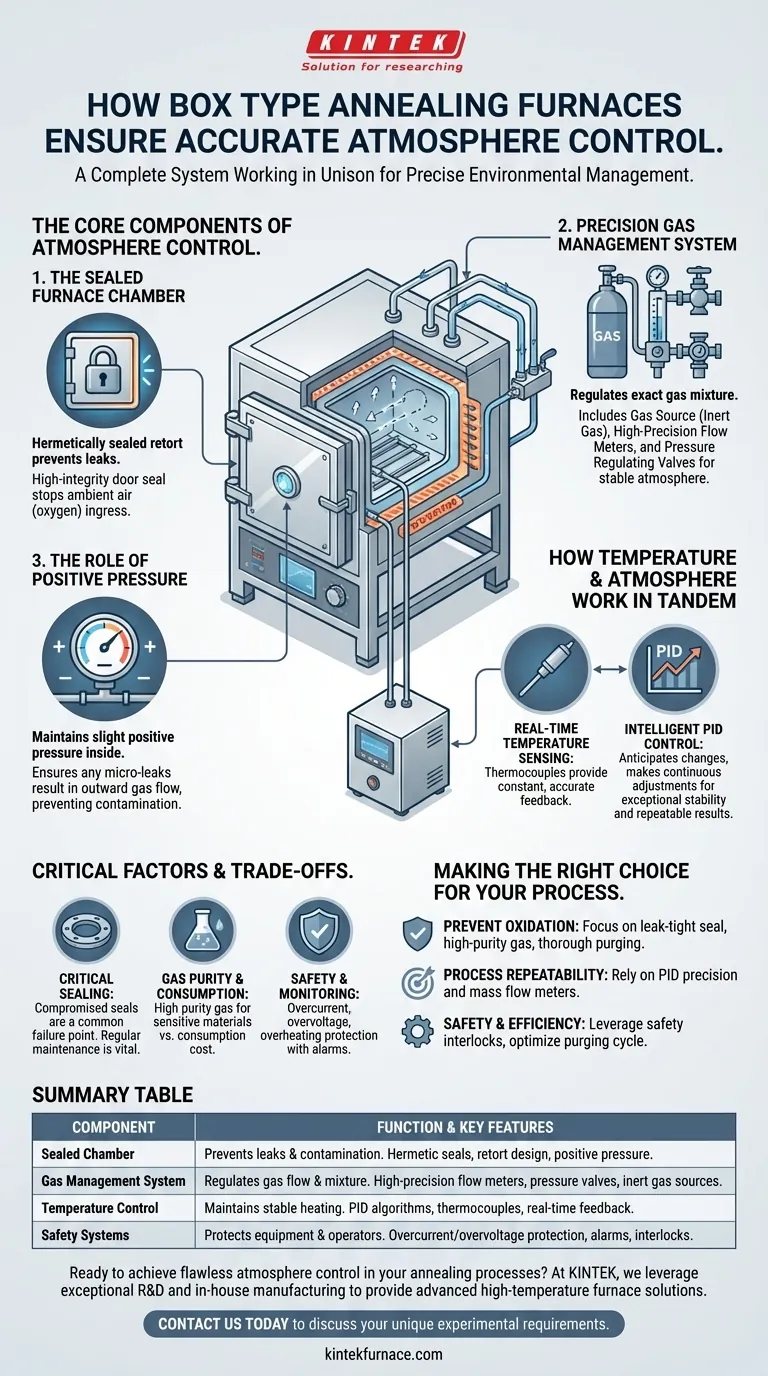

Accurate atmosphere control in a box type annealing furnace is not the result of a single component, but a complete system working in unison. This system ensures a specific, stable gas environment by precisely managing the gas entering the furnace, containing it within a perfectly sealed chamber, and preventing contamination from outside air. This allows for high-temperature processes, like annealing, to occur without unwanted chemical reactions such as oxidation.

The core challenge of atmosphere control isn't just introducing a specific gas; it's about creating and maintaining a chemically pure and uniform environment. This is achieved by systematically purging ambient air, precisely regulating gas flow, and ensuring the furnace chamber is hermetically sealed against leaks.

The Core Components of Atmosphere Control

A reliable atmosphere furnace operates on a few key principles, each managed by a dedicated subsystem. Understanding these components reveals how the furnace achieves such precise environmental control.

The Sealed Furnace Chamber

The first and most critical element is the physical containment. The furnace body, often containing an inner chamber called a retort, is designed to be a completely sealed vessel.

A high-integrity seal, especially around the furnace door, is non-negotiable. This seal prevents the controlled atmosphere from leaking out and, more importantly, stops ambient air (containing oxygen) from leaking in.

The Precision Gas Management System

This system is the heart of atmosphere regulation. It consists of several components working together to deliver the exact gas mixture required for the process.

The system begins with a gas source, typically a cylinder of inert gas like nitrogen or argon. From there, high-precision gas flow meters measure the exact volume of gas being introduced into the chamber.

Finally, pressure regulating valves fine-tune the flow rate and pressure. This allows the operator to control not only the type of gas but also its concentration and flow, ensuring a stable and uniform atmosphere is established and maintained.

The Role of Positive Pressure

To further guarantee against contamination, these furnaces operate by maintaining a slight positive pressure inside the chamber.

By ensuring the internal pressure is always slightly higher than the outside atmospheric pressure, any potential micro-leaks will result in the internal gas flowing out, rather than external air flowing in. This is a simple but highly effective principle for preventing oxidation.

How Temperature and Atmosphere Work in Tandem

Atmosphere control does not work in a vacuum; it is critically dependent on the furnace's temperature control system. The chemical reactions that the atmosphere is meant to control are highly sensitive to temperature.

Real-Time Temperature Sensing

High-precision sensors, such as thermocouples, are placed inside the furnace to measure the temperature in real time. These sensors provide constant, accurate feedback to the control system.

Intelligent PID Control

This temperature data is fed to an intelligent controller that uses a PID (Proportional-Integral-Derivative) algorithm. Instead of simply turning the heat on or off, a PID controller anticipates temperature changes and makes continuous, minute adjustments to the heating power.

This advanced control maintains the temperature with exceptional stability, preventing overshooting or undershooting the target setpoint, which is crucial for repeatable metallurgical results.

Understanding the Trade-offs and Critical Factors

While highly effective, achieving perfect atmosphere control requires attention to detail and an understanding of potential failure points.

The Critical Importance of Sealing

The single most common point of failure in atmosphere control is a compromised seal. Gaskets and door seals wear over time and must be inspected and maintained regularly. A small, undetected leak can ruin a process by allowing oxygen to enter the chamber at high temperatures.

Gas Purity and Consumption

The purity of your source gas directly impacts the purity of the furnace atmosphere. For highly sensitive materials, using a high-purity grade gas is essential. There is also a trade-off between gas flow rate—used to purge the chamber of air—and the cost of gas consumption.

Safety and System Monitoring

These furnaces are equipped with multiple safety protection devices, including overcurrent, overvoltage, and overheating protection. In an abnormal event, these systems will automatically cut power and trigger an alarm, protecting both the equipment and the operator.

Making the Right Choice for Your Process

The way you operate the furnace depends entirely on your end goal. The system's precision allows you to tailor the process to meet specific quality and safety standards.

- If your primary focus is preventing any and all oxidation: Your priority is a verified leak-tight seal, the use of high-purity inert gas, and a thorough purging cycle to remove all residual oxygen before heating begins.

- If your primary focus is process repeatability: You must rely on the precision of the PID temperature controller and the digital mass flow meters to ensure every run is identical in its thermal and atmospheric profile.

- If your primary focus is safety and efficiency: Leverage the furnace's integrated safety interlocks and monitoring systems, and optimize your purging cycle time to balance throughput with gas consumption.

Ultimately, mastering your heat treatment process comes from understanding that the furnace is a complete environmental control system, not just a simple heater.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Sealed Chamber | Prevents gas leaks and contamination | Hermetic seals, retort design, positive pressure |

| Gas Management System | Regulates gas flow and mixture | High-precision flow meters, pressure valves, inert gas sources |

| Temperature Control | Maintains stable heating | PID algorithms, thermocouples, real-time feedback |

| Safety Systems | Protects equipment and operators | Overcurrent/overvoltage protection, alarms, interlocks |

Ready to achieve flawless atmosphere control in your annealing processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your lab's efficiency and results!

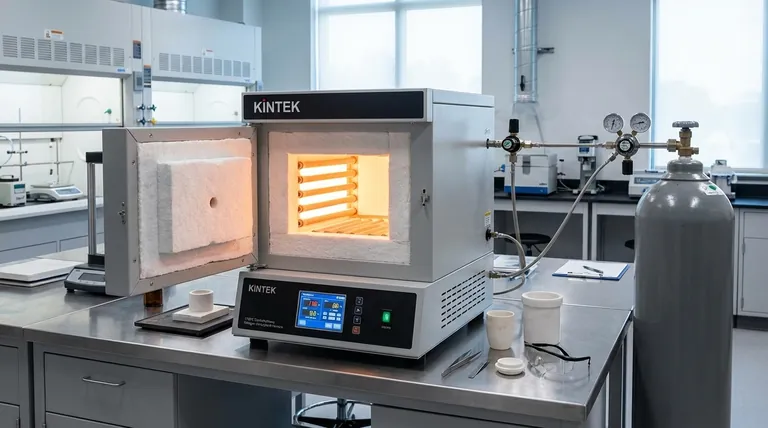

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas