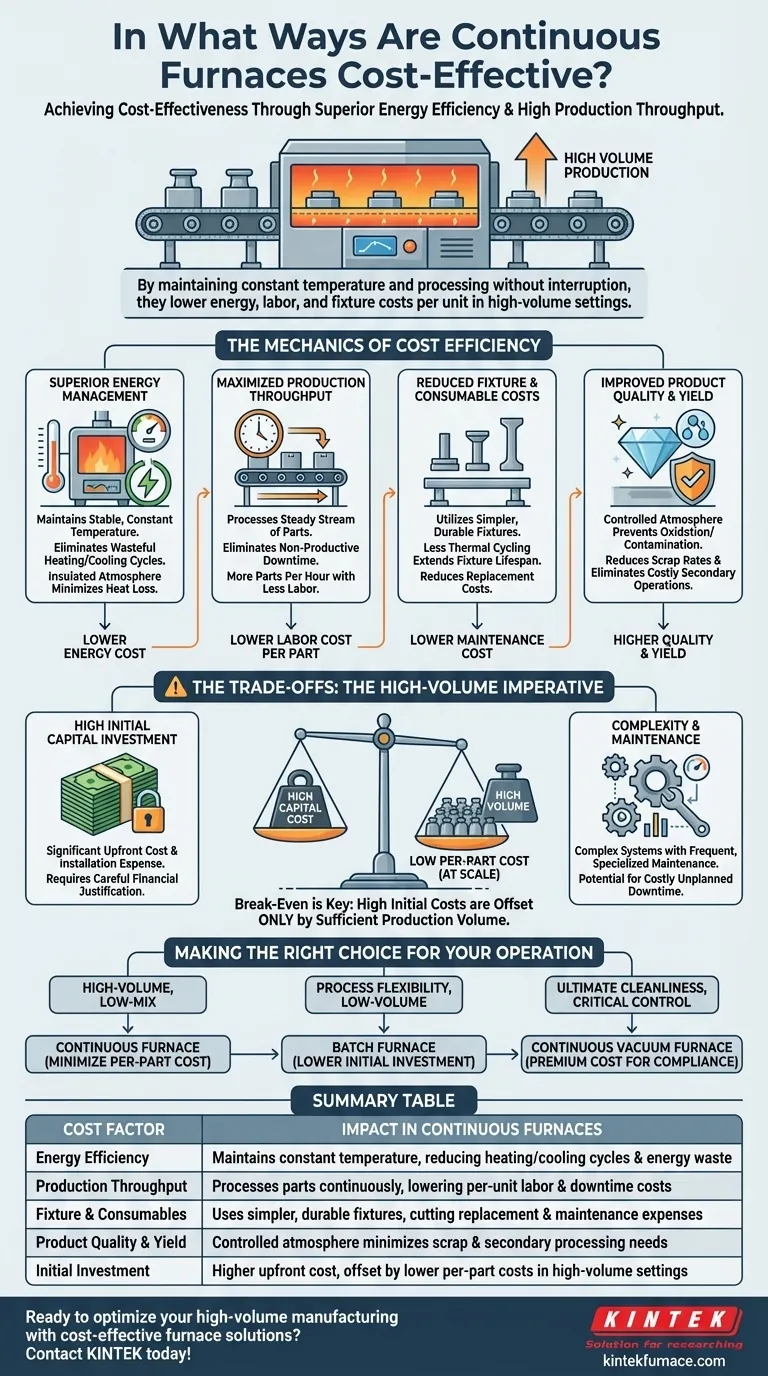

In short, continuous furnaces achieve cost-effectiveness through superior energy efficiency and high production throughput. By maintaining a constant operating temperature, they eliminate the wasteful energy cycles of heating and cooling common in batch furnaces. This, combined with their ability to process parts without interruption, dramatically lowers the energy, labor, and fixture cost for each unit produced in a high-volume setting.

The true cost-effectiveness of a continuous furnace is unlocked at scale. While the initial investment is significant, the substantial reduction in per-part operating costs provides a powerful economic advantage for high-volume, consistent manufacturing operations.

The Mechanics of Cost Efficiency

To understand if a continuous furnace is right for you, it's essential to look beyond the price tag and analyze the specific mechanisms that drive its long-term value.

Superior Energy Management

A primary cost driver in any thermal process is energy. Continuous furnaces are designed for optimal energy conservation by maintaining a stable, constant temperature in their heating zones.

This avoids the massive energy expenditure required to repeatedly heat a batch furnace from a low temperature to its operating point for every new load. Furthermore, the controlled atmosphere systems used in many continuous furnaces act as an insulator, minimizing ambient heat loss.

Maximized Production Throughput

Time is a critical cost component in manufacturing. Continuous furnaces excel by processing a steady stream of parts with minimal interruption, effectively eliminating non-productive downtime between loads.

This high throughput means more parts can be produced per hour with the same or less labor compared to a batch process. The result is a significantly lower labor cost allocated to each individual part.

Reduced Fixture and Consumable Costs

Because the process is highly consistent and parts move uniformly, continuous furnaces can often utilize simpler, more durable, and less expensive fixtures.

In contrast, batch furnaces may require complex, heavy, and costly fixtures designed to hold diverse loads and withstand severe thermal cycling, which shortens their lifespan and increases replacement costs.

Improved Product Quality and Yield

The highly controlled atmosphere (often using inert gases) inside a continuous furnace prevents oxidation and contamination during the heating process.

This leads directly to higher product quality and a reduction in scrap rates. It can also eliminate the need for costly and time-consuming secondary operations like acid pickling or abrasive cleaning, further reducing the total cost of production.

Understanding the Trade-offs: The High-Volume Imperative

The economic benefits of a continuous furnace are substantial, but they are not universal. Failing to understand the trade-offs is the most common reason for a poor investment decision.

High Initial Capital Investment

The most significant barrier is cost. Continuous furnaces are complex systems that are considerably more expensive to purchase and install than their batch-style counterparts. This high capital expenditure requires careful financial justification.

Complexity and Maintenance Costs

These are not simple machines. Their continuous operation relies on a complex system of conveyors, sensors, and automated controls. They demand more frequent and specialized maintenance to ensure reliability and prevent costly unplanned downtime.

The Break-Even Point: Volume is Key

The core principle is this: the high initial and maintenance costs are offset by a very low per-part cost. This model only works if you have sufficient production volume.

For a low-volume or high-mix, low-volume (HMLV) job shop, a continuous furnace would likely sit idle much of the time, making it impossible to recoup the initial investment. In such cases, a less expensive, more flexible batch furnace is almost always the more cost-effective choice.

Making the Right Choice for Your Operation

The decision to invest in a continuous furnace must be driven by a clear understanding of your specific production goals and constraints.

- If your primary focus is high-volume, low-mix manufacturing: A continuous furnace is the definitive choice for minimizing your per-part production cost.

- If your primary focus is process flexibility or producing varied, low-volume parts: A batch furnace offers a lower initial investment and is far more cost-effective for your operational model.

- If your primary focus is ultimate product cleanliness and environmental control: A continuous vacuum furnace justifies its premium cost by preventing contamination and ensuring compliance in critical industries.

Ultimately, choosing the right furnace technology is a strategic decision that hinges on aligning the equipment's strengths with your production volume and business objectives.

Summary Table:

| Cost Factor | Impact in Continuous Furnaces |

|---|---|

| Energy Efficiency | Maintains constant temperature, reducing heating/cooling cycles and energy waste |

| Production Throughput | Processes parts continuously, lowering per-unit labor and downtime costs |

| Fixture and Consumables | Uses simpler, durable fixtures, cutting replacement and maintenance expenses |

| Product Quality and Yield | Controlled atmosphere minimizes scrap and secondary processing needs |

| Initial Investment | Higher upfront cost, offset by lower per-part costs in high-volume settings |

Ready to optimize your high-volume manufacturing with cost-effective furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Contact us today to discuss how our solutions can enhance your efficiency and reduce costs!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening