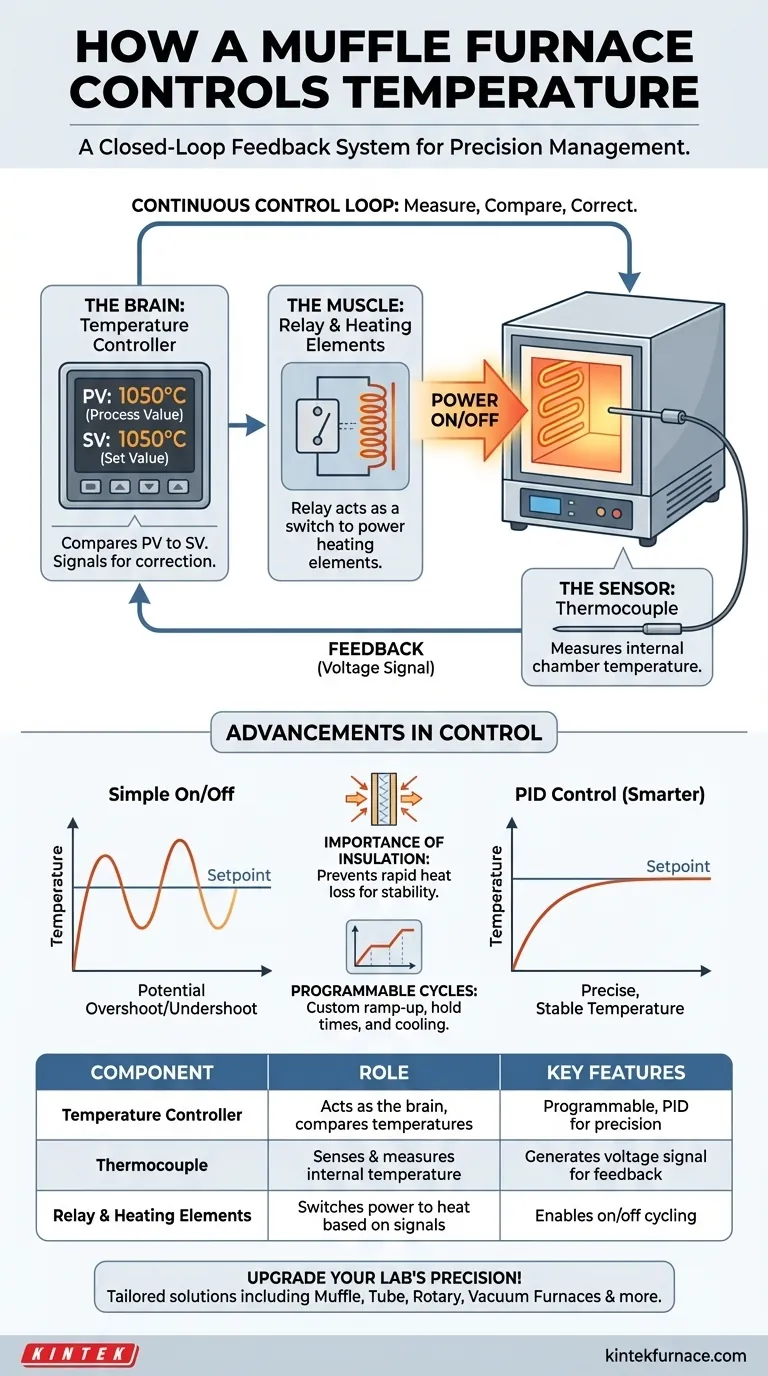

In short, a muffle furnace controls its temperature using a closed-loop feedback system. This system consists of a temperature controller that acts as the brain, a thermocouple that serves as the sensor, and an electromagnetic relay that functions as a switch to turn the heating elements on and off.

A muffle furnace doesn't simply produce heat; it precisely manages it. Temperature control is achieved through a continuous cycle of measurement, comparison, and correction, ensuring the internal chamber temperature consistently matches the user-defined setpoint.

The Core Components of Temperature Control

To understand how the furnace achieves such stable temperatures, it's essential to look at the three key components working in unison.

The Brain: The Temperature Controller

The temperature controller is the central decision-making unit. It displays two critical values: the Process Value (PV), which is the current temperature inside the furnace, and the Set Value (SV), which is the target temperature you have programmed.

Modern furnaces feature programmable controllers. These allow you to define complex heating cycles, including specific ramp-up rates (how fast to heat), hold times (how long to stay at a temperature), and cooling periods.

The Sensor: The Thermocouple

The thermocouple is a robust sensor placed inside the furnace chamber to measure the actual temperature. It works by generating a tiny voltage that changes predictably with temperature.

This voltage signal is sent back to the temperature controller, providing the real-time feedback (the PV) that is essential for the system to make adjustments.

The Muscle: The Relay and Heating Elements

The electromagnetic relay is an electronically operated switch. Based on signals from the controller, the relay opens or closes, controlling the flow of high-power electricity to the furnace's heating elements.

When the relay is closed, the elements receive power and generate heat. When it's open, the power is cut, and the elements stop heating.

How the System Works: The Control Loop in Action

These components operate in a continuous, automatic feedback loop to maintain the target temperature.

Setting the Target

The process begins when the user enters a Set Value (SV) into the temperature controller.

Constant Measurement and Comparison

The thermocouple continuously measures the internal chamber temperature and reports it to the controller as the Process Value (PV). The controller constantly compares this PV to the user's SV.

The Correction Cycle

If the PV is lower than the SV, the controller sends a signal to the relay, telling it to close. This delivers power to the heating elements, and the furnace temperature rises.

Once the PV reaches or slightly exceeds the SV, the controller signals the relay to open, cutting power to the elements. This on-and-off cycling maintains the temperature around the setpoint with a high degree of stability.

Understanding the Advancements and Trade-offs

While the on/off cycle is a simple and effective method, modern systems offer more sophisticated control for greater precision.

Simple On/Off vs. PID Control

Basic controllers use a simple on/off logic, which can sometimes lead to temperature "overshoot" and "undershoot" around the setpoint.

More advanced furnaces use a PID (Proportional-Integral-Derivative) controller. This is a smarter algorithm that anticipates temperature changes. It can reduce power to the heating elements as the temperature approaches the setpoint, preventing overshoot and resulting in exceptionally stable and accurate temperature control.

The Importance of Insulation

The quality of the furnace's insulation is critical. High-performance insulation prevents rapid heat loss, which means the heating elements need to cycle on less frequently. This not only improves energy efficiency but also contributes to a more stable internal temperature.

Why Programmable Cycles Matter

For sensitive processes like annealing, sintering, or tempering, simply reaching a temperature isn't enough. The rate of heating and cooling can dramatically affect the final properties of the material. Programmable controllers give you precise control over this entire thermal profile, ensuring repeatable and reliable results.

Making the Right Choice for Your Application

The level of control you need is directly tied to your specific thermal process.

- If your primary focus is basic heat treatment or drying: A furnace with a simple, reliable on/off controller is often sufficient for your needs.

- If your primary focus is sensitive material processing (e.g., sintering, advanced ceramics): A programmable PID controller is essential for achieving the precision and reproducibility your work demands.

- If your primary focus is process validation and quality control: Seek out controllers with digital data logging capabilities to record and verify your heating cycles for every run.

Ultimately, understanding this control loop empowers you to select and operate a muffle furnace with confidence, ensuring precise results for your critical work.

Summary Table:

| Component | Role in Temperature Control | Key Features |

|---|---|---|

| Temperature Controller | Acts as the brain, compares setpoint to actual temperature | Programmable cycles, PID control for precision |

| Thermocouple | Senses and measures internal temperature | Generates voltage signal for feedback |

| Relay and Heating Elements | Switches power to heat elements based on controller signals | Enables on/off cycling for stability |

Upgrade your lab's precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met for superior results in processes like sintering and annealing. Contact us today to discuss how we can enhance your thermal processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production