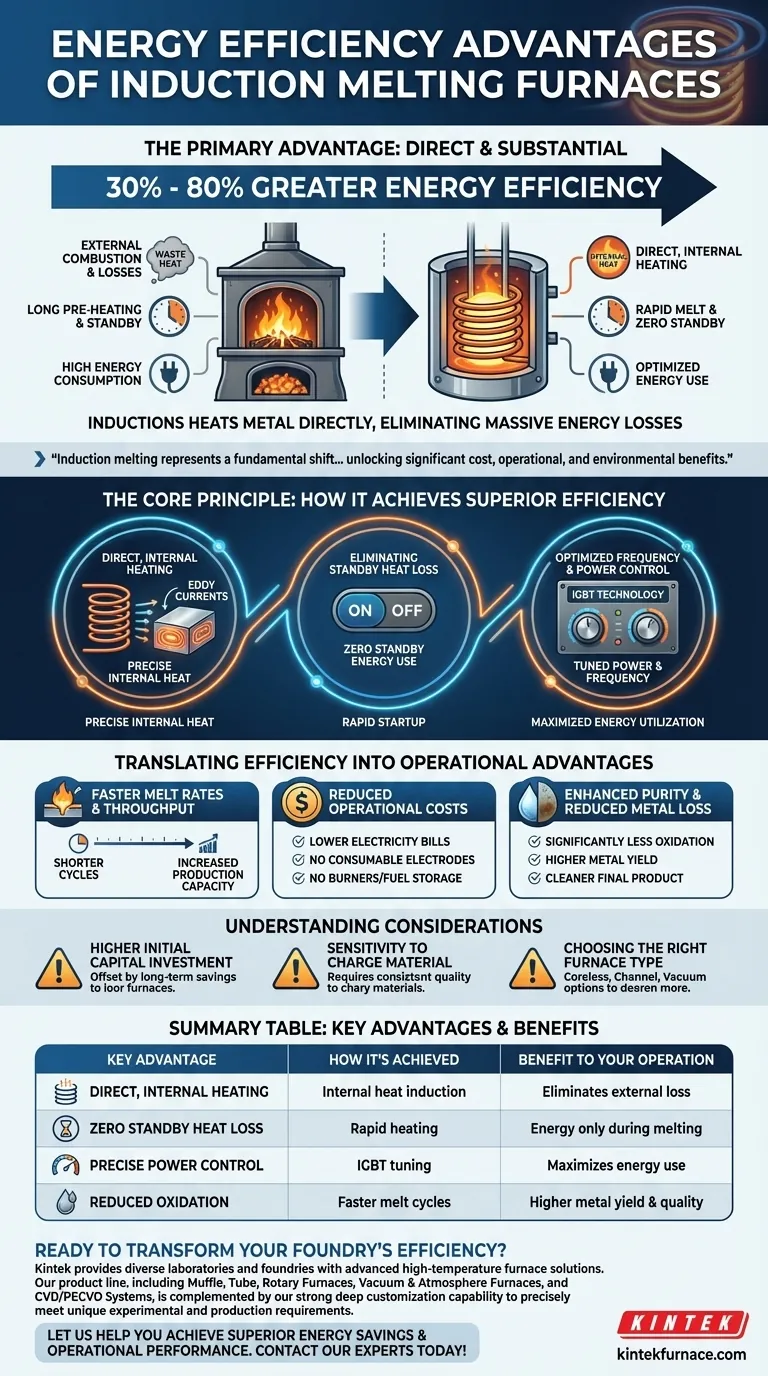

The primary advantage is direct and substantial. Compared to traditional fuel-fired or electric arc furnaces, induction melting furnaces offer between 30% and 80% greater energy efficiency. This is achieved because induction heats the metal directly and internally, eliminating the massive energy losses associated with external combustion, heat transfer, and standby operation.

Induction melting represents a fundamental shift in heating philosophy. By using electromagnetic fields to generate heat inside the target material, it bypasses the inherent waste of external heating methods, unlocking significant cost, operational, and environmental benefits.

The Core Principle: How Induction Achieves Superior Efficiency

To understand the advantages of induction melting, you must first understand its unique heating mechanism. Unlike conventional furnaces that burn fuel to create a hot environment, induction furnaces turn the metal itself into the source of heat.

Direct, Internal Heating

An induction furnace uses a powerful coil to generate a fluctuating magnetic field. When conductive material like metal is placed within this field, it induces strong electrical currents—known as eddy currents—to flow within the metal. The metal's natural resistance to these currents generates precise, rapid, and internal heat. This process avoids the massive energy loss that occurs when trying to transfer heat from an external flame or element through the air and crucible walls.

Eliminating Standby Heat Loss

Traditional furnaces often need to be kept hot between melts to avoid long pre-heating cycles and thermal shock to their refractory linings. This standby state consumes a tremendous amount of energy with zero productive output. Induction furnaces, by contrast, can be shut down completely. Because they heat the charge so rapidly (often in minutes), there is zero standby heat loss, and energy is only consumed during the active melting process.

Optimized Frequency and Power Control

Modern induction systems, particularly those using IGBT (Insulated-Gate Bipolar Transistor) technology, provide precise control over the power and frequency. This allows the system to be tuned perfectly to the type of metal, the size of the charge, and the phase of the melt. This ensures that nearly every kilowatt of energy is used effectively, minimizing waste.

Translating Efficiency into Operational Advantages

This fundamental energy efficiency creates cascading benefits that improve an entire foundry's operation, from throughput to material cost.

Faster Melt Rates and Throughput

Because heating is so direct and rapid—capable of reaching over 2,000°F in seconds—melt cycles are significantly shorter. This dramatic reduction in "time-to-molten" allows for a more continuous workflow, increasing the overall production capacity of the facility without adding more floor space.

Reduced Operational Costs

Efficiency directly lowers electricity bills, but the savings go further. Induction furnaces do not require consumable electrodes, burners, or fuel storage infrastructure. This eliminates the cost of purchasing, storing, and handling combustible fuels and reduces the maintenance associated with these complex systems.

Enhanced Purity and Reduced Metal Loss

The speed of induction melting minimizes the time the molten metal is exposed to the atmosphere. This leads to significantly less oxidation (dross or slag formation) compared to slower methods. The result is a higher metal yield from your charge material and a cleaner, higher-quality final product. In vacuum induction systems, this advantage is maximized, allowing for the melting of highly reactive alloys like titanium without contamination.

Understanding the Trade-offs and Considerations

While highly efficient, induction technology is not a universal solution without its own set of considerations.

Higher Initial Capital Investment

The technology powering an induction furnace is more sophisticated than that of a simple cupola or resistance furnace. Consequently, the initial purchase and installation cost is typically higher. This investment is offset over time by lower energy and operational expenses.

Sensitivity to Charge Material

Induction furnaces perform best with a charge of a known and consistent quality. Very large, bulky scrap may melt less efficiently than smaller, more uniform pieces. Likewise, heavily contaminated or dirty scrap can introduce impurities into the melt and affect the final chemistry.

Choosing the Right Furnace Type

The term "induction furnace" covers several designs. A coreless furnace is highly flexible for different alloys, while a channel furnace is extremely efficient for holding and melting large volumes of a single alloy. A vacuum induction furnace is a specialized system for achieving the highest purity. Selecting the wrong type for your application can undermine potential efficiency gains.

Making the Right Choice for Your Foundry

The decision to adopt induction technology should be aligned with your specific operational goals.

- If your primary focus is maximizing energy cost savings and flexibility: An IGBT-powered coreless induction furnace offers the best blend of high efficiency and the versatility to handle various alloys and melt sizes.

- If your primary focus is producing high-purity or reactive alloys: A vacuum induction melting (VIM) furnace is the correct choice, as its primary advantage is preventing contamination, which is enabled by its efficient heating method.

- If your primary focus is high-volume, continuous melting of a single alloy: A channel induction furnace can be exceptionally efficient for this task, acting as a large, continuously-fed reservoir with very low energy consumption for holding metal at temperature.

Ultimately, adopting induction technology is a strategic decision that trades a higher initial investment for profound long-term gains in efficiency, product quality, and environmental compliance.

Summary Table:

| Key Advantage | How It's Achieved | Benefit to Your Operation |

|---|---|---|

| Direct, Internal Heating | Electromagnetic fields induce heat directly within the metal charge. | Eliminates energy loss from external heat transfer. |

| Zero Standby Heat Loss | Rapid heating allows the furnace to be shut down between melts. | Energy is only consumed during active melting, reducing costs. |

| Precise Power Control | IGBT technology allows tuning for specific metals and melt phases. | Maximizes energy use, minimizing waste. |

| Reduced Oxidation | Faster melt cycles minimize metal exposure to the atmosphere. | Higher metal yield and cleaner final product quality. |

Ready to Transform Your Foundry's Efficiency?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental and production requirements.

Let us help you achieve superior energy savings and operational performance. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification