The necessity of utilizing vacuum drying equipment for ball-milled powders lies in its ability to facilitate rapid solvent evaporation at reduced temperatures. By lowering the ambient pressure, the system significantly depresses the boiling point of liquids, allowing for the removal of moisture and milling media without subjecting heat-sensitive powders to oxidation. This process is essential for ensuring the thorough removal of adsorbed volatiles that would otherwise cause structural defects, such as cracks or pores, during the final sintering phase.

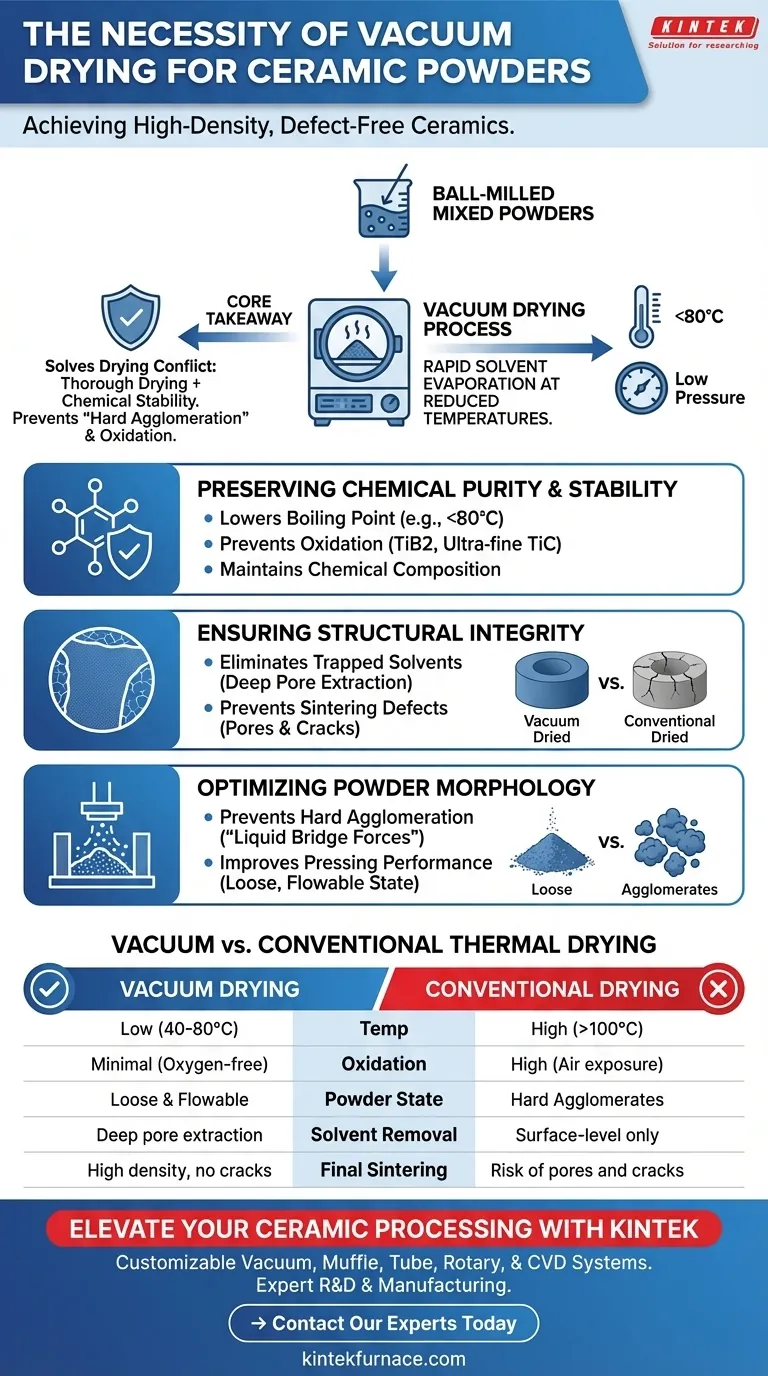

Core Takeaway Vacuum drying solves the conflict between thorough drying and chemical stability. It eliminates the "hard agglomeration" and oxidation associated with high-temperature drying, ensuring the powder retains the high surface activity and "loose" morphology required for high-density, defect-free ceramic manufacturing.

Preserving Chemical Purity and Stability

Lowering the Boiling Point

The primary mechanism of a vacuum dryer is the reduction of system pressure. This physical change drastically lowers the boiling temperature of solvents (such as ethanol or water) used in the wet ball-milling process.

