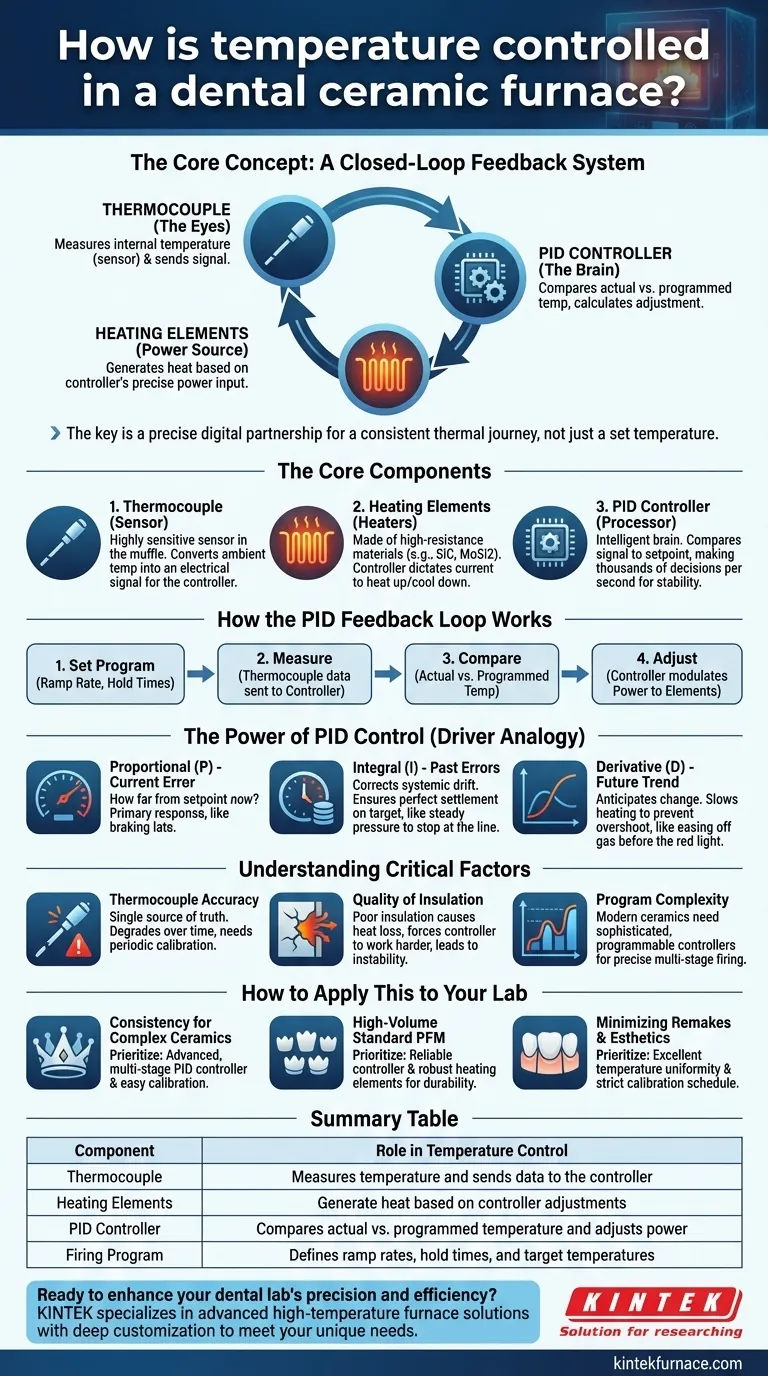

At its core, temperature in a dental ceramic furnace is managed by a closed-loop feedback system. This system continuously measures the internal temperature with a sensor, compares it to the desired temperature program, and makes constant, precise adjustments to the power supplied to the heating elements. This ensures the ceramic restoration is fired with absolute accuracy.

The key to reliable dental restorations is not just reaching a specific temperature, but controlling the entire thermal journey. This is achieved through a precise digital partnership between a temperature sensor (a thermocouple) and an intelligent controller (a PID controller) that work in a constant feedback loop.

The Core Components of Temperature Control

To understand how the system achieves such precision, we must look at its three critical components. Each has a distinct and essential role in the process.

The Thermocouple: The Eyes of the Furnace

A thermocouple is a highly sensitive and durable temperature sensor placed inside the furnace's heating chamber (muffle).

Its sole job is to measure the exact ambient temperature surrounding the dental restoration. It then converts this temperature reading into a small electrical signal that it sends to the controller.

The Heating Elements: The Source of Power

These are the components that generate the heat. They are typically made of high-resistance materials like silicon carbide or molybdenum disilicide.

The controller dictates the precise amount of electrical current sent to these elements, causing them to heat up or cool down as needed to follow the programmed firing cycle.

The Controller: The Brain of the Operation

The controller is the central processor that makes all the decisions. It receives the temperature signal from the thermocouple and compares it to the pre-programmed setpoint for that exact moment in time.

Modern furnaces use a highly intelligent type of controller known as a PID controller. This is the key to achieving a stable and accurate firing cycle.

How the System Works: The PID Feedback Loop

The process is a continuous cycle of measurement and adjustment that happens many times per second. It is far more sophisticated than a simple on/off thermostat.

Setting the Firing Program

First, the dental technician inputs the desired firing parameters into the furnace's control panel. This includes not just the final temperature but also the rate of temperature increase (the "ramp rate") and how long to hold at specific temperatures ("hold times").

Measure, Compare, Adjust

Once the program starts, the feedback loop begins:

- The thermocouple measures the current temperature.

- It sends this data to the PID controller.

- The controller compares the actual temperature to the programmed temperature for that instant.

- The controller then calculates the precise power adjustment needed for the heating elements to close any gap between the two.

The Power of PID Control

A PID (Proportional-Integral-Derivative) controller is what separates a professional dental furnace from a simple oven. It intelligently modulates power based on three factors:

- Proportional (P): How far is the current temperature from the setpoint right now? This is the primary response.

- Integral (I): What is the accumulation of past errors? This corrects for any systemic drift and ensures the furnace settles perfectly on the target temperature without undershooting or overshooting.

- Derivative (D): How quickly is the temperature changing? This allows the controller to anticipate where the temperature is headed and proactively slow down heating to prevent overshooting the target.

Think of it like an expert driver approaching a red light. They don't just slam on the brakes at the last second (proportional). They ease off the gas (derivative) and apply steady pressure (integral) to come to a perfect, smooth stop right at the line.

Understanding the Critical Factors

Even with a perfect system, real-world variables can impact performance. Understanding them is key to ensuring consistent results.

Thermocouple Accuracy and Longevity

The thermocouple is the single source of truth for the entire system. If it provides an inaccurate reading, the entire firing cycle will be incorrect, even if the controller functions perfectly.

Thermocouples degrade over time and require periodic calibration or replacement to maintain the furnace's accuracy.

Quality of Insulation

The heating chamber must be extremely well-insulated. Poor insulation or cracks in the muffle cause heat to escape, forcing the controller to work much harder to maintain temperature.

This can lead to temperature instability and inconsistent firing results, especially in different areas of the firing tray.

Program Complexity

Modern ceramics, like zirconia and lithium disilicate, require complex, multi-stage firing programs. A furnace's value is directly tied to the sophistication and programmability of its controller, allowing for precise customization for these advanced materials.

How to Apply This to Your Lab

Your choice and use of a furnace should be guided by the clinical and business outcomes you need to achieve.

- If your primary focus is consistency for complex ceramics: Prioritize a furnace with an advanced, multi-stage programmable PID controller and features for easy thermocouple calibration.

- If your primary focus is high-volume production of standard PFM cases: A reliable furnace with a proven digital controller and robust heating elements is essential for durability and uptime.

- If your primary focus is minimizing remakes and ensuring esthetics: Invest in a furnace known for its temperature uniformity across the entire firing tray and follow a strict thermocouple calibration schedule.

Understanding this technology empowers you to produce consistent, high-quality restorations that you and your patients can rely on.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| Thermocouple | Measures temperature and sends data to the controller |

| Heating Elements | Generate heat based on controller adjustments |

| PID Controller | Compares actual vs. programmed temperature and adjusts power |

| Firing Program | Defines ramp rates, hold times, and target temperatures |

Ready to enhance your dental lab's precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs—ensuring consistent, high-quality restorations for materials like zirconia and lithium disilicate. Contact us today to discuss how our tailored furnace solutions can elevate your workflow and reduce remakes!

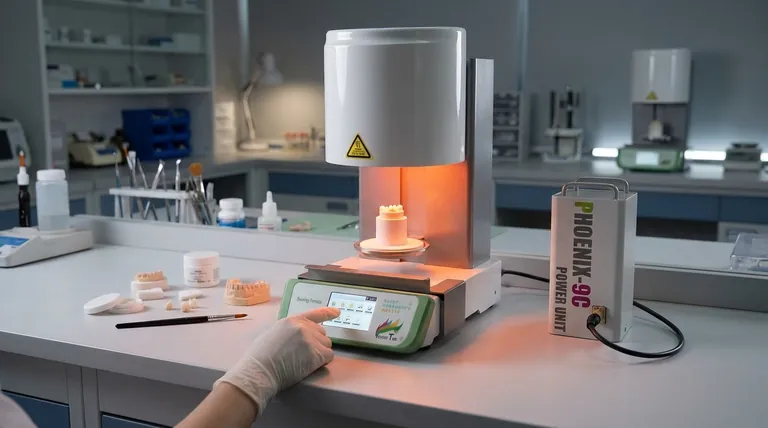

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations