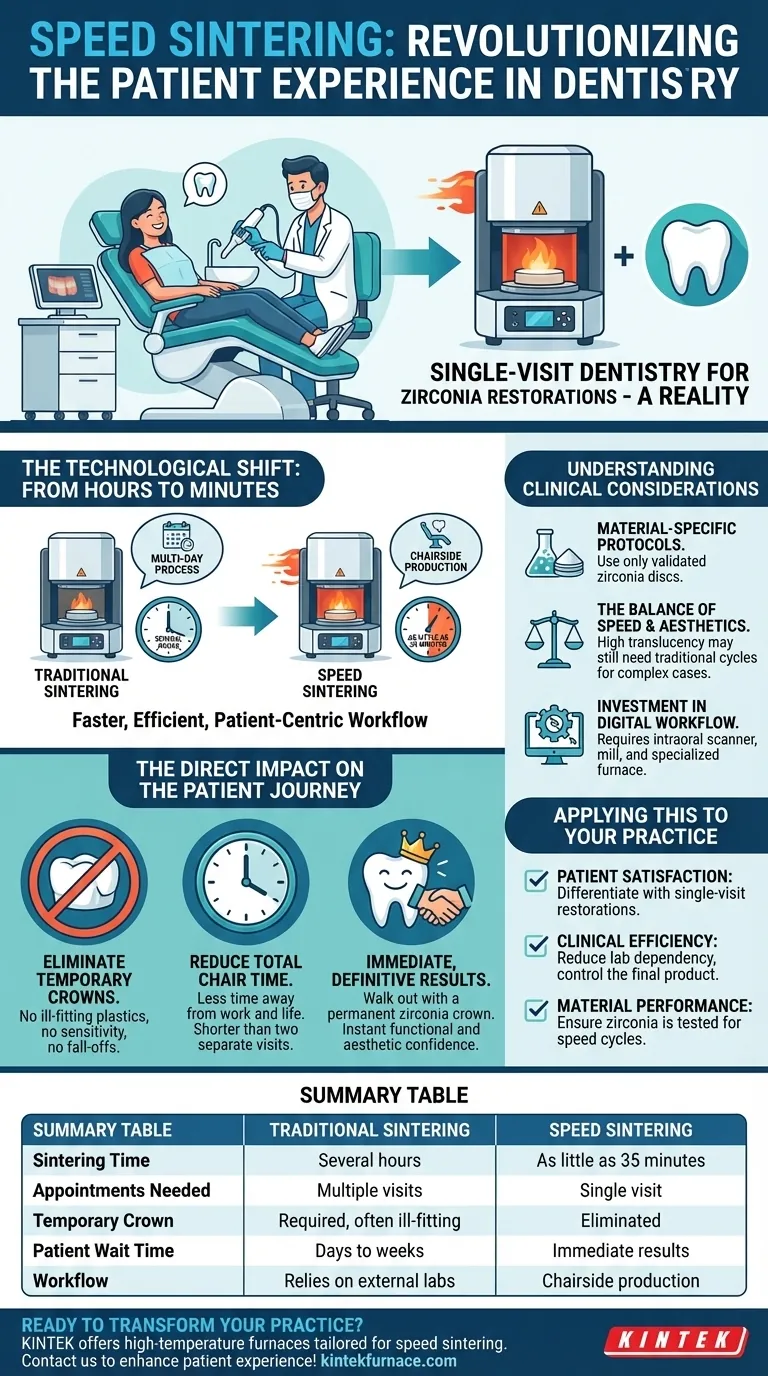

In short, speed sintering has revolutionized the patient experience by making single-visit dentistry for high-strength zirconia restorations a reality. By reducing a multi-hour or multi-day fabrication process to under an hour, it eliminates the need for temporary crowns and follow-up appointments, delivering immediate and permanent results.

The true impact of speed sintering goes beyond mere convenience. It fundamentally transforms the restorative workflow, shifting the standard of care from a prolonged, multi-stage process to an efficient, patient-centric experience that delivers a final restoration in a single appointment.

How Speed Sintering Redefined the Dental Appointment

To understand the impact on the patient, you first have to understand the underlying technological shift. Sintering is the critical heating process that hardens a milled zirconia crown to its final, durable state.

From Hours to Minutes

Traditionally, sintering zirconia was a bottleneck. The process took place in a conventional furnace over several hours, making same-day restorations impossible.

Speed sintering uses advanced, high-temperature furnaces to complete this process in as little as 35 minutes. This efficiency gain is the core enabler of the single-visit workflow.

The Power of Chairside Production

This speed allows the entire restoration process—from digital scan to final cementation—to happen "chairside" while the patient is in the office. The dentist can design, mill, and sinter the crown without relying on an external lab.

The Direct Impact on the Patient Journey

For the patient, this technological change translates into tangible, significant benefits that address common frustrations with dental work.

Eliminating the Temporary Crown

Perhaps the most significant improvement is the elimination of the temporary restoration. Patients no longer have to endure ill-fitting plastic temporaries that can cause sensitivity or fall off between appointments.

Reducing Total Chair Time

While a single-visit appointment is longer than a traditional prep appointment, it is significantly shorter than the total time required for two separate visits. This means less time away from work and life.

Immediate, Definitive Results

Patients leave the office with their final, permanent zirconia crown. This removes the anxiety and uncertainty of a multi-week waiting period and provides immediate functional and aesthetic confidence.

Understanding the Clinical Considerations

While the patient benefits are clear, dental professionals must navigate certain technical considerations to ensure successful outcomes. This technology is not a universal substitute for all cases.

Material-Specific Protocols

Not all zirconia materials are designed for speed sintering. Only specific, validated zirconia discs should be used, as rapid heating can compromise the strength or aesthetics of materials not formulated for it.

The Balance of Speed and Aesthetics

While modern speed-sintered zirconia offers excellent aesthetics, the most highly translucent materials used for complex anterior cases may still achieve their peak appearance with a slower, traditional sintering cycle. The clinician must choose the right material for the case.

Investment in a Digital Workflow

Adopting speed sintering requires a significant investment in a full digital ecosystem, including an intraoral scanner, a milling unit, and the specialized furnace itself.

Applying This to Your Practice

Adopting speed sintering is a strategic decision that aligns the practice with the modern patient's expectation for efficiency and immediate results.

- If your primary focus is patient satisfaction: Offering single-visit restorations is one of the most powerful ways to differentiate your practice and exceed patient expectations.

- If your primary focus is clinical efficiency: A chairside speed sintering workflow reduces dependency on external labs, minimizes scheduling complexity, and allows for greater control over the final product.

- If your primary focus is material performance: Ensure you are using zirconia blocks that have been explicitly tested and validated for the specific speed sintering cycle you plan to use.

Ultimately, speed sintering empowers dental professionals to deliver a higher standard of care that respects the patient's time and delivers lasting results without the wait.

Summary Table:

| Aspect | Traditional Sintering | Speed Sintering |

|---|---|---|

| Sintering Time | Several hours | As little as 35 minutes |

| Appointments Needed | Multiple visits | Single visit |

| Temporary Crown | Required, often ill-fitting | Eliminated |

| Patient Wait Time | Days to weeks | Immediate results |

| Workflow | Relies on external labs | Chairside production |

Ready to transform your dental practice with advanced sintering solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnaces tailored for speed sintering. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to meet the unique needs of dental laboratories. With strong deep customization capabilities, we ensure precise performance for your zirconia restorations. Contact us today to enhance patient experience and boost efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision