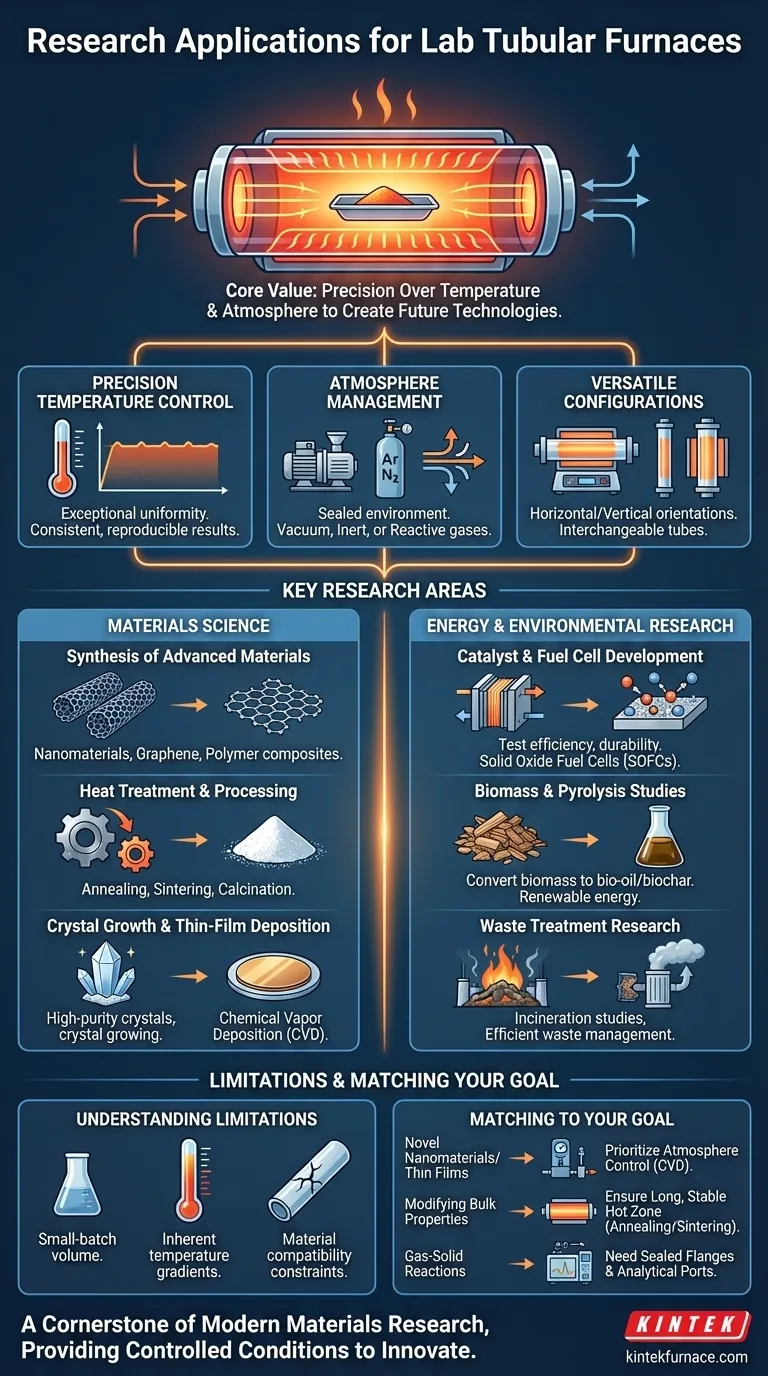

In research, lab tubular furnaces are used for a wide range of high-temperature applications where precise control is paramount. Key examples include synthesizing advanced nanomaterials like carbon nanotubes, testing catalyst performance for fuel cells, heat-treating metals and ceramics through processes like annealing, and studying biomass conversion for renewable energy.

The core value of a tubular furnace is not just its ability to generate high heat, but its power to create a highly controlled and isolated environment. This precision over temperature and atmosphere is what enables researchers to create, modify, and test the materials that define future technologies.

The Foundation: A Precisely Controlled Thermal System

A tubular furnace’s utility comes from its unique ability to manage the three critical variables of materials research: temperature, atmosphere, and physical form.

Precision Temperature Control

The defining feature is a heated chamber that provides exceptional temperature uniformity across a sample. This ensures that experimental results are consistent and reproducible, which is fundamental for reliable research in materials science and chemistry.

Atmosphere Management

Unlike an open-air furnace, the sealed tube allows for complete control over the gaseous environment. Researchers can create a vacuum, introduce an inert gas (like argon or nitrogen) to prevent oxidation, or use a reactive gas to facilitate specific chemical processes.

Versatile Configurations

Tubular furnaces come in horizontal or vertical orientations. Vertical furnaces are particularly useful for controlling temperature gradients or for processes like crystal growth. Many systems also allow for interchangeable tubes of different diameters, accommodating a wide variety of sample sizes and materials.

Key Research Applications in Materials Science

The controlled environment of a tubular furnace is the bedrock for fabricating and testing next-generation materials.

Synthesis of Advanced Materials

These furnaces are central to creating materials with novel properties. This includes the synthesis of nanomaterials like carbon nanotubes and metal oxide nanoparticles, the creation of graphene, and the development of advanced polymer composites.

Heat Treatment and Processing

Tubular furnaces are essential for modifying the properties of existing materials. Common processes include:

- Annealing: Heating and slowly cooling a material to reduce hardness and increase ductility.

- Sintering: Fusing powders (like ceramics or metals) into a solid mass using heat without melting.

- Calcination: Heating a solid material to drive off volatile substances or induce a phase transition.

Crystal Growth and Thin-Film Deposition

Precise thermal control is critical for growing single, high-purity crystals for electronics or research. They are also used for Chemical Vapor Deposition (CVD), a process where a thin film is deposited onto a substrate from a reactive gas, foundational for semiconductor manufacturing.

Applications in Energy and Environmental Research

Beyond fundamental materials science, tubular furnaces are workhorses in the search for cleaner energy and environmental solutions.

Catalyst and Fuel Cell Development

Researchers use tube furnaces to test the efficiency and durability of catalysts, often by flowing specific gases over the catalytic material at high temperatures. This is crucial for developing technologies like solid oxide fuel cells (SOFCs) by studying reaction kinetics.

Biomass and Pyrolysis Studies

Pyrolysis is the thermal decomposition of materials at high temperatures in an inert atmosphere. Researchers use tube furnaces to convert biomass into bio-oil and biochar, analyzing the resulting products to advance renewable energy technologies.

Waste Treatment Research

The same pyrolysis principles can be applied to environmental science. Furnaces are used to study processes like the incineration of solid waste, helping to develop more efficient and less polluting methods of waste management.

Understanding the Limitations

While incredibly versatile, a tubular furnace is not the right tool for every job. Understanding its limitations is key to effective experimental design.

Limited Sample Volume

Tubular furnaces are designed for laboratory-scale research and small-batch production. Their size makes them unsuitable for mass production or processing large components.

Inherent Temperature Gradients

While temperature uniformity is excellent in the central hot zone, gradients will always exist toward the cooler ends of the tube. This can be a limitation for very long samples but can also be leveraged as a feature in certain experiments.

Material and Chemical Compatibility

The process tube itself (often quartz, alumina, or mullite) has temperature and chemical resistance limits. Aggressive chemical precursors or extreme temperatures can damage the tube, requiring careful material selection for the planned experiment.

Matching the Furnace to Your Research Goal

To select or properly utilize a tubular furnace, align its capabilities with your primary objective.

- If your primary focus is creating novel nanomaterials or thin films: Prioritize a system with excellent atmosphere control, including multiple gas inputs and vacuum capability, for processes like CVD.

- If your primary focus is modifying bulk material properties: Ensure the furnace has a long and stable central hot zone for superior temperature uniformity, critical for annealing or sintering.

- If your primary focus is studying gas-solid chemical reactions: You need a furnace with sealed flanges, gas flow controllers, and ideally, ports for connecting to analytical equipment like a gas chromatograph.

Ultimately, the tubular furnace serves as a cornerstone of modern materials research, providing the controlled conditions necessary to innovate and discover.

Summary Table:

| Application Area | Key Examples |

|---|---|

| Materials Science | Nanomaterials synthesis (e.g., carbon nanotubes), heat treatment (annealing, sintering), crystal growth, CVD for thin films |

| Energy Research | Catalyst testing for fuel cells, biomass pyrolysis for bio-oil, solid oxide fuel cell development |

| Environmental Studies | Waste incineration research, pyrolysis for renewable energy |

| General Capabilities | Precision temperature control, atmosphere management (vacuum, inert/reactive gases), versatile configurations (horizontal/vertical) |

Ready to elevate your research with precision high-temperature solutions? KINTEK specializes in advanced tubular furnaces and custom systems tailored for materials science, energy, and environmental applications. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Tube Furnaces, CVD/PECVD Systems, and more, with deep customization to meet your unique experimental needs. Contact us today to discuss how we can enhance your lab's capabilities and drive innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety