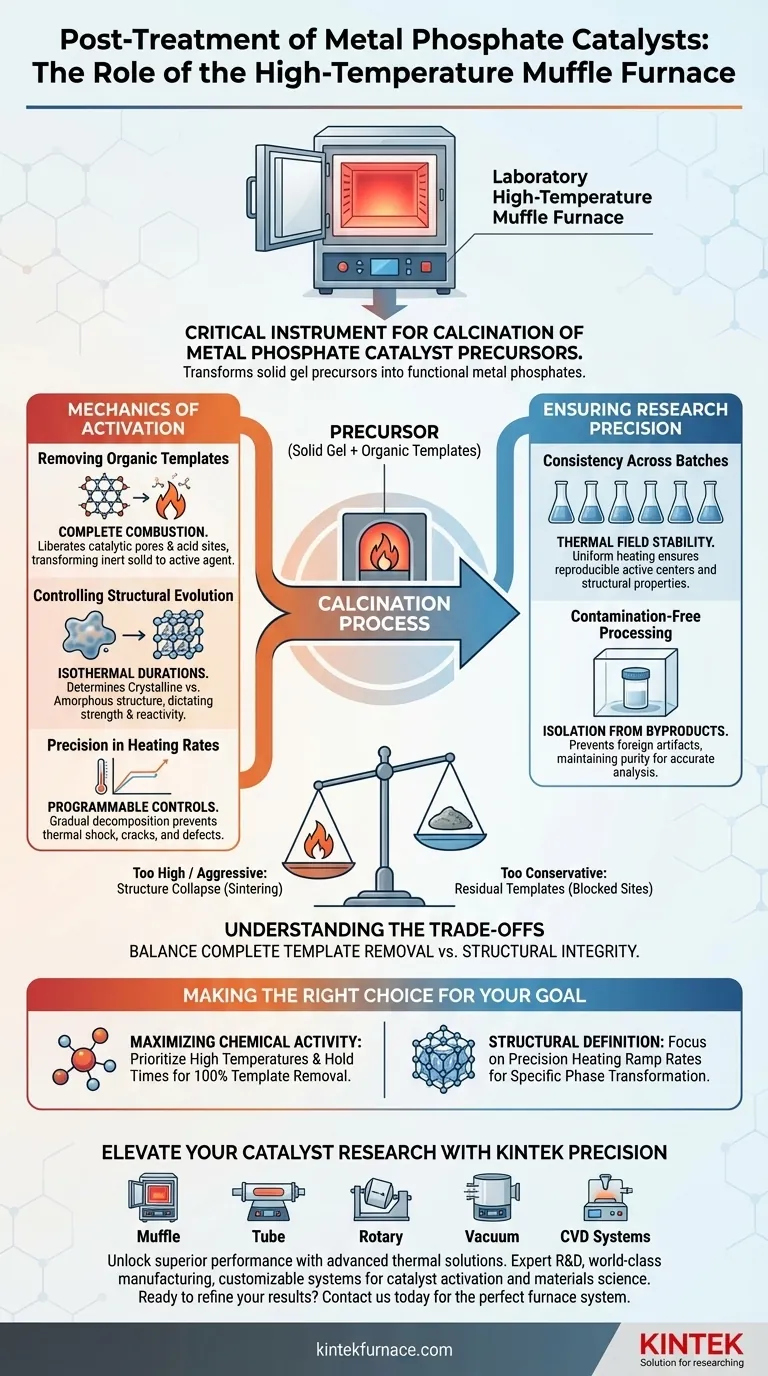

The laboratory high-temperature muffle furnace serves as the critical instrument for the calcination of metal phosphate catalyst precursors. It allows for the precise thermal treatment required to transform solid gel precursors into functional metal phosphates. This process is essential for removing organic templates and establishing the necessary crystalline or amorphous architecture.

Core Takeaway: The muffle furnace is not merely a heating device; it is a structural tool. Its primary value lies in "liberating" the catalyst's active sites by burning off synthesis templates and enforcing the specific thermal history required to stabilize the catalyst's final physical form.

The Mechanics of Activation

Removing Organic Templates

During the synthesis of metal phosphates, organic template agents are often used to shape the material. These agents must be removed to make the catalyst functional.

The high-temperature environment of the muffle furnace ensures the complete combustion and removal of these organic organics. This process liberates the catalytic pores and acid sites, transforming the material from an inert solid into an active chemical agent.

Controlling Structural Evolution

The transition from a raw precursor to a finished catalyst is complex. The muffle furnace facilitates the transformation of solid gel precursors into defined metal phosphates.

By adhering to specific isothermal durations (holding times), the furnace allows the material to settle into the correct phase. This control determines whether the final product exhibits a crystalline or amorphous structure, which directly dictates its physical strength and reactivity.

Precision in Heating Rates

The speed at which temperature rises is just as important as the final temperature reached. The muffle furnace offers programmable digital controls to regulate heating rates.

Controlled heating decomposes metal salt precursors into active oxides without shocking the material. This gradual evolution helps form the initial skeletal structure of the catalyst without inducing cracks or defects.

Ensuring Research Precision

Consistency Across Batches

In a laboratory setting, reproducibility is paramount. The muffle furnace is valued for its excellent thermal field stability.

This uniform heating ensures that every batch of catalyst experiences the exact same thermal conditions. Consequently, the resulting active centers and structural properties remain consistent from one experiment to the next.

Contamination-Free Processing

High-performance catalysts are sensitive to impurities. Muffle furnaces are designed to isolate the sample from fuel combustion byproducts or external contaminants.

This isolation is critical when conducting scientific research or analyzing composition. It ensures that the catalytic activity observed is inherent to the material design, not a result of foreign artifacts introduced during heating.

Understanding the Trade-offs

While the muffle furnace is essential, improper use can degrade catalyst performance. The trade-off lies in the balance between complete template removal and structural integrity.

If the temperature is too high or the heating rate too aggressive, you risk collapsing the pore structure (sintering) or altering the crystalline phase beyond the desired state. Conversely, being too conservative with heat will leave residual organic templates, effectively blocking the active sites and rendering the catalyst useless.

Making the Right Choice for Your Goal

To maximize the effectiveness of your post-treatment, align your furnace settings with your specific objectives:

- If your primary focus is Maximizing Chemical Activity: Prioritize high temperatures and sufficient hold times to ensure 100% removal of organic templates and full liberation of acid sites.

- If your primary focus is Structural Definition: Focus on the precision of your heating ramp rates to carefully guide the transformation from gel to the specific crystalline or amorphous phase required.

The muffle furnace is the gatekeeper that determines whether your precursor becomes a high-performance catalyst or remains an inert solid.

Summary Table:

| Process Function | Impact on Catalyst | Key Benefit |

|---|---|---|

| Organic Template Removal | Liberates pores and acid sites | Transforms inert precursors into active agents |

| Structural Evolution | Controls crystalline vs. amorphous phase | Determines physical strength and reactivity |

| Programmable Heating | Gradual decomposition of metal salts | Prevents structural cracks and thermal defects |

| Thermal Field Stability | Uniform batch processing | Ensures experimental reproducibility and consistency |

| Sample Isolation | Prevention of external contamination | Maintains purity of catalytic active centers |

Elevate Your Catalyst Research with KINTEK Precision

Unlock superior performance in your laboratory with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored specifically for the rigorous demands of catalyst activation and materials science.

Whether you need to optimize organic template removal or master complex structural evolution, our customizable high-temperature furnaces deliver the thermal stability and programmable precision your research requires.

Ready to refine your results? Contact us today to discover how KINTEK can design the perfect furnace system for your unique laboratory needs.

Visual Guide

References

- A. Garcia, Salvador Ordóñez. Sustainable Production of Jet Fuel Additives Through Acetone Self‐Condensation Catalyzed by Metal Phosphates. DOI: 10.1002/cctc.202500449

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What temperature range can a standard muffle furnace achieve? Find Your Ideal Heat Range

- Why is precise temperature control important in crucible furnaces? Ensure Quality & Efficiency in Thermal Processing

- How does the feeding and discharging device contribute to the operation of a box furnace? Enhance Safety and Process Control

- How does a laboratory muffle furnace contribute to the transformation of biomass into carbon precursors? Expert Guide

- How is temperature controlled in a box type electric furnace? Master Precise Heat Regulation for Your Lab

- How does the furnace wall and roof of a box type resistance furnace transfer heat to the metal? Discover the Key Mechanism for Uniform Heating

- How is the temperature controlled in a muffle furnace? Master Precise Heating for Your Lab

- What processes can be performed using box furnaces? Unlock Versatile Thermal Solutions for Your Lab