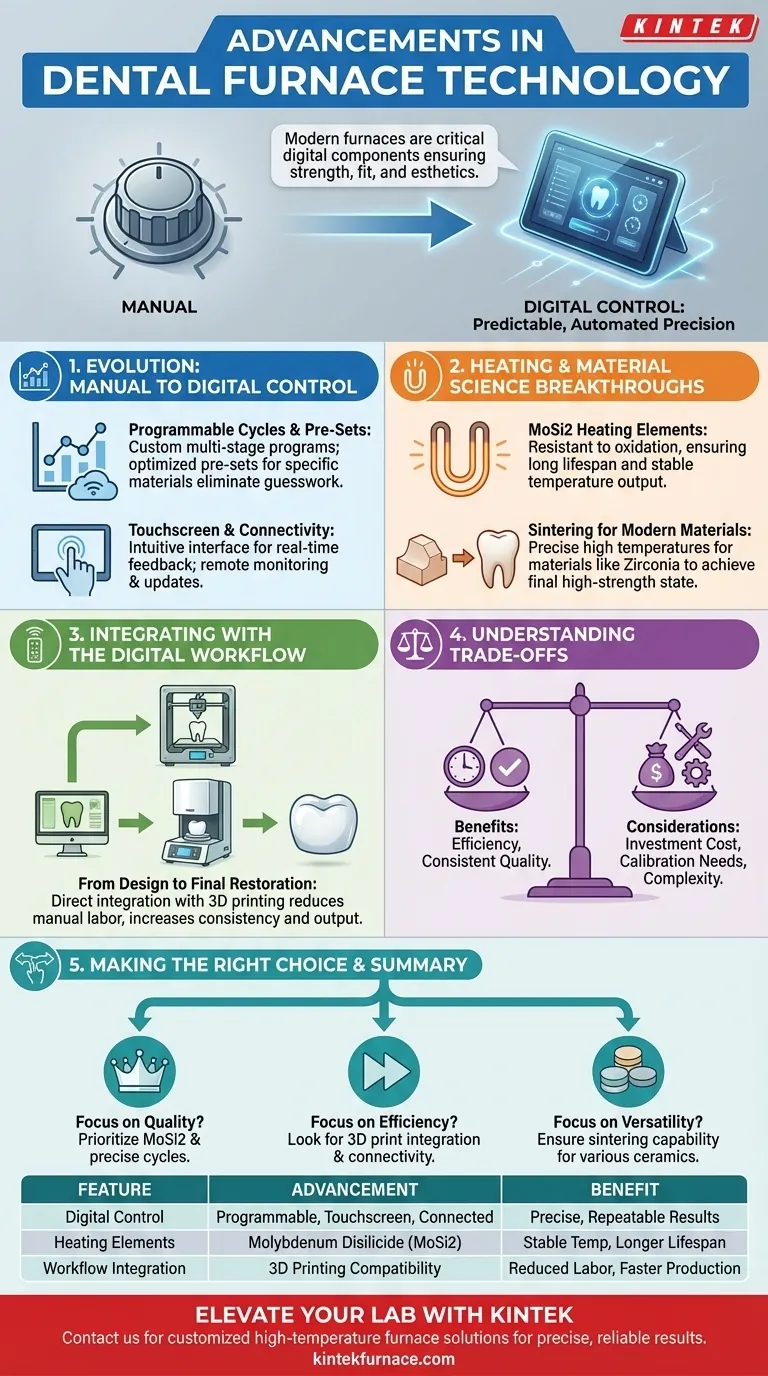

In recent years, dental furnace technology has evolved from simple heating devices into sophisticated, digitally-controlled systems. Key advancements include precise programmable firing cycles, advanced heating elements like molybdenum disilicide (MoSi2), intuitive touchscreen controls, and direct integration with digital workflows like 3D printing. These changes allow for greater accuracy, broader material compatibility, and improved efficiency in producing dental restorations.

The core advancement in dental furnaces is the shift towards predictable, automated precision. Modern furnaces are no longer just ovens; they are critical digital components that ensure the strength, fit, and esthetics of advanced ceramic restorations while streamlining the entire lab workflow.

The Evolution from Manual to Digital Control

The most significant change in dental furnace technology is the move from analog controls to sophisticated digital management. This grants dental technicians unprecedented levels of precision and repeatability.

Programmable Cycles and Pre-Set Programs

Modern furnaces feature programmable firing cycles. This allows technicians to create and save custom multi-stage programs for temperature, time, and vacuum levels.

Many units also come with pre-set programs optimized by manufacturers for specific ceramic materials, including pressable glass ceramics. This removes guesswork and ensures that restorations are fired according to exact material specifications, which is critical for achieving desired strength and translucency.

Touchscreen Interfaces and Connectivity

Clunky buttons have been replaced by intuitive touchscreen controls. This simplifies programming and provides real-time feedback on the firing cycle.

Furthermore, internet connectivity enables remote monitoring, cycle-data logging for quality control, and simplified software updates from the manufacturer, ensuring the furnace remains compatible with new materials.

Breakthroughs in Heating and Material Science

Advancements are not limited to the control interface. The core heating technology has also seen fundamental improvements, directly impacting restoration quality and furnace longevity.

Molybdenum Disilicide (MoSi2) Heating Elements

A key innovation is the use of molybdenum disilicide (MoSi2) heating elements. Unlike traditional elements, MoSi2 is highly resistant to oxidation at high temperatures.

This results in a much longer lifespan and, more importantly, stable temperature output over thousands of cycles. This consistency is essential for preventing under- or over-firing and achieving predictable results every time.

Sintering for Modern Materials

The rise of materials like zirconia has driven the need for furnaces capable of sintering. This process requires extremely high, accurately controlled temperatures to shrink and densify the milled material into its final, high-strength state. Modern furnaces provide the precise control needed for this demanding application.

Integrating with the Digital Dental Workflow

Today's dental furnace is a key component in a fully digital production chain, connecting design software with the final physical restoration.

The Role of 3D Printing Integration

The most forward-thinking advancement is the integration with 3D printing. The workflow involves designing a restoration on a computer, printing it with a specialized material, and then placing it in the furnace for a final sintering or glazing cycle.

This digital workflow dramatically reduces the manual labor and production time associated with traditional methods, allowing labs to increase output and consistency. The furnace acts as the final, critical step that transforms a printed object into a durable, clinically-ready restoration.

Understanding the Trade-offs

While modern furnaces offer significant advantages, it is important to approach them with a clear understanding of their requirements.

Cost of Investment

Technologically advanced furnaces represent a significant capital investment compared to older, simpler models. The long-term benefits of efficiency and quality must be weighed against the initial upfront cost.

Calibration and Maintenance

Precision requires diligence. To ensure the accuracy that these furnaces promise, they require regular temperature calibration. Without proper maintenance, even the most advanced furnace can produce inconsistent results, compromising the quality of restorations.

Increased Complexity

Features like network connectivity and complex programming, while powerful, introduce a higher level of technical complexity. Staff must be properly trained to leverage these features effectively and troubleshoot potential issues.

Making the Right Choice for Your Goal

Selecting a furnace should be driven by the specific needs and goals of your practice or laboratory.

- If your primary focus is consistent restoration quality: Prioritize a furnace with MoSi2 heating elements and precise, easily programmable firing cycles for predictable outcomes.

- If your primary focus is workflow efficiency: Look for models with 3D printing integration, pre-set programs for your most-used materials, and remote connectivity features.

- If your primary focus is material versatility: Ensure the furnace is designed for both firing traditional porcelains and sintering modern ceramics like zirconia.

Ultimately, investing in the right furnace technology empowers you to deliver higher-quality restorations with greater efficiency and predictability.

Summary Table:

| Advancement | Key Features | Benefits |

|---|---|---|

| Digital Control | Programmable cycles, touchscreen interfaces, connectivity | Precise, repeatable results; simplified operation |

| Heating Elements | Molybdenum disilicide (MoSi2) | Longer lifespan, stable temperature, consistent outcomes |

| Workflow Integration | 3D printing compatibility, pre-set programs | Reduced labor, faster production, enhanced consistency |

Ready to elevate your dental lab with cutting-edge furnace solutions? Contact KINTEK today to discover how our advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, can be customized to meet your unique needs. Leverage our exceptional R&D and in-house manufacturing for precise, efficient, and reliable results that enhance your restoration quality and workflow efficiency.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations