At their core, vertical tube furnaces are indispensable tools in any field requiring precise thermal processing of materials within a tightly controlled atmosphere. They are most prominently used in materials science, nanotechnology, electronics, and chemical processing, but their applications extend to metallurgy, new energy research, and environmental science. The furnace's design is not just about heating; it's about creating a perfect, isolated environment for transformative chemical and physical reactions.

The defining value of a vertical tube furnace lies in its ability to create a highly uniform and controllable environment. This makes it essential for advanced processes like chemical vapor deposition (CVD), annealing, and material synthesis, where atmospheric purity and temperature precision directly determine the quality of the final product.

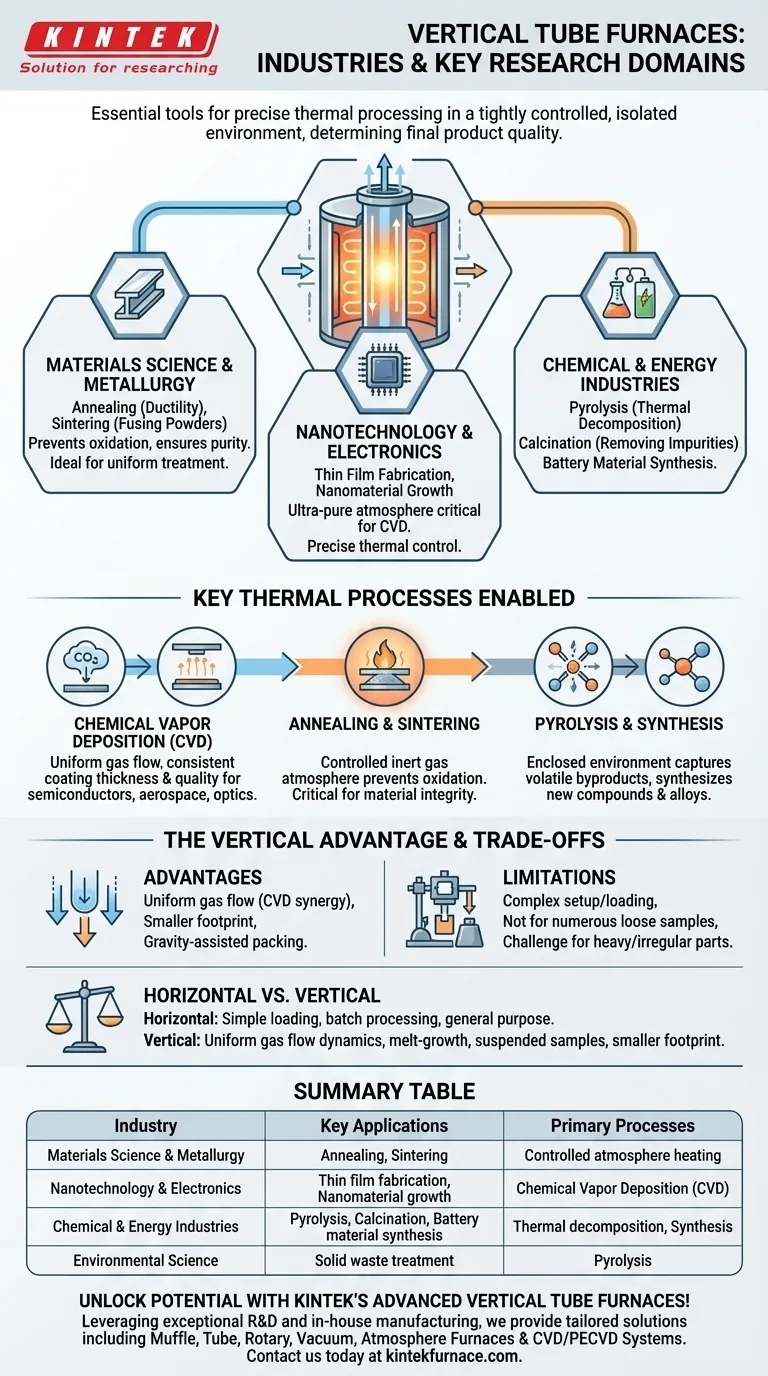

Core Applications Across Key Sectors

The utility of a vertical tube furnace is defined by the specific processes it enables. Different industries leverage its unique capabilities for distinct goals.

Materials Science and Metallurgy

In materials research, a furnace is a primary tool for manipulating the fundamental properties of a substance. Processes like annealing (heat-treating to increase ductility and reduce hardness) and sintering (using heat to fuse powders into a solid mass) require immaculate atmospheric control to prevent oxidation and ensure material purity. The vertical orientation can be advantageous for uniform heat treatment of suspended samples or powders.

Nanotechnology and Electronics

These fields demand the highest level of precision. Vertical tube furnaces are fundamental for fabricating nanostructures and semiconductor components. The ability to maintain an ultra-pure atmosphere is critical, as even minute contaminants can ruin a microelectronic device. The furnace's precise thermal control allows for the controlled growth of thin films and nanomaterials.

Chemical and Energy Industries

For chemists and energy researchers, the furnace is a miniature reactor. It is widely used for pyrolysis (thermal decomposition in an inert atmosphere) and calcination (heating to remove impurities or water). In the energy sector, these furnaces are critical for synthesizing and testing new materials for lithium-ion batteries and other next-generation energy systems.

Key Thermal Processes Enabled by a Vertical Furnace

The "why" behind the furnace's adoption is its suitability for several high-value thermal processes that are difficult or impossible to achieve in an open-air environment.

Chemical Vapor Deposition (CVD)

CVD is a cornerstone process for creating high-quality, high-performance thin films and coatings used in semiconductors, aerospace, and optics. Precursor gases react and decompose on a heated substrate inside the furnace, depositing a solid film. The vertical tube design facilitates a uniform flow of gas over the substrate, leading to highly consistent coating thickness and quality.

Annealing and Sintering

Annealing metals or sintering ceramic powders requires holding a material at a specific temperature for a set time. The tube furnace's ability to be purged with an inert gas like argon or nitrogen is essential. This controlled atmosphere prevents the material from reacting with oxygen at high temperatures, which would otherwise compromise its structural integrity.

Pyrolysis and Synthesis

Pyrolysis is used to break down organic materials, such as in solid waste treatment or creating specialized carbon materials. The enclosed tube contains the process, allowing for the safe capture of volatile byproducts. Similarly, it provides the ideal sealed environment for synthesizing new chemical compounds and alloys from raw materials.

Understanding the Trade-offs

While powerful, a vertical tube furnace is a specialized tool. Understanding its specific advantages and limitations is key to using it effectively.

The Vertical Advantage

The primary advantage of the vertical orientation is its synergy with gravity and gas flow. For CVD, a top-down gas flow can ensure uniform deposition. For certain crystal growth techniques or processes involving powders, gravity helps ensure consistent packing and heating. Additionally, a vertical furnace often has a smaller footprint, saving valuable lab space.

Comparison to Horizontal Furnaces

Horizontal tube furnaces are often simpler to load and unload, especially for batch processing multiple small samples placed in a ceramic boat. They are a workhorse for general-purpose heat treatment. A vertical furnace is typically chosen when the process itself benefits from the vertical orientation, such as uniform gas flow dynamics in CVD, melt-growth applications, or when a sample must be suspended.

Key Limitations

Vertical furnaces can be more complex to set up, particularly for loading and securing samples. They may not be suitable for processing numerous small, loose samples simultaneously, a task better suited for a horizontal configuration. Very heavy or irregularly shaped parts that cannot be easily suspended or supported may also pose a challenge.

Making the Right Choice for Your Application

Your choice of furnace should be dictated entirely by the requirements of your process.

- If your primary focus is creating high-purity thin films or coatings: A vertical tube furnace optimized for Chemical Vapor Deposition (CVD) is essential for its precise atmospheric and thermal control.

- If your primary focus is heat-treating metals or sintering powders: A furnace with excellent temperature uniformity and a robust system for inert gas purging is critical to prevent oxidation and ensure consistent results.

- If your primary focus is general R&D and material synthesis: Prioritize a versatile system with programmable temperature controls and the flexibility of interchangeable tube diameters to accommodate a wide range of experiments.

Ultimately, selecting the correct furnace is about matching its specific environmental controls to the precise requirements of your material processing goal.

Summary Table:

| Industry/Research Domain | Key Applications | Primary Processes |

|---|---|---|

| Materials Science & Metallurgy | Annealing, Sintering | Controlled atmosphere heating |

| Nanotechnology & Electronics | Thin film fabrication, Nanomaterial growth | Chemical Vapor Deposition (CVD) |

| Chemical & Energy Industries | Pyrolysis, Calcination, Battery material synthesis | Thermal decomposition, Synthesis |

| Environmental Science | Solid waste treatment | Pyrolysis |

Unlock the full potential of your thermal processing with KINTEK's advanced vertical tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether in materials science, electronics, or energy research. Contact us today to discuss how our high-temperature furnace solutions can enhance your research efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab