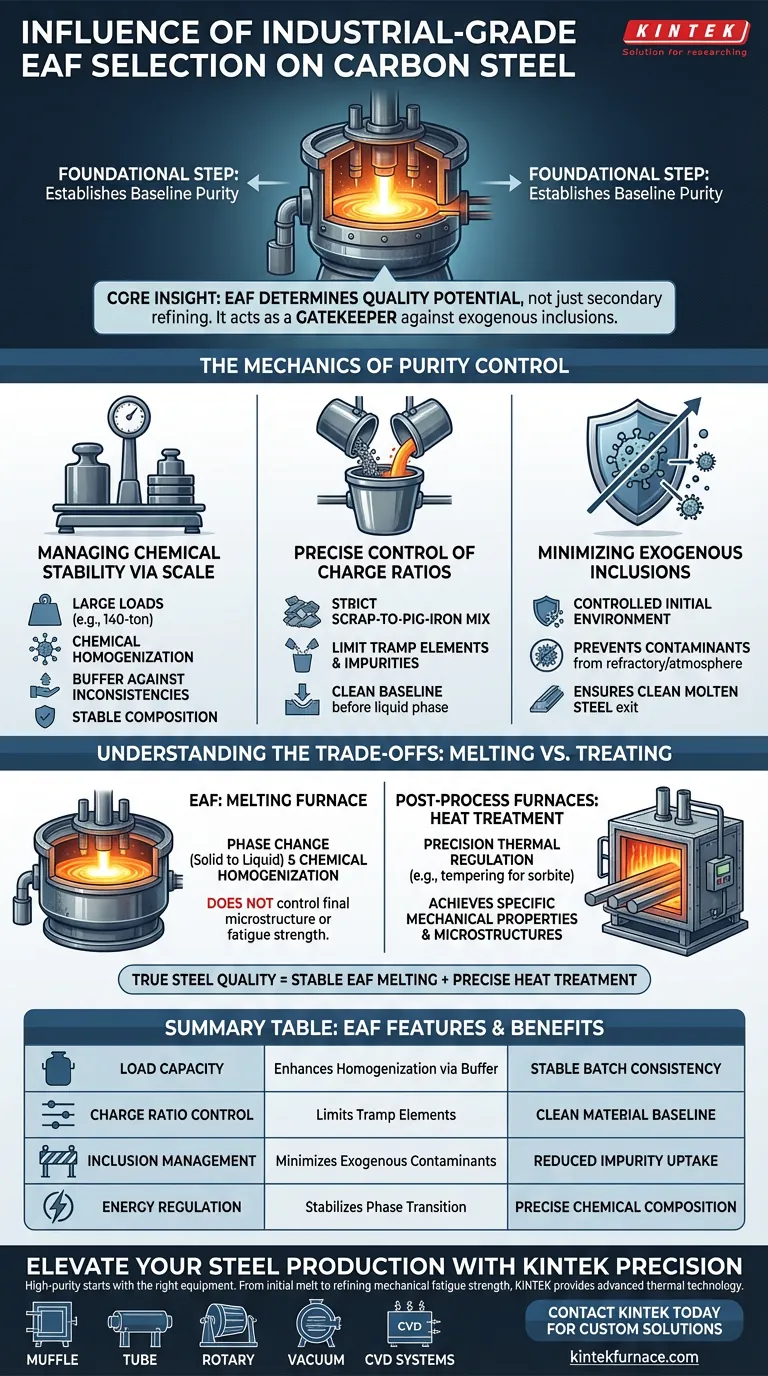

The selection of an industrial-grade Electric Arc Furnace (EAF) is the foundational step in establishing the baseline purity of carbon steel. It influences purity by enabling the precise management of large-scale loads, specifically through the control of energy input and the charging ratio of raw materials. This control is essential for stabilizing the chemical composition and minimizing external contaminants before the steel reaches secondary refining.

Core Insight While secondary refining is often credited with final purity, the EAF determines the quality potential of the melt. By stabilizing the chemical composition of large volumes and optimizing the scrap-to-pig-iron mix, the furnace acts as a gatekeeper against the introduction of exogenous non-metallic inclusions.

The Mechanics of Purity Control

Managing Chemical Stability via Scale

The capacity of an industrial EAF directly impacts the consistency of the steel.

Furnaces designed for large-scale operations, such as those processing 140-ton loads, offer significant advantages in chemical homogenization.

The sheer volume of the melt helps buffer against minor inconsistencies in raw materials, resulting in a more stable chemical composition across the entire batch.

Precise Control of Charge Ratios

The purity of the final product is heavily dictated by what enters the furnace.

High-grade EAFs allow operators to strictly control the "charging ratio" between scrap steel and pig iron.

Optimizing this ratio is the primary method for controlling the initial levels of tramp elements and impurities, setting a clean baseline before the steel is liquid.

Minimizing Exogenous Inclusions

Purity is not just about removing impurities; it is about preventing them.

The EAF provides a controlled initial container environment during the chaotic melting phase.

A properly selected furnace reduces the introduction of exogenous non-metallic inclusions—contaminants that enter the melt from the refractory lining or the atmosphere—ensuring the molten steel leaves the furnace as clean as possible.

Understanding the Trade-offs: Melting vs. Treating

It is critical to distinguish between the furnace used for melting and the furnace used for heat treatment.

The Limit of the EAF

The EAF is designed for phase change (solid to liquid) and chemical homogenization.

It does not control the final microstructure or fatigue strength of the solid steel; its role ends once the molten steel is tapped for refining or casting.

The Role of Post-Process Furnaces

While the EAF sets the purity, achieving specific mechanical properties requires a different equipment set, often confused with melting furnaces.

As noted in supplementary technical context, precise microstructures (such as tempered sorbite) are achieved using high-temperature electric furnaces capable of long tempering cycles (e.g., 120 minutes at 880°C).

Do not expect an EAF to perform the precision thermal regulation required for austenitization or tempering.

Making the Right Choice for Your Goal

To achieve high-integrity carbon steel, you must match the furnace capabilities to your specific stage of production.

- If your primary focus is Melt Cleanliness: Prioritize an EAF with high-capacity load management to ensure chemical stability and reduced inclusion uptake during the solid-to-liquid phase.

- If your primary focus is Mechanical Fatigue Strength: Recognize that while the EAF provides the clean material, you must invest in separate high-stability thermal equipment to control the transformation from martensite to sorbite.

True steel quality is achieved when the stability of the melting furnace is paired with the precision of subsequent heat treatment.

Summary Table:

| Feature | Impact on Carbon Steel Purity | Primary Benefit |

|---|---|---|

| Load Capacity | Enhances chemical homogenization via volume buffering | Stable batch consistency |

| Charge Ratio Control | Limits tramp elements through scrap/pig iron optimization | Clean material baseline |

| Inclusion Management | Minimizes exogenous non-metallic contaminants | Reduced impurity uptake |

| Energy Regulation | Stabilizes solid-to-liquid phase transition | Precise chemical composition |

Elevate Your Steel Production with KINTEK Precision

High-purity carbon steel starts with the right equipment. Whether you are managing the initial melt or refining mechanical fatigue strength, KINTEK provides the advanced thermal technology required for excellence.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab and industrial solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our high-temperature furnaces are fully customizable to meet your unique metallurgical needs, ensuring you achieve the exact microstructures—from austenitization to tempering—that your application demands.

Ready to optimize your heat treatment process? Contact KINTEK today to discuss your custom solution.

Visual Guide

References

- Tomasz Lipiński. Analysis of the Distribution of Non-Metallic Inclusions and Its Impact on the Fatigue Strength Parameters of Carbon Steel Melted in an Electric Furnace. DOI: 10.3390/ma17246151

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does induction heating contribute to a cleaner work environment? Boost Quality & Sustainability

- What are the energy efficiency advantages of induction melting furnaces? Achieve 30-80% Greater Energy Savings

- What is the function of a Vacuum Induction Heating Furnace in research? Synthesis and Purity of Copper-Bearing Steel

- How does a directional solidification furnace contribute to the manufacturing of high-purity Cu-Fe-Zn alloy ingots?

- What role does the high-frequency induction coil play in density measurement with EML? Unlock Precise Metal Analysis

- What is the primary method recommended for smelting precious metals? Induction Furnace for High Purity & Efficiency

- What role does a high-vacuum melting furnace play in the modification of Ni 620 brazing filler metal with tungsten?

- What is the purpose of an induction furnace? Achieve Superior Metal Melting with Precision & Purity