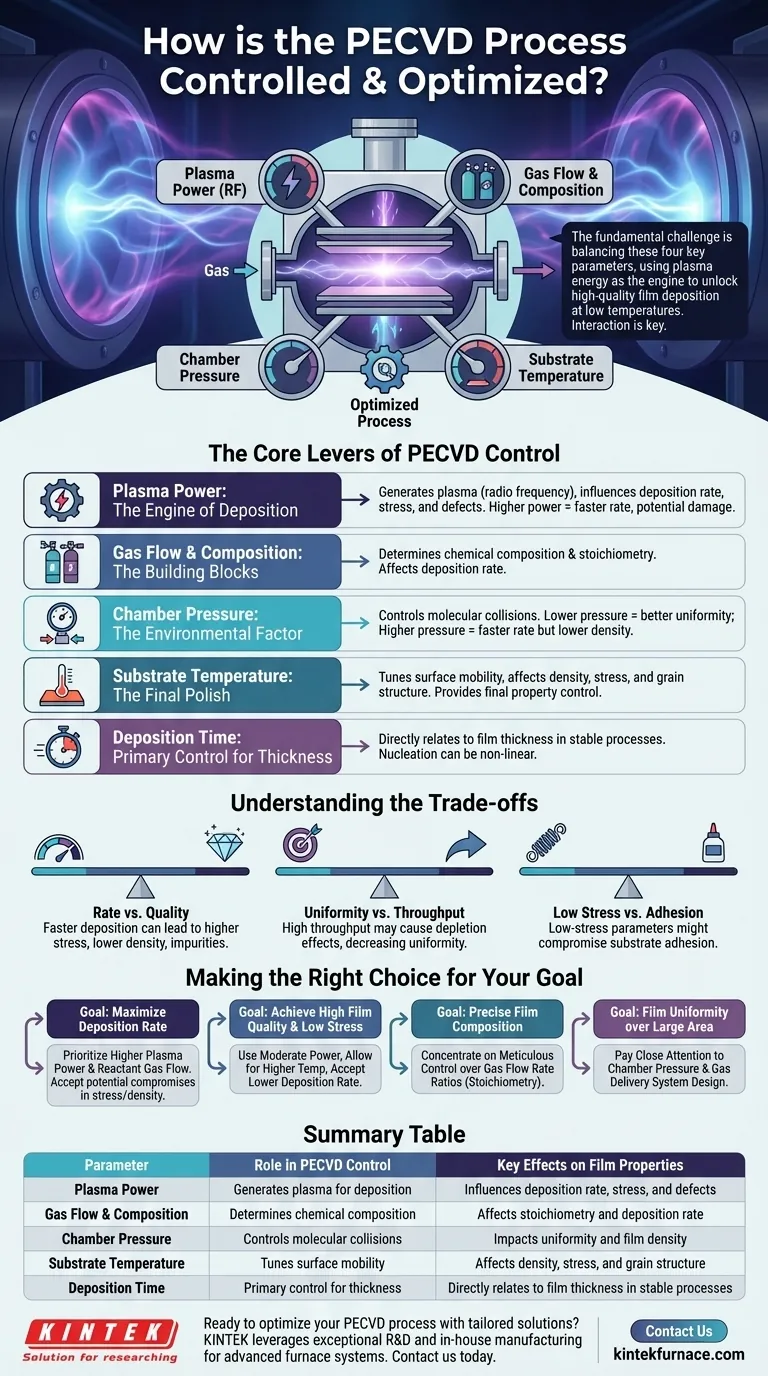

At its core, controlling a PECVD process involves the precise manipulation of four key parameters: plasma power, gas flow rates, chamber pressure, and substrate temperature. By adjusting these variables, you directly influence the chemical reactions occurring within the chamber, allowing you to dictate the final properties of the deposited thin film, from its thickness and density to its electrical and optical characteristics.

The fundamental challenge of PECVD optimization is not in adjusting a single parameter, but in understanding how these variables interact. True control comes from balancing these competing factors to achieve a specific outcome, using plasma energy as the key to unlock high-quality film deposition at low temperatures.

The Core Levers of PECVD Control

Optimizing a Plasma-Enhanced Chemical Vapor Deposition (PECVD) process is a systematic exercise in balancing inputs to achieve a desired output. Each parameter serves as a distinct lever that influences the deposition environment.

Plasma Power: The Engine of Deposition

The applied radio frequency (RF) power is what generates the plasma. This is arguably the most critical parameter in PECVD because it substitutes for the high thermal energy used in conventional CVD.

Increasing plasma power generally increases the density of reactive species (radicals) in the chamber. This can lead to a higher deposition rate, but excessive power can also cause ion bombardment damage to the substrate and the growing film, potentially increasing stress and defects.

Gas Flow & Composition: The Building Blocks

The type and flow rate of reactant gases directly determine the film's chemical composition and stoichiometry. For example, in silicon nitride (Si₃N₄) deposition, the ratio of silane (SiH₄) to ammonia (NH₃) or nitrogen (N₂) is meticulously controlled.

Higher total gas flow rates can increase the supply of reactants, often boosting the deposition rate up to a certain point. However, this must be balanced with the chamber's pumping speed and pressure.

Chamber Pressure: The Environmental Factor

Pressure inside the process chamber influences the mean free path of gas molecules—the average distance a molecule travels before colliding with another.

At lower pressures, the mean free path is longer, leading to more directional deposition and potentially better film uniformity. At higher pressures, more gas-phase collisions occur, which can increase the deposition rate but may decrease film density or lead to particle formation.

Substrate Temperature: The Final Polish

While PECVD's main advantage is its low-temperature operation (typically 350-600 °C), the substrate temperature is still a crucial tuning parameter.

Even modest changes in temperature can significantly affect surface mobility of the depositing atoms, influencing the film's density, stress, and grain structure. It provides a final degree of control over the material's final properties.

Deposition Time: The Primary Control for Thickness

The most straightforward control is deposition time. In a stable, optimized process, film thickness is primarily a function of how long you run the deposition.

However, the relationship is not always perfectly linear. The initial moments of deposition (nucleation) can behave differently, and long deposition times must be managed alongside other parameters to maintain film quality and avoid the accumulation of stress.

Understanding the Trade-offs

Effective PECVD optimization is an exercise in managing trade-offs. Pushing one parameter to its limit to improve a single characteristic often degrades another.

Rate vs. Quality

The most common trade-off is between deposition speed and film quality. Aggressively increasing plasma power and gas flow will deposit material faster, but it can also lead to:

- Higher internal stress in the film.

- Lower film density or higher porosity.

- Incorporation of impurities, such as hydrogen.

- Plasma-induced damage to the underlying substrate.

Uniformity vs. Throughput

Achieving a perfectly uniform film across a large substrate requires careful management of gas flow dynamics, often via a "showerhead" gas inlet.

Optimizing for the highest possible deposition rate can sometimes create depletion effects, where the center of the substrate receives more reactant flux than the edges, leading to a non-uniform film thickness.

Low Stress vs. Adhesion

While PECVD is known for producing low-stress films, the parameters that reduce stress (e.g., lower power, specific gas ratios) might not be the same ones that promote the best adhesion to the substrate. Finding the right balance is essential for device reliability.

Making the Right Choice for Your Goal

Your optimization strategy must be driven by the end goal for your thin film. There is no single "best" set of parameters; there is only the best set for your specific application.

- If your primary focus is maximizing deposition rate: Prioritize higher plasma power and reactant gas flow, but be prepared to accept potential compromises in film stress and density.

- If your primary focus is achieving high film quality and low stress: Use moderate power settings, allow for a slightly higher substrate temperature (within process limits), and accept a lower deposition rate.

- If your primary focus is precise film composition (e.g., refractive index): Concentrate on meticulous control over the flow rate ratios of your reactant gases, as this has the most direct impact on stoichiometry.

- If your primary focus is film uniformity over a large area: Pay close attention to chamber pressure and the physical design of the gas delivery system to ensure even distribution of reactants.

Mastering these interconnected variables transforms PECVD from a complex process into an exceptionally versatile and powerful fabrication tool.

Summary Table:

| Parameter | Role in PECVD Control | Key Effects on Film Properties |

|---|---|---|

| Plasma Power | Generates plasma for deposition | Influences deposition rate, stress, and defects |

| Gas Flow & Composition | Determines chemical composition | Affects stoichiometry and deposition rate |

| Chamber Pressure | Controls molecular collisions | Impacts uniformity and film density |

| Substrate Temperature | Tunes surface mobility | Affects density, stress, and grain structure |

| Deposition Time | Primary control for thickness | Directly relates to film thickness in stable processes |

Ready to optimize your PECVD process with tailored solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and results. Contact us today to discuss how we can support your lab's needs!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab