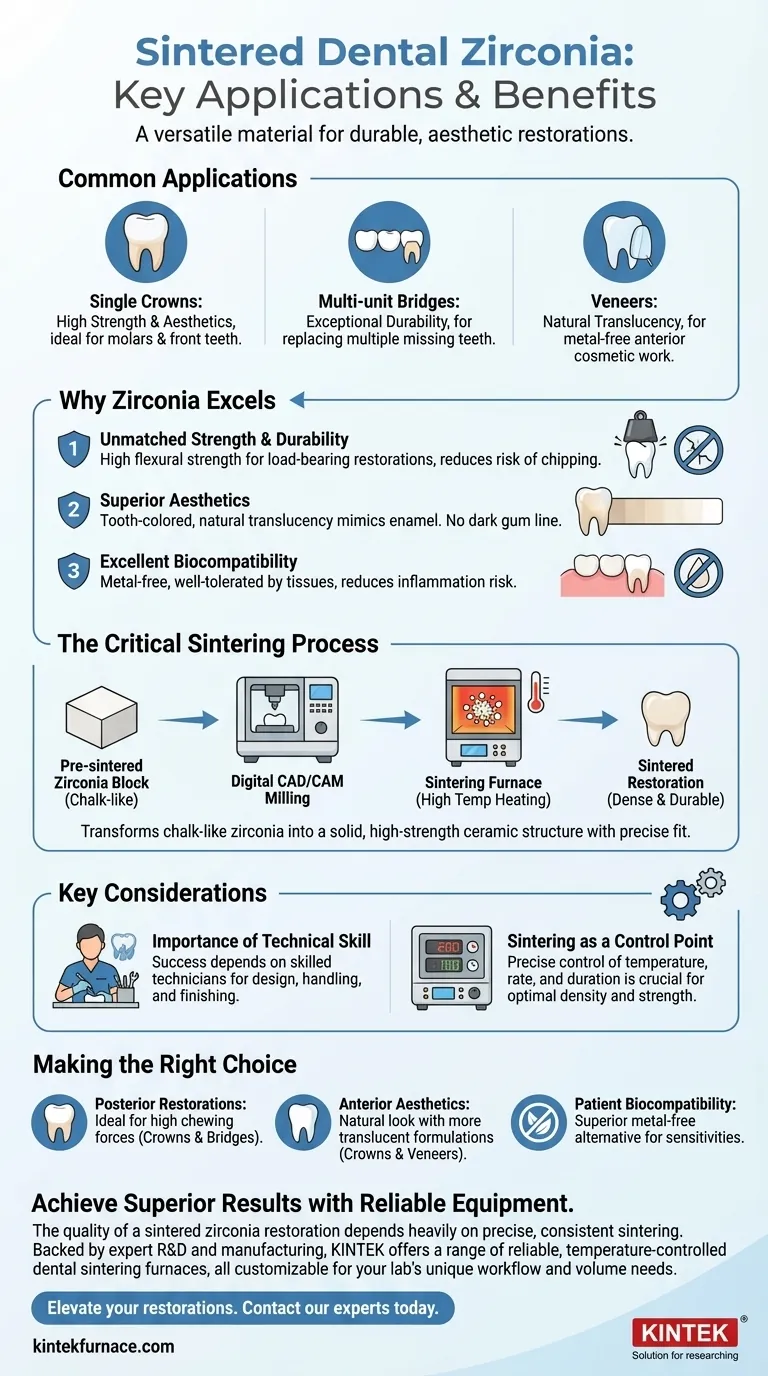

In modern restorative dentistry, sintered zirconia is a highly versatile material used for fabricating a range of durable and aesthetic dental prosthetics. Its most common applications include full-ceramic single crowns, multi-unit bridges, and cosmetic veneers, where it replaces traditional metal-based restorations.

Sintered zirconia has become a preferred material not just for what it creates, but for how it combines exceptional strength for load-bearing restorations with the biocompatibility and natural appearance required for a successful, long-term clinical outcome.

Why Zirconia Excels in These Applications

The widespread adoption of sintered zirconia is due to a unique combination of physical and aesthetic properties that make it suitable for challenging restorative cases. It solves many of the problems associated with older materials.

