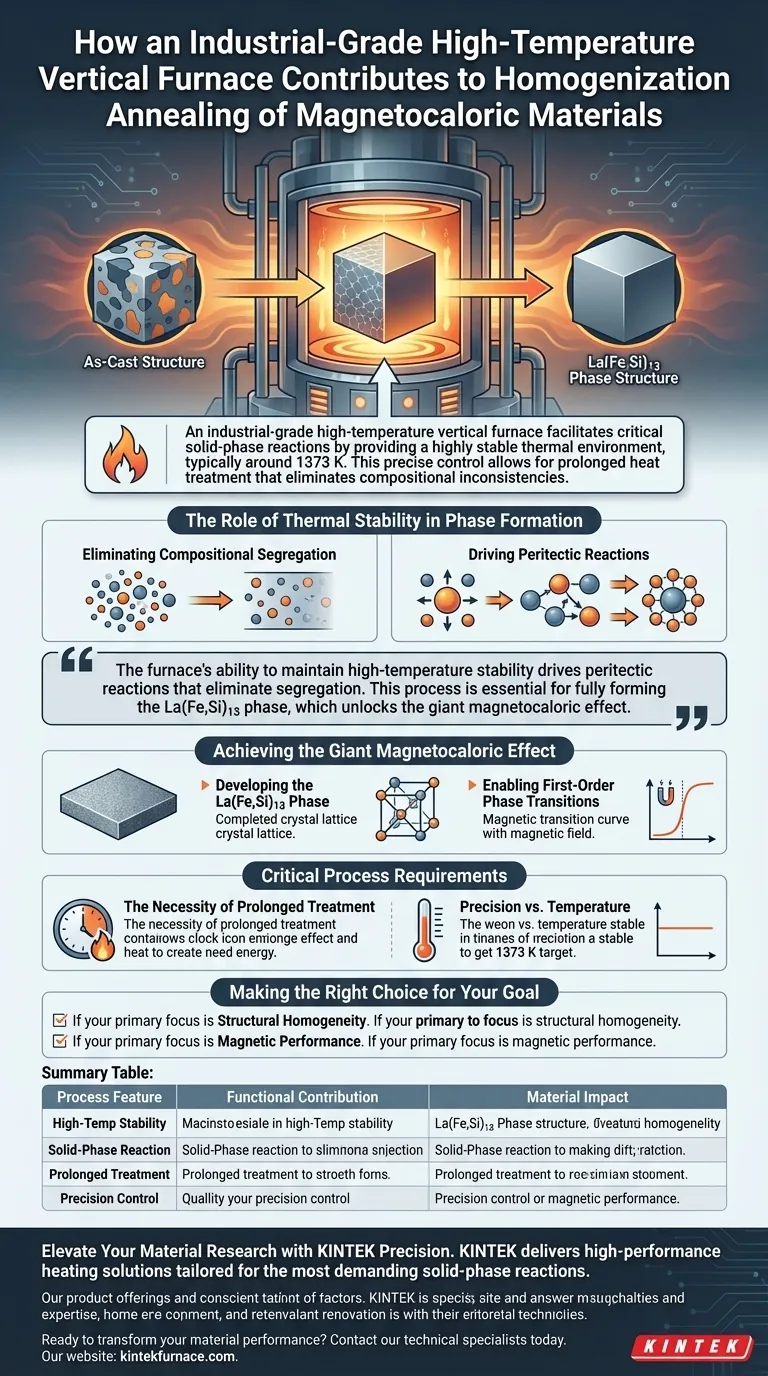

An industrial-grade high-temperature vertical furnace facilitates critical solid-phase reactions by providing a highly stable thermal environment, typically around 1373 K. This precise control allows for prolonged heat treatment that eliminates compositional inconsistencies found in raw cast materials, ensuring the material develops the specific internal structure required for high performance.

The furnace’s ability to maintain high-temperature stability drives peritectic reactions that eliminate segregation. This process is essential for fully forming the La(Fe,Si)13 phase, which unlocks the giant magnetocaloric effect.

The Role of Thermal Stability in Phase Formation

Eliminating Compositional Segregation

Raw alloy samples typically exhibit an "as-cast" structure. In this state, the material suffers from compositional segregation, meaning the chemical elements are not distributed evenly throughout the solid.

The vertical furnace combats this by providing a consistent thermal soak. This high-temperature environment promotes diffusion, effectively smoothing out these inconsistencies.

Driving Peritectic Reactions

The homogenization process relies on solid-phase reactions. These are complex atomic rearrangements that require sustained energy.

By maintaining a temperature of approximately 1373 K, the furnace creates the necessary conditions for these reactions to proceed efficiently. This stability is crucial for converting the initial alloy components into the desired final structure.

Achieving the Giant Magnetocaloric Effect

Developing the La(Fe,Si)13 Phase

The ultimate goal of using this furnace is the full development of the La(Fe,Si)13 phase. This specific crystal structure does not form instantly upon casting.

It requires the prolonged heat treatment provided by the vertical furnace to grow. The furnace ensures that the peritectic reactions required to create this phase are carried through to completion.

Enabling First-Order Phase Transitions

The physical properties of the material depend entirely on the success of the annealing process. To achieve the giant magnetocaloric effect, the material must be capable of a first-order phase transition.

This transition is a direct result of the structural purity achieved in the furnace. Without the elimination of segregation and the formation of the La(Fe,Si)13 phase, this magnetic characteristic would be unattainable.

Critical Process Requirements

The Necessity of Prolonged Treatment

Homogenization is not instantaneous. The text emphasizes that prolonged heat treatment is required to achieve the desired results.

Operators must understand that the furnace is not just about reaching a peak temperature, but sustaining it. Short-cutting this duration risks leaving unreacted material and segregation within the sample.

Precision vs. Temperature

The process targets a specific thermal point (1373 K). This implies that thermal precision is as important as heat generation.

Fluctuations in temperature could interrupt the solid-phase reactions. The industrial grade of the vertical furnace is valuable specifically because it stabilizes this environment against external variables.

Making the Right Choice for Your Goal

To maximize the effectiveness of your annealing process, align your furnace operations with your specific material objectives:

- If your primary focus is Structural Homogeneity: Ensure the furnace is calibrated to maintain 1373 K with minimal fluctuation to effectively eliminate compositional segregation.

- If your primary focus is Magnetic Performance: Prioritize prolonged heat treatment cycles to ensure the peritectic reactions are complete, fully developing the La(Fe,Si)13 phase.

By leveraging the stability of a vertical furnace, you transform inconsistent cast alloys into high-performance magnetocaloric materials.

Summary Table:

| Process Feature | Functional Contribution | Material Impact |

|---|---|---|

| High-Temp Stability | Maintains 1373 K thermal soak | Eliminates compositional segregation |

| Solid-Phase Reaction | Drives atomic diffusion & rearrangement | Drives peritectic reaction completion |

| Prolonged Treatment | Sustained energy input | Ensures full La(Fe,Si)13 phase growth |

| Precision Control | Minimizes thermal fluctuations | Enables giant magnetocaloric effect |

Elevate Your Material Research with KINTEK Precision

Achieving the giant magnetocaloric effect requires the uncompromising thermal stability that only expert engineering can provide. KINTEK delivers high-performance heating solutions tailored for the most demanding solid-phase reactions.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique homogenization and annealing needs. Whether you are developing advanced alloys or refining magnetic phase transitions, our equipment ensures the precision your research deserves.

Ready to transform your material performance? Contact our technical specialists today to find your ideal furnace solution.

Visual Guide

References

- Fengqi Zhang, Yang Ren. Engineering Light‐Element Modified LaFe <sub>11.6</sub> Si <sub>1.4</sub> Compounds Enables Tunable Giant Magnetocaloric Effect. DOI: 10.1002/advs.202416288

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How is furnace brazing applied in research and development? A Precision Tool for Material Science & Prototyping

- Why is an ultra-high vacuum (UHV) environment necessary for PES measurements of 1T-TaS2? Ensure Data Integrity

- Why use vacuum and argon in pulse solidification? Protect your Aluminum-Silicon alloys from oxidation and contamination

- Why is a high-performance vacuum system critical for Gallium Sulfide crystal sealing? Ensure 10^-6 Torr Purity

- What are the advantages of vacuum furnaces? Achieve Pristine Material Processing and Control

- How does a high-temperature vacuum furnace convert PDA into nitrogen-doped carbon shells? Master Carbonization Control

- Why is a vacuum high-temperature furnace necessary for Cu-Cr-Zr-La alloy ingots? Ensure Material Uniformity

- How do the radiant heating and controlled cooling functions of a vacuum brazing furnace benefit Kovar-to-SS joints?