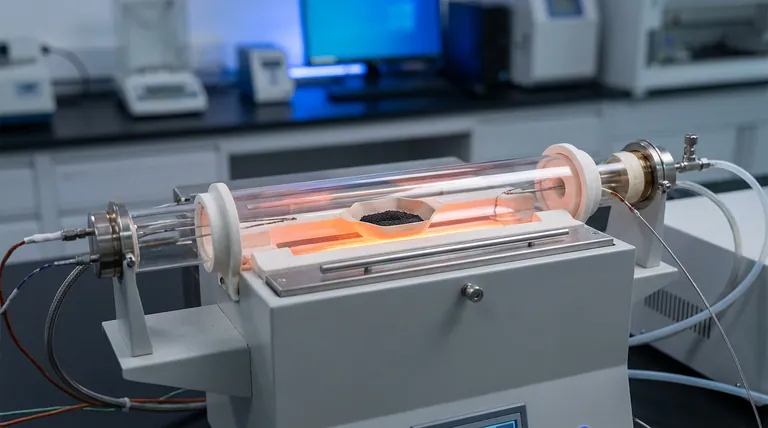

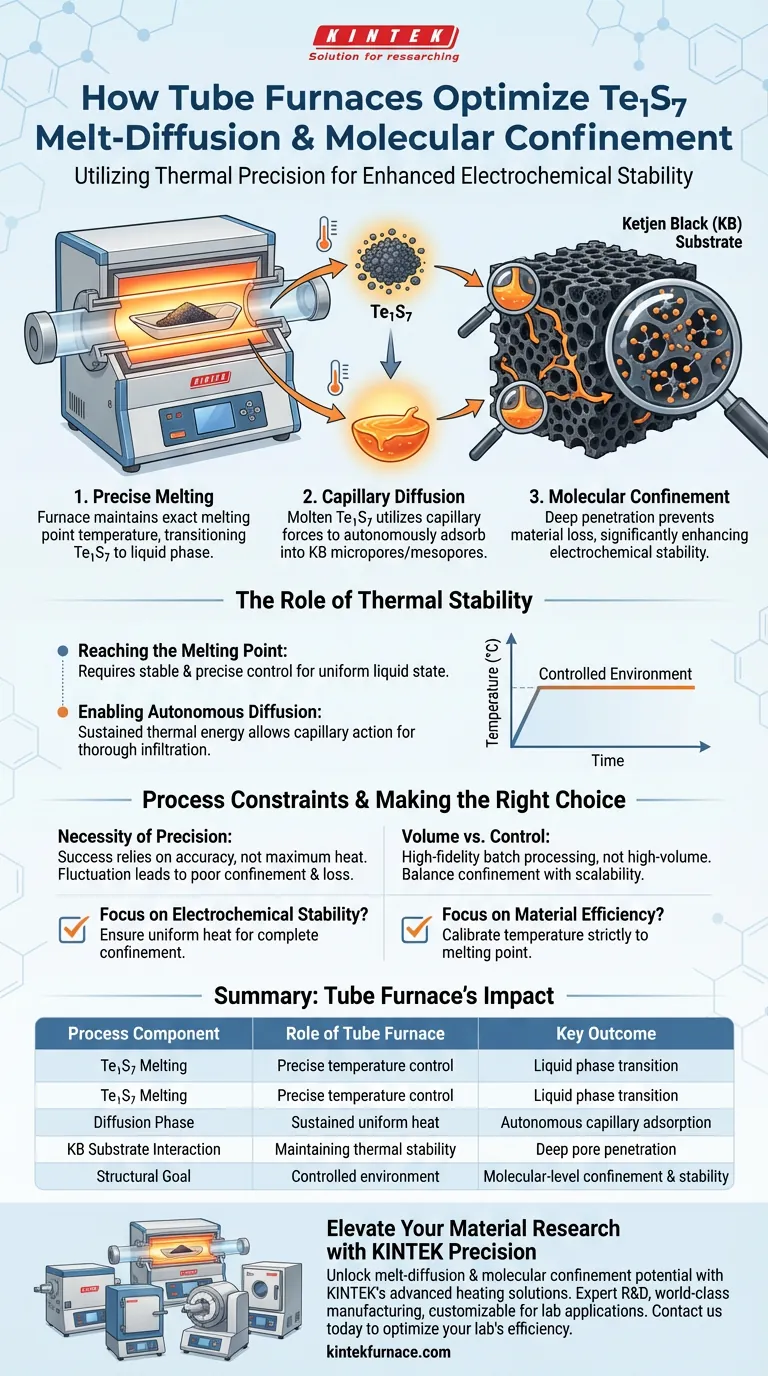

The melt-diffusion process relies fundamentally on the thermal precision of the tube furnace. This equipment creates a controlled environment where the temperature is maintained exactly at the melting point of Te1S7, transitioning it into a liquid state capable of physical migration. This specific thermal state allows the active material to infiltrate the porous structure of carbon substrates through capillary action.

Core Takeaway The tube furnace is not merely a heat source; it is a precision tool used to liquefy Te1S7, enabling capillary forces to draw the material into carbon micropores. This results in molecular-level confinement that significantly enhances the electrochemical stability of the final composite.

The Role of Thermal Stability

Reaching the Melting Point

The primary function of the heating equipment is to provide stable and precise temperature control.

The process requires heating the Te1S7 composite exactly to its melting point.

Without the uniform heat distribution provided by a tube furnace, the material might melt unevenly or fail to reach the liquid state necessary for diffusion.

Enabling Autonomous Diffusion

Once the Te1S7 becomes molten, the external energy provided by the furnace facilitates a physical transformation.

The liquid active material utilizes capillary forces to move without mechanical assistance.

This allows the Te1S7 to autonomously adsorb onto the surface of the carbon substrate.

Interaction with Carbon Substrates

Penetrating Ketjen Black (KB)

The process is specifically designed to exploit the structure of carbon materials like Ketjen Black (KB).

The molten Te1S7 penetrates deep into the substrate's microporous and mesoporous structures.

The tube furnace maintains the thermal conditions long enough for this thorough infiltration to occur.

Achieving Molecular Confinement

The goal of this heating process is molecular-level confinement.

By locking the active material inside the carbon pores, the process prevents material loss during operation.

This structural integration is the key factor in enhancing the electrochemical stability of the resulting composite material.

Understanding the Process Constraints

The Necessity of Precision

While tube furnaces—including vertical variations—are capable of reaching very high temperatures, the success of this process relies on accuracy, not just maximum heat.

If the temperature fluctuates significantly, the Te1S7 may not fully liquefy or could degrade before infiltrating the pores.

Inadequate thermal control results in poor confinement, leading to material loss and reduced performance.

Volume vs. Control

Tube furnaces excel at creating a controlled atmosphere for research and material testing.

However, they are typically batch-processing tools designed for high fidelity rather than high-volume throughput.

Users must balance the need for this precise molecular confinement with the scalability limits of the equipment.

Making the Right Choice for Your Goal

To maximize the effectiveness of the melt-diffusion process, align your equipment settings with your specific objectives:

- If your primary focus is Electrochemical Stability: Ensure your furnace provides uniform heat distribution to guarantee complete molecular confinement within the micropores.

- If your primary focus is Material Efficiency: Calibrate the temperature strictly to the melting point of Te1S7 to prevent vaporization or degradation of the active material.

Precision in heating is the catalyst that transforms raw materials into a highly stable, structurally integrated composite.

Summary Table:

| Process Component | Role of Tube Furnace | Key Outcome |

|---|---|---|

| Te1S7 Melting | Precise temperature control to reach exact melting point | Liquid phase transition for migration |

| Diffusion Phase | Sustained uniform heat distribution | Autonomous adsorption via capillary forces |

| KB Substrate Interaction | Maintaining thermal stability over time | Deep penetration into micro/mesopores |

| Structural Goal | Controlled environment for bonding | Molecular-level confinement & stability |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your melt-diffusion and molecular confinement processes with KINTEK’s advanced heating solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous thermal stability requirements of your specific lab applications.

Whether you are working with Te1S7 composites or advanced carbon substrates, our furnaces deliver the uniform temperature control essential for electrochemical stability. Contact us today to optimize your lab's efficiency and discover the difference of precision engineering.

Visual Guide

References

- Yue Zhang, Jian Liu. A Tellurium‐Boosted High‐Areal‐Capacity Zinc‐Sulfur Battery. DOI: 10.1002/advs.202308580

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does a tube furnace generate high temperatures? Efficient, Precise Heating for Your Lab

- Why is a vacuum-sealed quartz tube necessary for LaMg6Ga6S16 synthesis? Ensure Purity in Sulfide Production

- What is the function of a vacuum tube furnace in NbC-Cr7C3@graphene/Fe synthesis? Expert Guide to In-Situ Synthesis

- Why is precise atmosphere control necessary in a laboratory tube furnace for Ni-ZIF-8 to Ni-N-C conversion?

- What are the primary applications of vacuum tube furnaces in materials science? Unlock Precision in Material Synthesis and Heat Treatment

- What is the purpose of pre-treating sapphire substrates in a tube furnace? Optimize Your Epitaxial Growth Foundation

- How does a tube atmosphere furnace facilitate local CVD during PAN fiber carbonization? Master In-Situ CNT Growth

- What is the necessity of using high-purity argon (Ar) gas in a tube furnace for Sb sulfurization?