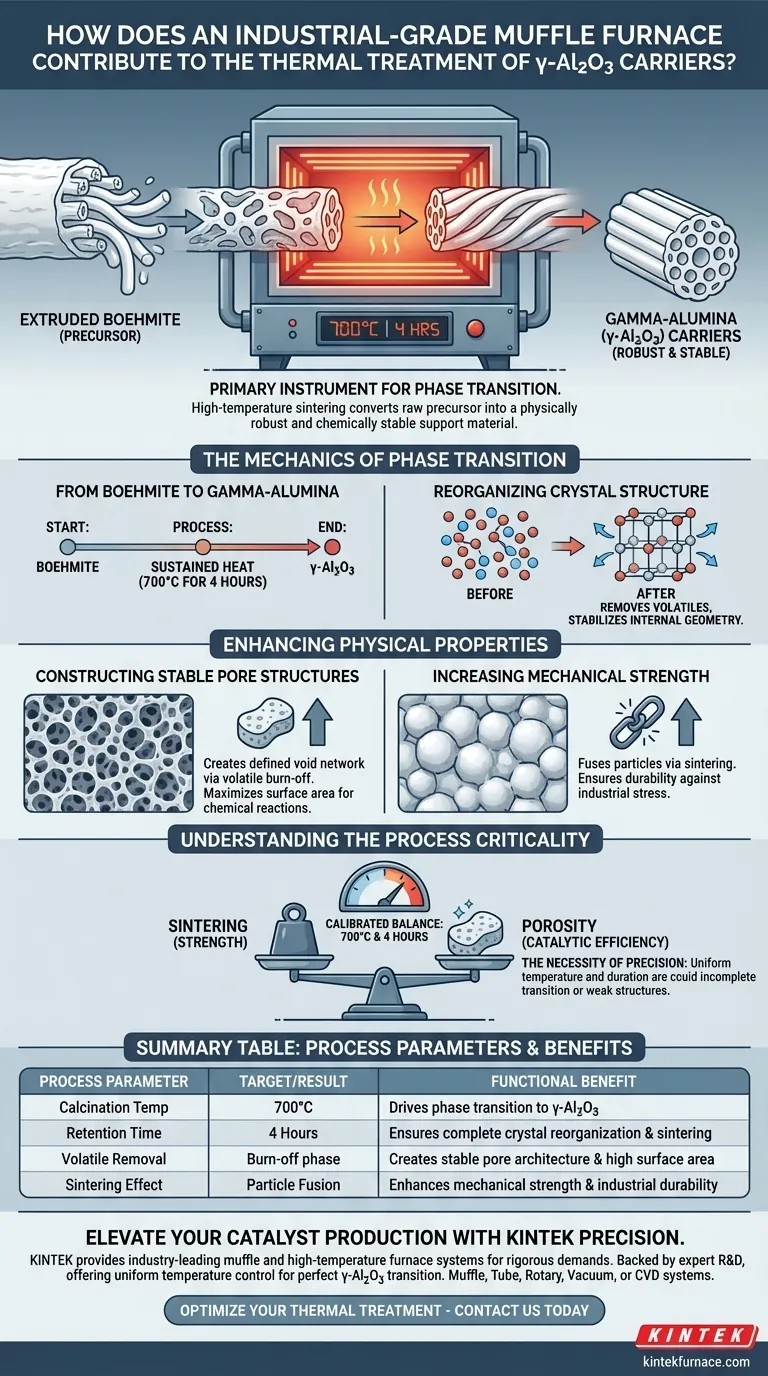

An industrial-grade muffle furnace is the primary instrument used to drive the phase transition of extruded boehmite into gamma-alumina ($\gamma\text{-Al}_2\text{O}_3$) carriers. By subjecting the material to a precise calcination process at 700°C for approximately four hours, the furnace facilitates high-temperature sintering. This treatment is essential for converting the raw precursor into a physically robust and chemically stable support material.

The muffle furnace does more than simply dry the material; it fundamentally reorganizes the crystal structure through sintering. This process creates the mechanical durability and stable pore architecture necessary for the carrier to function effectively in catalytic environments.

The Mechanics of Phase Transition

From Boehmite to Gamma-Alumina

The core function of the muffle furnace in this context is to enable calcination. The raw material enters the furnace as extruded boehmite.

Through sustained exposure to high heat—specifically 700°C for a duration of 4 hours—the boehmite undergoes a chemical and physical transformation. This specific thermal profile ensures the complete conversion into the desired $\gamma\text{-Al}_2\text{O}_3$ phase.

Reorganizing Crystal Structure

During this heating process, the furnace environment allows for the removal of volatiles trapped within the extruded material.

As these volatiles are expelled, the internal crystal lattice shifts. The muffle furnace provides the consistent thermal energy required to reorganize these atoms, stabilizing the material's internal geometry.

Enhancing Physical Properties

Constructing Stable Pore Structures

For a carrier to be effective in catalysis, it requires a specific network of voids, or pores.

The muffle furnace creates these structures by removing volatile components during the sintering phase. This "burn-off" leaves behind a stable, defined pore structure that maximizes the surface area available for chemical reactions.

Increasing Mechanical Strength

A raw boehmite extrudate lacks the physical toughness required for industrial reactors.

The high-temperature sintering process fuses the material particles together. This enhances the overall mechanical strength of the carrier, ensuring it can withstand the physical stresses of operation without crumbling or degrading.

Understanding the Process Criticality

The Necessity of Precision

The transition to $\gamma\text{-Al}_2\text{O}_3$ is highly dependent on adhering to specific process parameters.

An industrial-grade furnace is required because it can maintain the rigorous 700°C standard uniformly. Fluctuations in temperature or insufficient heating time (less than the prescribed 4 hours) could lead to incomplete phase transitions or weak structural integrity.

Balancing Sintering and Porosity

There is a delicate relationship between hardening the material and maintaining its porosity.

The process aims to sinter the material enough to grant it strength, but not so much that the pores collapse. The specific protocol of 700°C for 4 hours is the calibrated balance point that achieves both durability and catalytic utility.

Making the Right Choice for Your Goal

To maximize the effectiveness of your thermal treatment strategy, consider your specific performance targets.

- If your primary focus is mechanical durability: Ensure the sintering duration reaches the full 4-hour benchmark to maximize particle fusion and structural hardness.

- If your primary focus is catalytic efficiency: Prioritize precise temperature control at 700°C to guarantee the removal of volatiles and the formation of stable pore networks.

The muffle furnace is not just a heating element; it is a precision tool that defines the structural and chemical identity of your catalyst carrier.

Summary Table:

| Process Parameter | Target/Result | Functional Benefit |

|---|---|---|

| Calcination Temp | 700°C | Drives phase transition from boehmite to $\gamma$-Al2O3 |

| Retention Time | 4 Hours | Ensures complete crystal reorganization and sintering |

| Volatile Removal | Burn-off phase | Creates stable pore architecture and high surface area |

| Sintering Effect | Particle Fusion | Enhances mechanical strength and industrial durability |

Elevate Your Catalyst Production with KINTEK Precision

High-performance catalyst carriers require absolute thermal precision. KINTEK provides industry-leading muffle and high-temperature furnace systems designed to meet the rigorous demands of chemical research and industrial manufacturing. Backed by expert R&D, our furnaces offer the uniform temperature control and customizable heating profiles necessary for the perfect $\gamma$-Al2O3 phase transition.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, KINTEK delivers reliable, customizable solutions tailored to your unique lab or production needs.

Ready to optimize your thermal treatment? Contact us today to speak with an expert.

Visual Guide

References

- Eun-Han Lee, Shin‐Kun Ryi. Quick drying process: a promising strategy for preparing an egg-shell-type Cu/γ-Al <sub>2</sub> O <sub>3</sub> catalyst for direct N <sub>2</sub> O decomposition. DOI: 10.1039/d4ta07764d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What should be considered regarding the controller when purchasing a muffle furnace? Choose the Right Controller for Precision

- Why is a high-temperature muffle furnace utilized for g-C3N4 nanosheet synthesis? Master Two-Step Thermal Exfoliation

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- What features might advanced muffle furnace models include? Enhance Precision, Safety, and Efficiency

- What is important about chamber size in muffle furnaces? Ensure Accurate Heating with the Right Zone

- How does the design of muffle furnaces contribute to the longevity of heating elements? Extend Lifespan with Protective Isolation

- How is a muffle furnace applied in the food industry? Essential for Ash and Moisture Analysis

- What is a muffle furnace and what are its primary functions? Unlock Contamination-Free High-Temperature Processing