The oil quenching process acts as a controlled structural trigger, rapidly cooling bearing steel from a heated state to transform it into a hardened, durable component. Specifically, by cooling the steel from an austenitizing temperature of approximately 840°C using oil, the process converts the internal microstructure from austenite into martensite while actively mitigating the risks of physical damage.

The core value of oil quenching lies in its "moderate" cooling rate. It strikes a critical balance: it is fast enough to harden the steel matrix but controlled enough to prevent the cracking and severe distortion caused by more aggressive cooling methods.

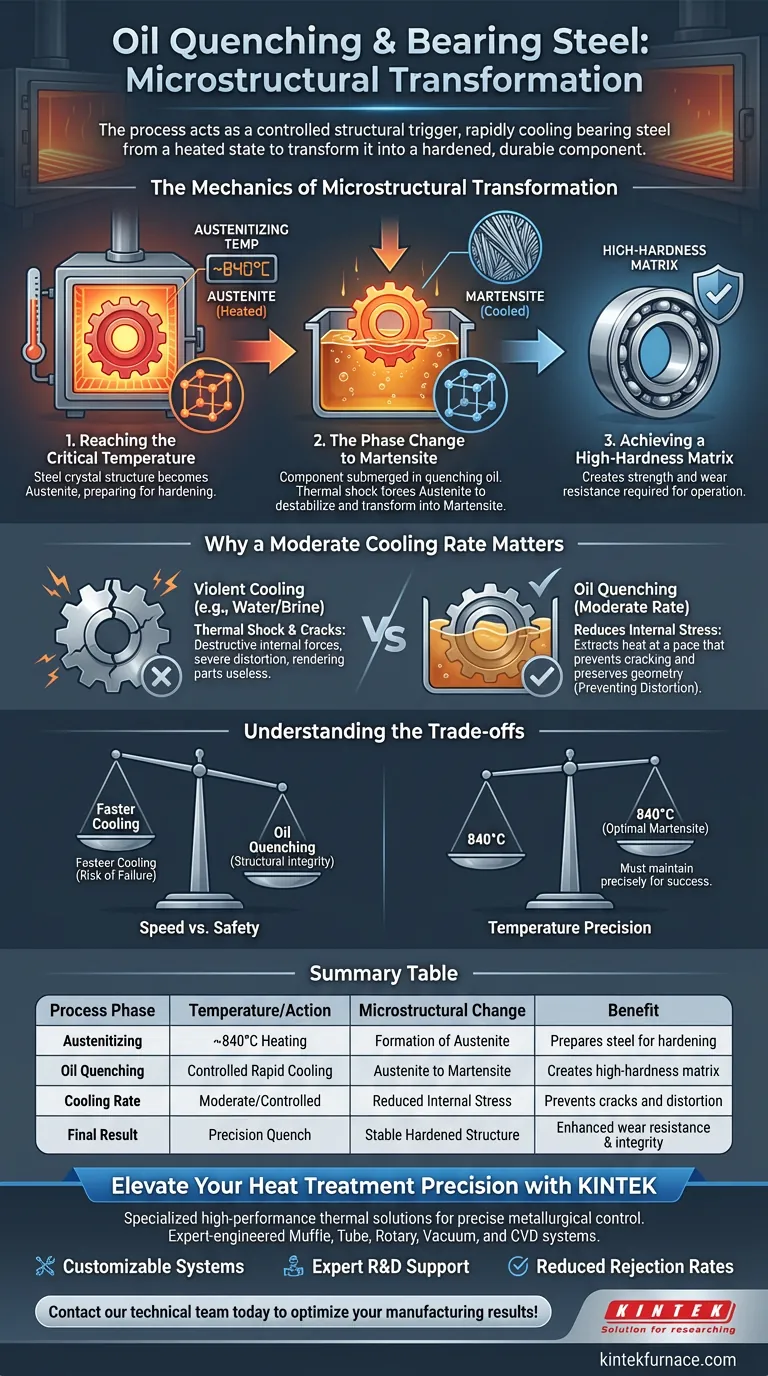

The Mechanics of Microstructural Transformation

Reaching the Critical Temperature

The transformation process begins by heating the bearing steel to an austenitizing temperature of approximately 840°C. At this thermal peak, the steel’s crystal structure becomes austenite, a phase necessary to prepare the metal for hardening.

The Phase Change to Martensite

Once the component is submerged in the quenching oil, the temperature drops rapidly. This thermal shock forces the austenite to destabilize and transform into martensite.

Achieving a High-Hardness Matrix

The formation of martensite is the ultimate goal of this process. This microstructural change creates a high-hardness matrix, endowing the bearing steel with the strength and wear resistance required for operation.

Why a Moderate Cooling Rate Matters

Avoiding Thermal Shock

If bearing steel is cooled too violently, the internal forces become destructive. Rapid contraction can lead to the formation of quenching cracks, rendering the part useless.

Reducing Internal Stress

The specialized furnace uses oil because it provides a moderate cooling rate. Unlike water or brine, oil extracts heat at a pace that effectively reduces cooling stresses throughout the component.

Preventing Distortion

Dimensional accuracy is critical for bearings. The controlled nature of the oil quench ensures the part hardens without suffering severe distortion, preserving the geometry of the component.

Understanding the Trade-offs

Speed vs. Safety

While faster cooling media might theoretically produce a harder surface, they drastically increase the risk of immediate failure. Oil quenching accepts a slightly slower rate to prioritize the structural integrity of the steel.

Temperature Precision

The success of this transformation relies heavily on the initial heating accuracy. If the furnace does not maintain the 840°C austenitizing temperature precisely, the oil quench cannot induce the optimal martensitic transformation.

Making the Right Choice for Your Process

Depending on your specific manufacturing goals, the utility of the oil quenching furnace varies.

- If your primary focus is structural reliability: Prioritize oil quenching to minimize the rejection rate caused by cracks and warping during the hardening phase.

- If your primary focus is material hardness: Ensure your furnace consistently holds the 840°C austenitizing baseline to maximize the volume of martensite formed during the cool-down.

By controlling the thermal descent, you turn a piece of raw steel into a precision component capable of enduring immense loads.

Summary Table:

| Process Phase | Temperature/Action | Microstructural Change | Benefit |

|---|---|---|---|

| Austenitizing | ~840°C Heating | Formation of Austenite | Prepares steel for hardening |

| Oil Quenching | Controlled Rapid Cooling | Austenite to Martensite | Creates high-hardness matrix |

| Cooling Rate | Moderate/Controlled | Reduced Internal Stress | Prevents cracks and distortion |

| Final Result | Precision Quench | Stable Hardened Structure | Enhanced wear resistance & integrity |

Elevate Your Heat Treatment Precision with KINTEK

Don't compromise on structural integrity. At KINTEK, we specialize in high-performance thermal solutions designed for precise metallurgical control. Whether you are quenching bearing steel or developing advanced materials, our expert-engineered Muffle, Tube, Rotary, Vacuum, and CVD systems provide the temperature accuracy your lab demands.

Why choose KINTEK?

- Customizable Systems: Tailored to your specific austenitizing and quenching requirements.

- Expert R&D Support: Benefit from decades of manufacturing excellence.

- Reduced Rejection Rates: Achieve the perfect martensitic transformation without distortion.

Contact our technical team today to discover how our customizable high-temperature furnaces can optimize your manufacturing results!

Visual Guide

References

- Wenwen Xu, Chaobin Lai. Effect of Rare Earth Y on Microstructure and Mechanical Properties of High-Carbon Chromium Bearing Steel. DOI: 10.3390/met14040372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How are vacuum sintering furnaces utilized in electronic component manufacturing? Boost Purity and Performance

- How does argon help control aluminum volatilization in vacuum furnaces? Master Your Smelting Yields

- What makes vacuum furnaces more efficient compared to conventional furnaces? Unlock Superior Heat Treatment and Energy Savings

- What is the disadvantage of graphite furnace? Key Trade-offs for Ultra-Trace Analysis

- What is the necessity of vacuum drying equipment for ball-milled powders? Ensure Purity & Density in Ceramics

- How does the vacuum furnace improve the performance of heat-treated products? Achieve Superior Control and Quality

- How does vacuum brazing prevent oxidation and contamination? Achieve Clean, Strong Joints for Critical Applications

- Why is a vacuum drying oven necessary for chitosan and iron sludge particles? Expert Structural Preservation Guide