Unmatched Strength and Durability

Sintered zirconia exhibits remarkable flexural strength, far exceeding that of many other dental ceramics. This makes it an ideal choice for restorations in high-stress areas, such as molar crowns and long-span bridges that must withstand significant chewing forces.

This inherent toughness reduces the risk of fractures or chipping that can occur with weaker ceramic materials, contributing to the longevity of the restoration.

Superior Aesthetics

Unlike metal-based restorations that can create a dark line at the gum, zirconia is a tooth-colored material. Modern formulations offer varying levels of translucency, allowing them to mimic the appearance of natural enamel.

This makes zirconia an excellent material for anterior (front tooth) crowns and veneers, where achieving a seamless, natural look is the highest priority.

Excellent Biocompatibility

Zirconia is a ceramic and contains no metal, making it an ideal solution for patients with known metal allergies or sensitivities. Its biocompatible nature means it is well-tolerated by the surrounding gum tissues, reducing the risk of inflammation or allergic reactions.

The Critical Role of the Sintering Process

Zirconia does not start as a strong material. The sintering process is the essential manufacturing step that transforms it into its final, dense, and durable state, making it suitable for clinical use.

Transforming the Material

Dental restorations are first milled from a chalk-like block of pre-sintered zirconia using a digital CAD/CAM system. This soft state allows for precise and easy shaping.

The restoration is then placed in a specialized furnace and heated to very high temperatures. This sintering process causes the zirconia particles to fuse, shrinking the restoration by about 20-25% and transforming it into a solid, high-strength ceramic structure.

Precision Through Digital Workflows

The entire process is digitally controlled. From the initial intraoral scan to the final milling, digital equipment ensures an incredibly precise fit for the final crown, bridge, or veneer.

This precision is critical for patient comfort, proper function, and the long-term health of the underlying tooth.

Understanding the Key Considerations

While sintered zirconia offers significant benefits, the quality of the final outcome is not automatic. It depends heavily on the equipment used and the skill of the professional managing the process.

The Importance of Technical Skill

The success of a zirconia restoration is highly dependent on the competence of the dental technician. Proper design, handling, and finishing are crucial for both strength and aesthetics.

Choosing a dental laboratory that invests in skilled technicians and top-tier equipment is essential for achieving predictable, high-quality results.

Sintering is a Critical Control Point

The sintering cycle itself—including the precise temperature, heating rate, and duration—must be carefully controlled. Improper sintering can introduce internal stresses or prevent the material from reaching its optimal density, leading to premature failure.

Reliable, temperature-controlled furnaces are necessary to ensure thorough and consistent sintering, which is the foundation of the restoration's strength.

Making the Right Choice for Your Goal

Sintered zirconia is not a one-size-fits-all solution, but its versatility makes it a leading choice for many common restorative needs.

- If your primary focus is posterior restorations (molars): Zirconia's high strength makes it the ideal choice for crowns and bridges that must withstand significant chewing forces.

- If your primary focus is anterior aesthetics (front teeth): More translucent zirconia formulations are excellent for crowns and veneers, offering a natural look without the risk of a dark metal line at the gum.

- If your primary focus is patient biocompatibility: Zirconia is a superior metal-free alternative for patients with known metal allergies or sensitivities.

Ultimately, understanding zirconia's properties allows clinicians to leverage its strength and beauty for predictable, long-lasting patient outcomes.

Summary Table:

| Application | Key Benefit | Ideal For |

|---|---|---|

| Single Crowns | High Strength & Aesthetics | Molars and Front Teeth |

| Multi-unit Bridges | Exceptional Durability | Replacing Multiple Missing Teeth |

| Veneers | Natural Translucency | Metal-Free Anterior Cosmetic Work |

Ready to achieve superior strength and aesthetics in your dental lab?

The quality of a sintered zirconia restoration depends heavily on precise, consistent sintering. Backed by expert R&D and manufacturing, KINTEK offers a range of reliable, temperature-controlled dental sintering furnaces, all customizable for your lab's unique workflow and volume needs.

Elevate your restorations with equipment you can trust. Contact our experts today to find the perfect sintering solution for your practice.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns