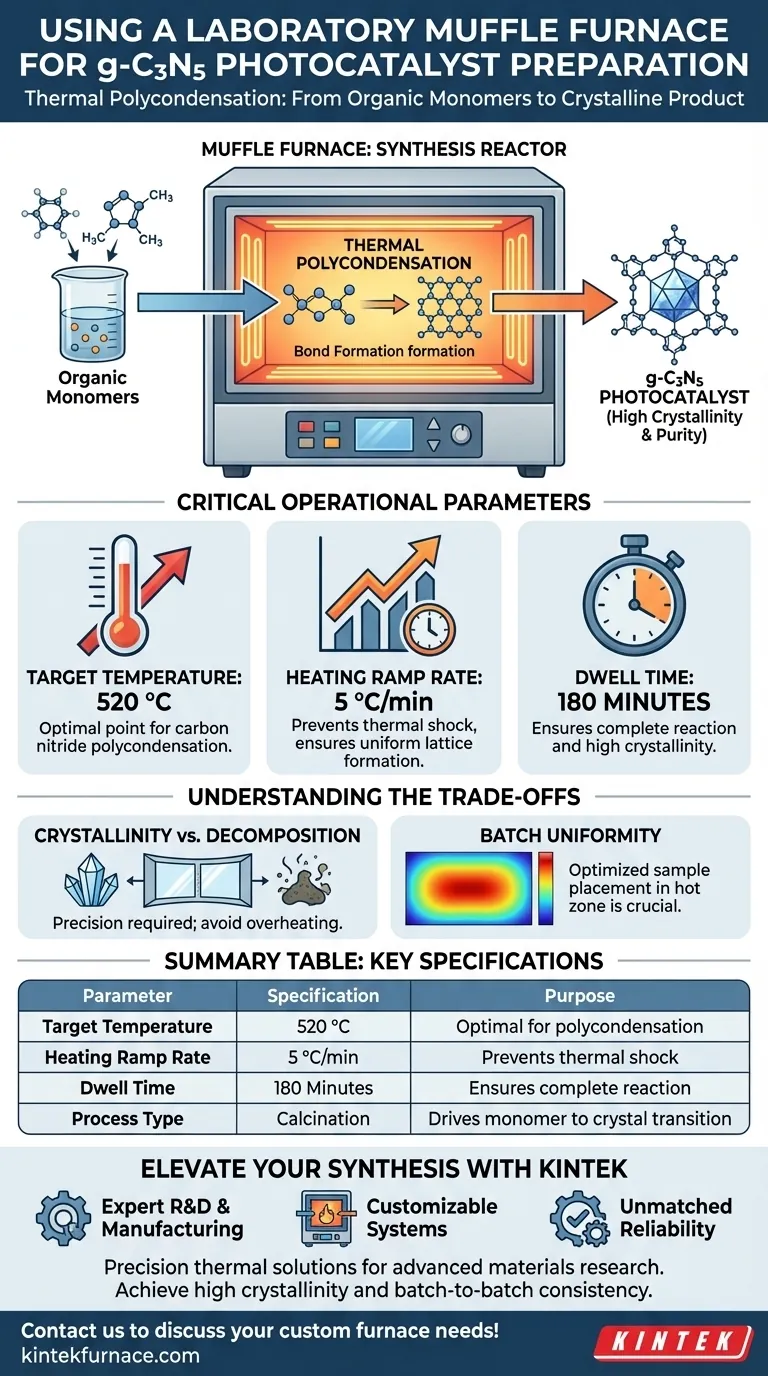

The primary role of a laboratory muffle furnace in preparing g-C3N5 is to provide a precisely controlled environment for thermal polycondensation.

By subjecting organic monomers to a specific heating protocol—a ramp rate of 5 °C/min up to 520 °C, held for 180 minutes—the furnace drives the chemical reaction necessary to form the carbon nitride crystal structure. This calcination process ensures the conversion of precursors into a pure, highly crystalline g-C3N5 product.

Core Takeaway The muffle furnace is not merely a heating device; it acts as a synthesis reactor that facilitates the structural transformation of organic monomers. Strict adherence to the temperature profile (520 °C) and duration (180 mins) is critical to achieving the high crystallinity and purity required for effective photocatalysis.

The Mechanism of Thermal Polycondensation

Driving Chemical Transformation

The fundamental function of the muffle furnace in this context is to facilitate thermal polycondensation.

This is a chemical process where organic monomers are linked together to form polymer chains. The heat supplied by the furnace provides the activation energy required to break existing bonds in the monomers and form the stable carbon nitride framework of g-C3N5.

From Monomer to Crystal

The furnace environment enables the complete transformation of the starting material into a defined crystal structure.

Unlike simple drying or annealing, this step reconstructs the atomic arrangement of the material. The result is a transition from a disordered organic state to a rigid, ordered g-C3N5 crystal structure.

Critical Operational Parameters

Precise Temperature Control

The specific target temperature for g-C3N5 synthesis is 520 °C.

Maintaining this exact temperature is vital. It is the specific thermal point where the polycondensation reaction occurs most effectively for this specific allotrope of carbon nitride, ensuring the product reaches the correct phase.

Controlled Heating Rate

The heating rate is set to a steady 5 °C/min.

This gradual increase in temperature prevents thermal shock and ensures uniform heating throughout the sample. A controlled ramp allows the chemical reactions to proceed sequentially and stabilizes the developing crystal lattice.

Sustained Dwell Time

The furnace must maintain the peak temperature for 180 minutes.

This "dwell time" ensures the reaction reaches completion throughout the entire bulk of the material. Insufficient time at this temperature could lead to incomplete polymerization, resulting in lower crystallinity or residual impurities.

Understanding the Trade-offs

Crystallinity vs. Decomposition

While high heat is necessary for crystallization, there is a narrow window of operation.

The muffle furnace must provide heat high enough to induce polycondensation (520 °C) but controlled enough to prevent the material from decomposing or oxidizing into unwanted byproducts. Precision in the furnace's controller is essential to stay within this window.

Batch Uniformity

A common challenge in static air furnaces (like box-type muffle furnaces) is thermal gradients.

While the setpoint may be 520 °C, the center of the furnace chamber may differ slightly from the edges. This can lead to minor variations in the crystallinity of the g-C3N5 if the sample placement is not optimized within the uniform hot zone.

Making the Right Choice for Your Goal

To maximize the quality of your g-C3N5 photocatalyst, tailor your furnace operations to your specific objectives:

- If your primary focus is High Purity: Strictly verify the calibration of your furnace to ensure the internal temperature is exactly 520 °C, as deviation can alter the phase composition.

- If your primary focus is Structural Integrity: Adhere rigidly to the 5 °C/min ramp rate to prevent rapid outgassing or structural defects during the formation of the crystal lattice.

- If your primary focus is Reaction Completeness: Ensure the 180-minute dwell time is uninterrupted, as cutting this short will result in amorphous, low-performance material.

Precision in the thermal profile is the single most important factor in determining the final catalytic efficiency of g-C3N5.

Summary Table:

| Parameter | Specification | Purpose in g-C3N5 Synthesis |

|---|---|---|

| Target Temperature | 520 °C | Optimal point for carbon nitride polycondensation |

| Heating Ramp Rate | 5 °C/min | Prevents thermal shock and ensures uniform lattice formation |

| Dwell Time | 180 Minutes | Ensures complete reaction and high crystallinity |

| Process Type | Calcination | Drives the transition from organic monomer to crystal structure |

Elevate Your Materials Synthesis with KINTEK

Precision is the difference between a low-performance sample and a high-efficiency photocatalyst. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, and Vacuum furnaces, specifically designed to handle the rigorous demands of advanced materials research like g-C3N5 synthesis.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Our systems offer the superior temperature uniformity and programmable logic controllers (PLC) required for strict 5°C/min ramp rates.

- Customizable Systems: We tailor our lab high-temp furnaces to your unique atmospheric or spatial needs.

- Unmatched Reliability: Achieve high crystallinity and batch-to-batch consistency with our precision-engineered heating elements.

Ready to optimize your thermal polycondensation process? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Shaowei Qin, Jianhui Jiang. A high-performance g-C3N5/Bi2SiO5 heterojunction photocatalyst induced by constructing S-scheme electron-highways. DOI: 10.1038/s41598-025-85268-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a Muffle Furnace play in biomass pellet torrefaction? Optimize Your High-Temperature Processing

- In which industries is the muffle furnace commonly used? Essential for Materials Science and Quality Control

- What are the main industries that use muffle furnaces? Essential for Clean Heat in Labs and Manufacturing

- What are the common uses of muffle furnaces? Essential for Material Analysis, Heat Treatment, and Synthesis

- How does the built-in venting system in a muffle furnace improve performance? Boost Durability and Safety in Your Lab

- Why is an industrial muffle furnace required to process sugar beet samples at 550 °C for crude ash determination?

- What emergency preparedness measures should be in place for muffle furnace operation? Ensure Lab Safety with Proactive Protocols

- How does a laboratory drying oven facilitate moisture removal? Achieve Precise Data with KINTEK Drying Solutions