosion that can exist in pressurized vessels.

Furthermore, the low-oxygen vacuum atmosphere prevents the oxidation of materials and removes the risk of fire, making them fundamentally safer than conventional furnaces for many processes.

Unparalleled Process Control

A vacuum provides a perfectly controlled atmosphere, free from contaminants that could react with the workpiece.

This allows for extremely precise temperature control and uniform heating along the entire length of the tube, ensuring consistent and repeatable results that are critical in laboratory and high-tech manufacturing.

Enhanced Product Quality

The ability to control heating and cooling rates with precision minimizes thermal stress and deformation. This is especially beneficial for parts with complex shapes.

Processes like vacuum quenching after carburizing can significantly reduce warping, leading to a higher-quality final product that requires less corrective machining, thereby saving time and cost.

High Efficiency and Environmental Benefits

Modern vacuum furnaces use advanced insulation and heating technology to minimize heat loss and reduce energy consumption.

Because the system is a closed loop, it prevents the release of harmful exhaust gases or wastewater into the environment, easily meeting strict regulatory standards and lowering operational costs.

Understanding the Trade-offs

While powerful, neither technology is a universal solution. Understanding their downsides is key to making an informed decision.

For Electronic Tubes: The Cost of Character

The primary disadvantages of electronic vacuum tubes compared to transistors are their size, fragility, and inefficiency. They consume significant power, generate substantial heat, have a limited lifespan, and are far more expensive.

For Industrial Furnaces: The Cost of Control

Vacuum tube furnaces represent a higher initial capital investment compared to standard atmospheric furnaces. They also involve more complex systems (vacuum pumps, seals, and controls) that can require specialized maintenance, increasing their overall operational complexity.

Making the Right Choice for Your Goal

To select the correct technology, you must first define your primary objective.

- If your primary focus is audio fidelity and musical distortion: Electronic vacuum tubes remain the superior choice for high-end amplifiers and specific audio applications.

- If your primary focus is high-purity, precision heat treatment of materials: A vacuum tube furnace provides an unparalleled level of safety, control, and quality.

- If your primary focus is general-purpose electronics or simple heating processes: Modern solid-state components and conventional atmospheric furnaces offer a more cost-effective and convenient solution.

Ultimately, choosing a vacuum tube technology is a deliberate decision to prioritize its specialized performance advantages for a specific, demanding task.

Summary Table:

| Application | Key Advantages |

|---|---|

| Audio & Electronics | Unmatched linearity & warmth, graceful soft clipping, high overload tolerance, inherent thermal stability |

| Industrial Furnaces | Superior safety (no explosion risk), unparalleled process control, enhanced product quality, high efficiency & eco-friendly |

Ready to harness the precision of vacuum tube technology for your laboratory?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Whether your work requires a standard Muffle or Tube Furnace, or a highly customized Vacuum & Atmosphere Furnace or CVD/PECVD System, our deep customization capability ensures your unique experimental requirements are met precisely.

Contact our experts today to discuss how our vacuum tube furnaces can enhance your process control, safety, and product quality.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis