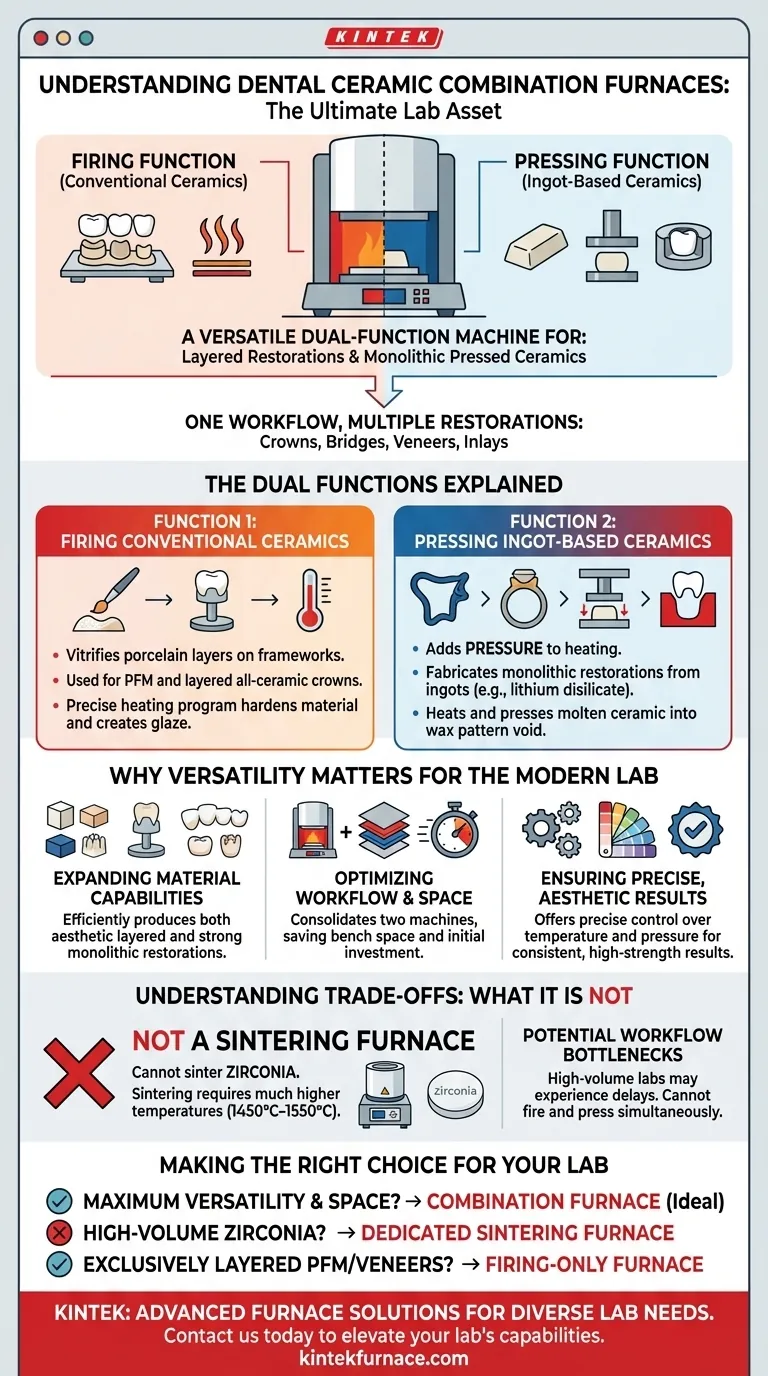

In essence, a dental ceramic combination furnace is a single, versatile piece of laboratory equipment designed to perform two distinct but critical functions: the conventional firing of layered ceramics and the heat-pressing of ingot-based ceramics. This dual capability allows dental technicians to create a wide range of restorations, from crowns and bridges to veneers and inlays, using multiple types of ceramic materials within a single, efficient workflow.

A combination furnace is not merely a piece of equipment; it's a strategic asset for a dental lab. Its primary value lies in consolidating the functions of two separate machines—a firing furnace and a press furnace—into one unit, maximizing versatility, saving space, and expanding a lab's restorative capabilities.

The Dual Functions of a Combination Furnace

To understand the value of a combination furnace, you must first understand the two core processes it facilitates. These processes correspond to different types of ceramic restorations and fabrication techniques.

Function 1: Firing Conventional Ceramics

This is the traditional method for creating restorations like porcelain-fused-to-metal (PFM) crowns or layered all-ceramic crowns. The furnace acts as a high-temperature oven.

The technician applies layers of ceramic powder mixed with a liquid onto a core or framework. The restoration is then placed in the furnace, which follows a precise heating program to fire, or vitrify, the porcelain. This process hardens the material, creates a glaze for a natural appearance, and bonds the porcelain to its substructure.

Function 2: Pressing Ingot-Based Ceramics

This function is what makes a combination furnace unique. It adds the element of pressure to the heating process, allowing the fabrication of monolithic restorations from ceramic ingots (e.g., lithium disilicate).

The technician first creates a wax pattern of the final restoration. This wax-up is then invested in a specialized ring. A ceramic ingot is placed in the ring, which is then put into the furnace. The furnace heats the ingot until it becomes plasticized and then uses pneumatic or mechanical pressure to press the molten ceramic into the void left by the burned-out wax pattern.

Why This Versatility Matters for the Modern Lab

The ability to both fire and press ceramics in one machine has significant strategic advantages for a dental laboratory.

Expanding Material Capabilities

A lab with a combination furnace is not limited to a single ceramic system. It can efficiently produce both highly aesthetic layered restorations and strong, monolithic pressed restorations. This allows the lab to meet the specific clinical and aesthetic demands of any case.

Optimizing Workflow and Space

The most obvious benefit is efficiency. Instead of purchasing, housing, and maintaining two separate machines—a press furnace and a firing furnace—a lab can accomplish both tasks with one. This saves valuable bench space and reduces the initial capital investment.

Ensuring Precise, Aesthetic Results

Modern combination furnaces offer precise control over temperature, heating rates, and pressure. They come with pre-set programs for a wide variety of ceramic materials and can be customized. This level of control is crucial for achieving consistent, high-strength restorations with accurate shades and lifelike aesthetics.

Understanding the Trade-offs: Combination vs. Specialized Furnaces

While incredibly versatile, a combination furnace is not a one-size-fits-all solution for every dental fabrication process. Understanding its limitations is key to making an informed decision.

The Critical Distinction: Not a Sintering Furnace

A ceramic combination furnace cannot sinter zirconia. This is the most common point of confusion. Sintering is a different process that requires much higher temperatures (typically 1450°C to 1550°C) to transform a milled zirconia framework from its chalky pre-sintered state into a dense, high-strength final restoration.

Labs that work with zirconia require a separate, dedicated sintering furnace. A combination furnace operates at the lower temperatures required for firing and pressing porcelain and glass-ceramics.

Potential Workflow Bottlenecks

Because a single machine performs two functions, a high-volume lab may experience bottlenecks. You cannot fire a set of layered crowns and press a lithium disilicate crown at the same time. A lab with very high output in both categories might find that dedicated, separate machines for firing and pressing offer better throughput.

Making the Right Choice for Your Lab

Your decision should be driven by the types of restorations your lab produces most frequently.

- If your primary focus is maximum versatility and space efficiency: A combination furnace is the ideal choice for labs that want to offer both layered and pressed ceramic restorations without investing in multiple large devices.

- If your primary focus is high-volume zirconia production: A combination furnace is the wrong tool; you must invest in a dedicated high-temperature sintering furnace.

- If your primary focus is exclusively on layered PFM or feldspathic veneers: A simpler, firing-only ceramic furnace may be a more cost-effective solution if you have no plans to offer pressed ceramics.

Ultimately, understanding this distinction empowers you to invest in the precise technology that aligns with your lab's specific material workflow and business goals.

Summary Table:

| Function | Process | Key Applications |

|---|---|---|

| Firing Conventional Ceramics | Heating layers to vitrify porcelain | PFM crowns, layered all-ceramic restorations |

| Pressing Ingot-Based Ceramics | Applying pressure to molten ceramic ingots | Monolithic restorations (e.g., lithium disilicate crowns, inlays) |

Ready to elevate your dental lab's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for diverse laboratory needs. Leveraging exceptional R&D and in-house manufacturing, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization to precisely meet your unique experimental requirements. Whether you need versatile combination furnaces or specialized sintering units, we ensure optimal performance and efficiency. Contact us today to discuss how we can support your lab's growth and success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency