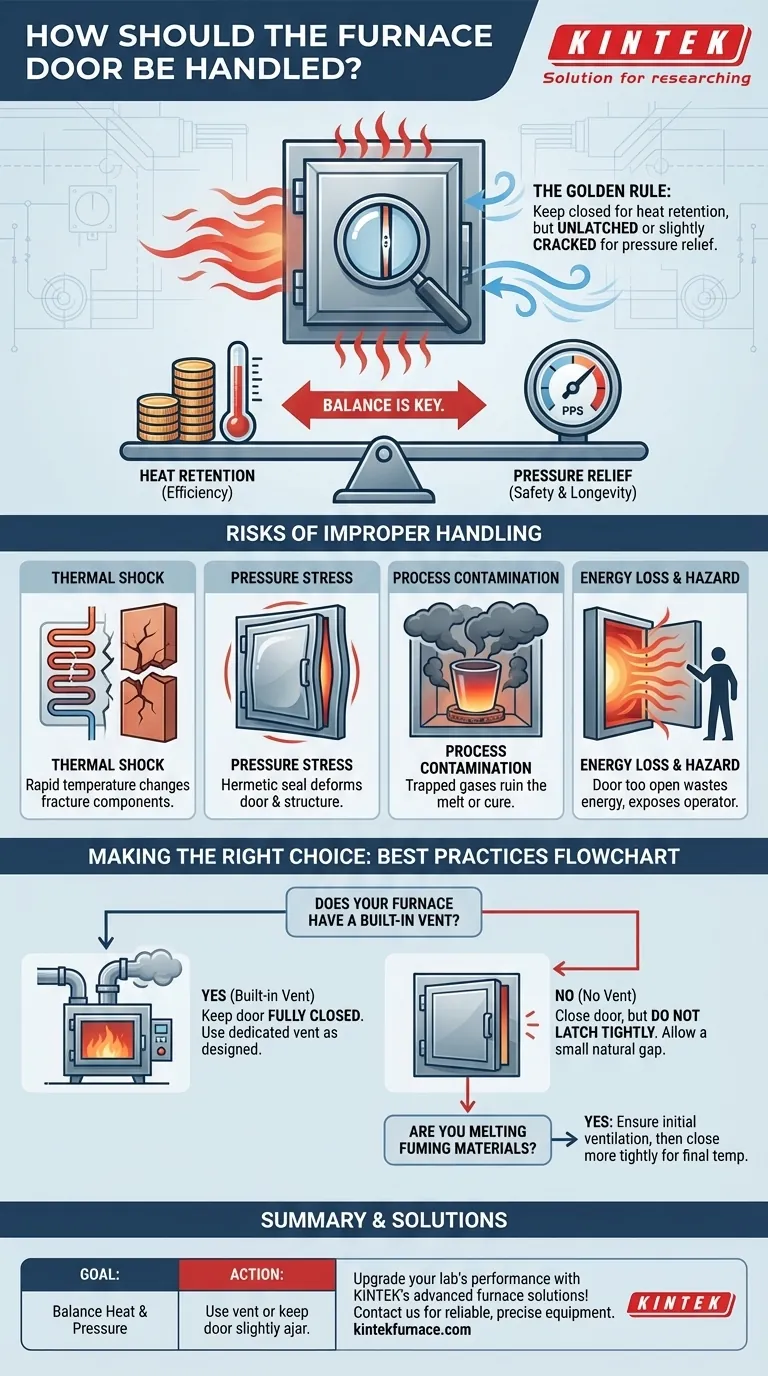

In short, your furnace door should be kept closed but not hermetically sealed during operation. It needs to be opened just enough to allow for slight ventilation. This is typically achieved by leaving it unlatched or cracked open by a very small amount, which prevents a buildup of internal pressure and allows gases to escape, protecting the furnace's internal components from damage caused by thermal shock and over-pressurization.

The core challenge in furnace operation is not simply heating, but managing pressure and thermal stress. Treating the furnace door as a simple on/off switch is a mistake; it's a control valve for maintaining a stable, safe, and efficient internal environment.

The Principle: Balancing Heat Retention and Pressure Relief

Operating a furnace effectively involves a delicate balance. You must contain enough heat for efficiency while simultaneously releasing pressure to avoid damaging the equipment.

The Need for a Closed Door

A furnace's primary job is to reach and maintain extremely high temperatures. An open door is the biggest source of heat loss, forcing the system to work harder, consume more energy, and struggle to maintain a stable target temperature. For efficiency and temperature control, the door must be kept as closed as possible.

The Danger of a Perfectly Sealed Chamber

As the air inside a furnace heats, it expands significantly. If the chamber is perfectly sealed, this creates positive pressure. This pressure pushes outwards on the furnace walls, the door, and the seals, creating physical stress that can lead to long-term damage or even immediate failure.

The Role of Off-Gassing

Many materials release gases when heated. This can be moisture turning to steam, binders in casting investments burning off, or fumes from metals. A sealed chamber traps these gases, which can contaminate the melt, create a hazardous atmosphere, or add to the internal pressure problem. A slight opening provides a necessary exhaust route.

Understanding the Risks of Improper Handling

Handling the furnace door incorrectly is not a minor issue. It directly impacts the longevity of your equipment and the quality of your work.

Risk 1: Thermal Shock Damage

Rapid temperature changes cause materials to expand or contract unevenly, leading to cracks. Keeping a door slightly ajar allows for a more gentle and controlled release of heat, preventing thermal shock that can fracture expensive components like ceramic heating elements and refractory brick or fiber lining.

Risk 2: Pressure-Induced Stress

As explained, a hermetically sealed door allows pressure to build. This constant stress can deform the furnace door, damage its seals, and weaken the overall structure of the furnace body over time.

Risk 3: Process Contamination

If gases released from your workpiece cannot escape, they can remain in the chamber. This can introduce impurities into a metal melt, affect the cure of a ceramic, or otherwise ruin the process you are trying to perform.

Risk 4: Energy Inefficiency and Safety Hazards

Leaving the door too far open is also a problem. It creates massive heat loss, wastes energy, and makes it difficult to hold a precise temperature. It also exposes the operator to intense radiant heat, posing a significant safety risk.

Making the Right Choice for Your Furnace

The correct method depends on your equipment and your specific process. Always consult your furnace's manual first, but use these principles as your guide.

- If your furnace has a built-in vent or flue: Keep the main door fully closed and use the dedicated vent to manage pressure and fumes as designed by the manufacturer.

- If your furnace lacks a dedicated vent: Close the door but do not latch it tightly, allowing a very small, natural gap for air and gas to exchange.

- If you are melting materials that produce significant fumes: Ensure the initial ventilation is adequate to allow these fumes to escape before closing the door more tightly to reach the final temperature.

Ultimately, proper furnace handling is about understanding and controlling the internal environment to protect your investment and ensure successful results.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Door Position | Keep closed but slightly ajar for ventilation |

| Purpose | Balance heat retention and pressure relief |

| Risks of Improper Use | Thermal shock, pressure damage, contamination, energy loss |

| Best Practices | Use built-in vents if available; avoid latching tightly |

Upgrade your lab's performance with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs. Contact us today to discuss how our reliable, efficient furnaces can enhance your processes and protect your investments!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance