Effective maintenance of your MPCVD's cooling water system is a systematic process centered on ensuring unobstructed water flow, maintaining system integrity, and managing water quality. This involves routinely checking components like pumps and pipes, cleaning the system to prevent clogs, inspecting all connections for leaks, and replacing the cooling water to prevent scale buildup and corrosion.

The cooling water system is not a peripheral component; it is the primary defense against thermal failure during high-power operation. Proactive maintenance is therefore a direct investment in the stability, safety, and longevity of your entire MPCVD system.

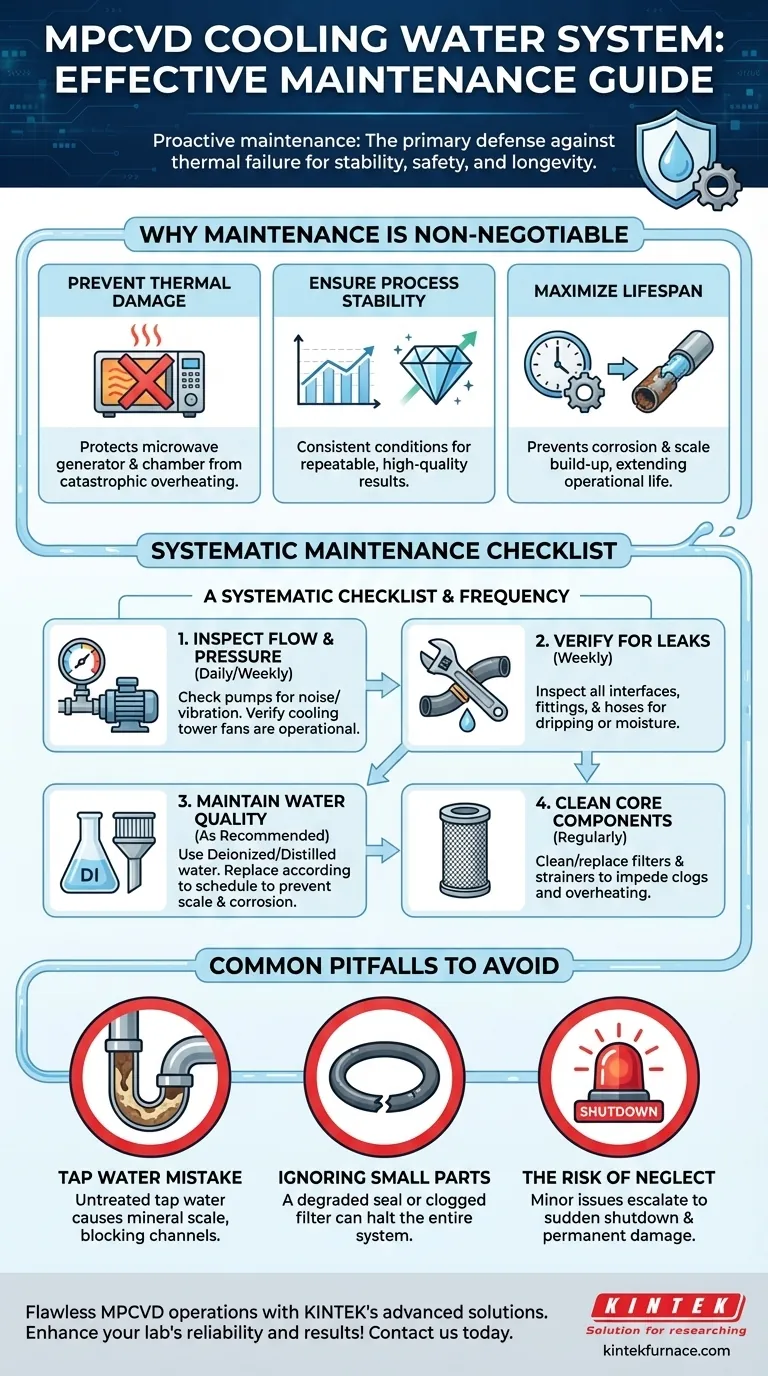

Why Cooling System Maintenance is Non-Negotiable

The cooling water circulation system is the lifeblood of your equipment, especially when operating at high power. Neglecting it introduces significant risk to your research and hardware.

Preventing Thermal Damage

MPCVD systems generate immense heat. The cooling system is the critical element that protects the microwave generator, the resonant cavity, and the substrate holder from overheating, which can cause immediate and catastrophic failure.

Ensuring Process Stability

Diamond growth and materials deposition are highly sensitive to temperature. A stable, efficient cooling system ensures consistent thermal conditions, leading to repeatable and high-quality results in your experiments and production runs.

Maximizing Equipment Lifespan

Consistent, proactive maintenance prevents the kind of cumulative damage—like corrosion or scale buildup—that shortens the operational life of expensive components. It turns a potential crisis into a predictable, manageable task.

A Systematic Maintenance Checklist

To ensure reliability, integrate these checks into a regular schedule. A formal logbook is highly recommended to track actions and observations.

1. Inspect Water Flow and Pressure

The primary function of the system is to move water. Regularly verify that it is doing so effectively. Check that water pumps are running without unusual noises or vibrations and that cooling tower fans are operational.

2. Verify System Integrity for Leaks

Water and high-power electronics are a dangerous combination. Methodically inspect all interfaces, pipe fittings, and hose connections for any signs of dripping or moisture. A small leak can reduce system pressure and cause significant damage if left unaddressed.

3. Maintain Water Quality

This is arguably the most critical long-term maintenance task. Poor water quality is the silent killer of cooling systems.

Always use the recommended grade of water (often deionized or distilled) and replace or replenish it according to the manufacturer's schedule. This single step prevents both corrosion (which eats away at metal components) and scale (mineral deposits that clog pipes and reduce heat transfer).

4. Clean Core Components

Over time, debris can accumulate in the system. Regularly clean or replace water filters and strainers to prevent clogs that would impede water flow. A blockage is a direct cause of overheating.

Common Pitfalls to Avoid

Understanding the risks of improper maintenance helps reinforce the importance of a disciplined approach.

The Risk of Neglect

A clogged filter or a minor leak is not a trivial issue. It can escalate quickly, causing a sudden system shutdown, loss of a valuable sample, or permanent damage to the microwave source or reaction chamber.

The False Economy of Tap Water

Using untreated tap water is a common mistake that guarantees future problems. The dissolved minerals will inevitably precipitate as scale within the narrow cooling channels, insulating the very surfaces you need to cool and leading to costly, difficult-to-fix blockages.

Focusing Only on the "Big" Components

While the pump is vital, a failure is often caused by a smaller, neglected part. A degraded seal, a clogged filter, or a corroded fitting can bring the entire system to a halt. Comprehensive inspection is key.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities.

- If your primary focus is maximum uptime and performance: Implement a daily check of water flow indicators and a weekly visual inspection for leaks, coupled with strict adherence to water replacement schedules.

- If your primary focus is long-term reliability on a budget: Prioritize water quality above all else. Preventing internal corrosion and scale buildup is the most cost-effective way to avoid catastrophic, expensive failures down the line.

- If you are establishing a new MPCVD lab: Create a formal maintenance logbook and schedule from day one. This builds institutional discipline and ensures critical tasks are never overlooked.

A disciplined approach to cooling system maintenance is the most effective investment you can make in the stability and reliability of your MPCVD operations.

Summary Table:

| Maintenance Task | Key Actions | Frequency |

|---|---|---|

| Inspect Water Flow and Pressure | Check pumps for noise, verify cooling tower fans | Daily/Weekly |

| Verify System Integrity for Leaks | Inspect fittings, hoses, and connections for moisture | Weekly |

| Maintain Water Quality | Use deionized/distilled water, replace per schedule | As recommended |

| Clean Core Components | Clean/replace filters and strainers to prevent clogs | Regularly |

Ensure your MPCVD equipment runs flawlessly with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like CVD/PECVD, tailored to your unique needs. Our deep customization capability guarantees precise performance for stable, efficient operations. Contact us today to learn how we can enhance your lab's reliability and results!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- Why is MPCVD considered a cornerstone of modern materials science and engineering? Unlock High-Purity Materials for Innovation