Preventing Oxidation

Because evaporation occurs at lower temperatures (e.g., 60°C - 80°C), the risk of thermal oxidation is minimized. This is critical for active or oxygen-sensitive materials, such as TiB2 or ultra-fine titanium carbide, which can degrade or undergo phase changes in high-temperature air.

Maintaining Chemical Composition

Vacuum drying prevents hydrolysis and other chemical degradation pathways that occur in humid, high-heat environments. This ensures the precursor mixture maintains the exact chemical stoichiometry intended for the final product.

Ensuring Structural Integrity

Eliminating Deeply Trapped Solvents

Standard drying often fails to remove solvents trapped inside particle pores or agglomerates. Vacuum environments create a pressure differential that draws out trace residual solvents and adsorbed water from deep within the powder structure.

Preventing Sintering Defects

If solvents remain trapped in the powder, they will turn into gas during the high-temperature sintering process. This gas release creates pressure that leads to pores and cracks, compromising the density and mechanical strength of the ceramic. Vacuum drying effectively eliminates this risk at the source.

Optimizing Powder Morphology

Preventing Hard Agglomeration

High-temperature drying often causes "liquid bridge forces" between particles, leading to the formation of hard, dense clumps (agglomerates) that are difficult to break down. Vacuum drying removes moisture rapidly at low heat, preventing severe secondary agglomeration.

Improving Pressing Performance

By avoiding hard agglomerates, the dried powder remains in a "loose state." This flowability is vital for subsequent molding and pressing stages, ensuring uniform filling of molds and consistent density in the green body (the unfired ceramic object).

Understanding the Risks of Standard Thermal Drying

The Temperature Trade-off

In standard ovens, increasing the drying speed requires increasing the temperature. This creates a direct trade-off: faster drying leads to higher oxidation and grain growth. Vacuum drying bypasses this trade-off completely.

The Density Trap

Conventional drying may leave the surface of the powder dry while trapping moisture internally. While the powder may appear ready, this hidden moisture inevitably leads to lower material density and compromised structural integrity after firing.

Making the Right Choice for Your Goal

To apply this to your specific manufacturing context, consider your primary objective:

- If your primary focus is Material Purity: Use vacuum drying to process oxygen-sensitive powders (like TiB2 or TiC) at temperatures below 80°C to prevent surface oxidation.

- If your primary focus is High Density: Rely on the vacuum environment to extract trace solvents from within powder pores, eliminating the gas release that causes sintering cracks.

- If your primary focus is Process Efficiency: Utilize vacuum drying to maintain a loose, flowable powder structure, which simplifies the subsequent grinding and pressing operations.

Vacuum drying is not merely a dehydration step; it is a critical quality control measure that defines the final density and purity of high-performance ceramics.

Summary Table:

| Feature | Vacuum Drying | Conventional Thermal Drying |

|---|---|---|

| Drying Temp | Low (40°C - 80°C) | High (>100°C) |

| Oxidation Risk | Minimal (Oxygen-free) | High (Air exposure) |

| Powder State | Loose & Flowable | Hard Agglomerates |

| Solvent Removal | Deep pore extraction | Surface-level only |

| Final Sintering | High density, no cracks | Risk of pores and cracks |

Elevate Your Ceramic Processing with KINTEK

Don't let trapped moisture or oxidation compromise your material integrity. KINTEK provides industry-leading vacuum drying solutions and high-temperature lab furnaces tailored for advanced ceramic manufacturing. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet your unique research and production needs.

Ready to achieve superior powder morphology and defect-free sintering?

→ Contact Our Experts Today to Find Your Perfect Solution

Visual Guide

References

- I O Poenaru, V Puţan. Research Regarding Advanced Degassing of Steels for Manufacturing Automotive Components. DOI: 10.1088/1742-6596/3153/1/012016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How are vacuum experimental furnaces used in research and laboratory settings? Unlock Precision in Materials Science

- How do miniature vacuum furnaces ensure image stability? Advanced Engineering for High-Resolution Ceramic Imaging

- What is the primary purpose of 340°C in-situ annealing on niobium cavities? Boost Quench Field Strength Effectively

- How are vacuum furnaces utilized in additive manufacturing post-processing? Unlock High-Performance Metal Parts

- What are the common types of materials used for constructing heating elements in electrically heated vacuum furnaces? Choose the Right Material for Your Process

- What is the purpose of a vacuum furnace? Achieve Superior Material Quality and Purity

- What are the advantages of using a vacuum sintering furnace for MgO? Unlock Density and Optical Clarity

- Why is vacuum degassing equipment utilized in the preparation of low-alloy fire-resistant steel? | KINTEK Solutions