At their core, high-temperature vacuum furnaces are used to process advanced materials for critical industries like aerospace, medical, and electronics. They enable processes such as sintering, brazing, and purification at temperatures often exceeding 1200°C, creating components like jet engine turbine blades, medical implants, and semiconductor wafers.

The crucial function of a high-temperature vacuum furnace is not just to generate extreme heat, but to create an ultra-pure, controlled environment. By removing air and other gases, the furnace prevents contamination and unwanted chemical reactions, which is the only way to achieve the required strength, purity, and performance in today's most advanced materials.

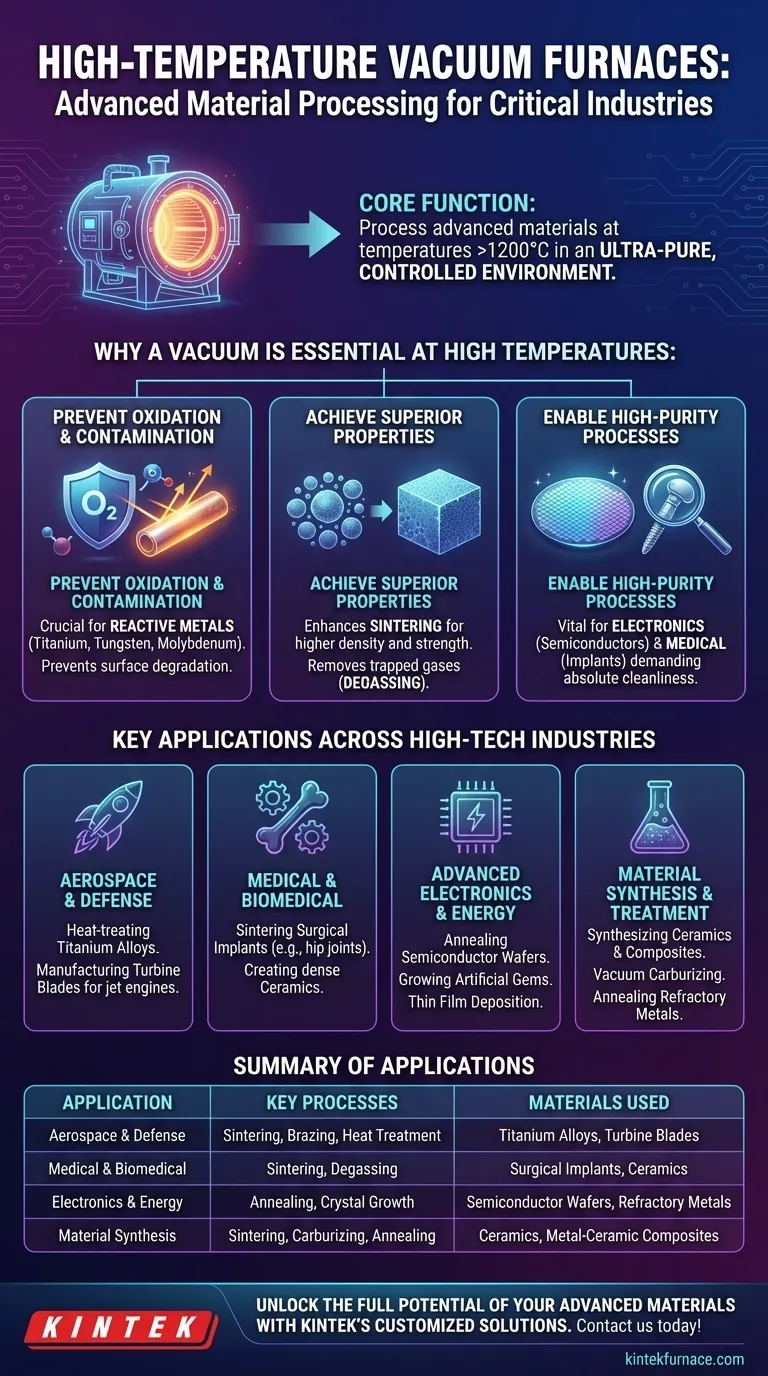

Why a Vacuum is Essential at High Temperatures

Operating at extreme temperatures makes materials highly susceptible to their environment. A vacuum furnace directly addresses this challenge by controlling the atmosphere, which is fundamental to the outcome of the process.

Preventing Oxidation and Contamination

At high temperatures, most materials become extremely reactive. If exposed to air, even trace amounts of oxygen or nitrogen can cause oxidation and form unwanted compounds on the material's surface, compromising its integrity.

The vacuum removes these reactive gases. This is indispensable when working with reactive metals like titanium, tungsten, and molybdenum, which would be ruined by heat treatment in a normal atmosphere.

Achieving Superior Material Properties

The pristine environment of a vacuum allows for the creation of materials with exceptional characteristics. Processes like sintering, which fuses powdered materials into a solid mass, achieve higher density and strength in a vacuum because there are no trapped gases to create pores or impurities.

Similarly, degassing in a vacuum removes dissolved gases from within a metal, a critical step for improving its structural and electrical properties.

Enabling High-Purity Processes

Industries like electronics and medical manufacturing demand absolute purity. For semiconductor wafers or crystal growth, any foreign particle can disrupt the atomic lattice and render the component useless.

For medical implants, a perfectly clean and sterile surface is non-negotiable for ensuring biocompatibility and preventing rejection by the body. A vacuum furnace provides the sterile, contaminant-free environment needed for these applications.

Key Applications Across High-Tech Industries

The unique capabilities of high-temperature vacuum furnaces make them indispensable for manufacturing components that must perform flawlessly under extreme conditions.

Aerospace and Defense

This sector relies on furnaces to create parts that are both lightweight and incredibly strong. Key applications include heat-treating titanium alloys for airframes and manufacturing single-crystal turbine blades for jet engines that can withstand immense temperatures and stress.

Medical and Biomedical

In the medical field, the focus is on purity and biocompatibility. Furnaces are used to sinter materials for surgical implants (like hip joints) and to create dense, non-porous ceramic and metal components for various medical devices.

Advanced Electronics and Energy

The production of modern electronics is a process of extreme precision. Furnaces are used for annealing semiconductor wafers, growing large-scale artificial gems, and depositing thin films—all processes where atomic-level purity is paramount.

Material Synthesis and Treatment

These furnaces are also central to materials science research and specialized industrial processes. This includes synthesizing new ceramics and metal-ceramic composites, performing vacuum carburizing to harden steel surfaces, and annealing refractory metals to relieve internal stresses and improve ductility.

Understanding the Operational Context

While powerful, a high-temperature vacuum furnace is a specialized tool. Understanding its specific role is key to appreciating its value.

The Significance of 1200°C

Many heat treatments for standard steel alloys occur below 1200°C. High-temperature vacuum furnaces are typically reserved for the more demanding processes above this threshold, where exotic materials and extreme purity are the primary concerns.

It's About Control, Not Just Heat

The defining feature of this technology is the precise, simultaneous control over both temperature and atmosphere. This level of control is what allows engineers to fine-tune a material's final properties, from its grain structure to its surface finish.

Process-Specific Environments

Not all processes are the same. Brazing (joining materials) may require a specific vacuum level to ensure the filler metal flows correctly, while sintering might prioritize temperature uniformity and a slow cooling cycle to prevent cracking. The furnace must be capable of managing these distinct process parameters.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on the material you are working with and the properties you need to achieve.

- If your primary focus is maximum strength in reactive metals (e.g., aerospace parts): A high-temperature vacuum is essential to prevent oxidation and ensure the alloy reaches its full performance potential.

- If your primary focus is ultra-high purity (e.g., semiconductors, medical implants): The vacuum environment is the only way to eliminate microscopic contaminants that would cause component failure or biocompatibility issues.

- If your primary focus is general heat treatment of standard steels: A high-temperature vacuum furnace is likely unnecessary; conventional atmospheric or lower-temperature vacuum furnaces are often more suitable and cost-effective.

Ultimately, the high-temperature vacuum furnace is the enabling technology behind the materials that define modern innovation.

Summary Table:

| Application | Key Processes | Materials Used |

|---|---|---|

| Aerospace & Defense | Sintering, Brazing, Heat Treatment | Titanium Alloys, Turbine Blades |

| Medical & Biomedical | Sintering, Degassing | Surgical Implants, Ceramics |

| Electronics & Energy | Annealing, Crystal Growth | Semiconductor Wafers, Refractory Metals |

| Material Synthesis | Sintering, Carburizing, Annealing | Ceramics, Metal-Ceramic Composites |

Unlock the full potential of your advanced materials with KINTEK's high-temperature vacuum furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior purity, strength, and performance for industries such as aerospace, medical, and electronics. Contact us today to discuss how we can optimize your thermal processes and drive innovation in your projects!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes