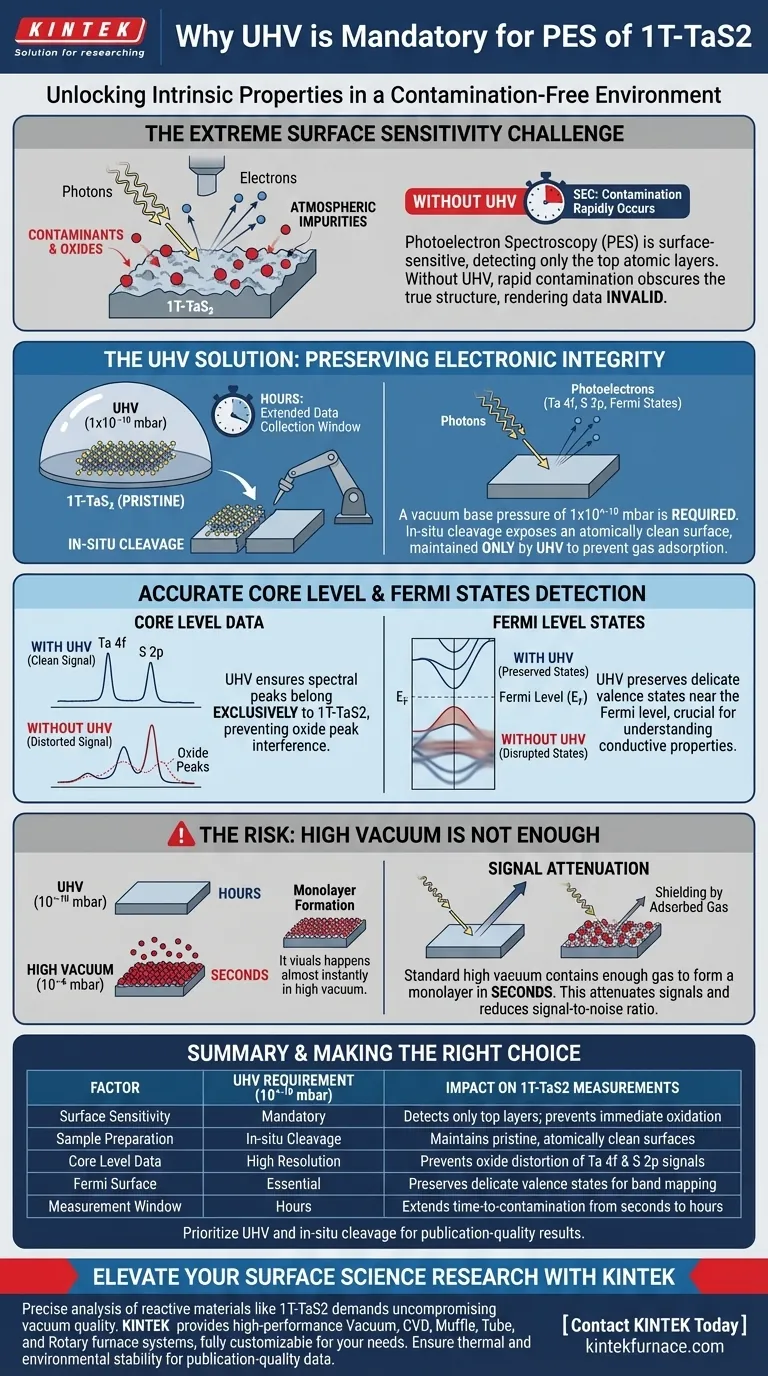

An ultra-high vacuum (UHV) environment is strictly mandatory for conducting reliable Photoelectron Spectroscopy (PES) measurements on 1T-TaS2. Because this material is extremely sensitive to surface contamination, a vacuum base pressure as low as 1x10^-10 mbar is required to prevent immediate oxidation and the adsorption of atmospheric impurities following sample preparation.

Photoelectron Spectroscopy is inherently surface-sensitive, detecting electrons from only the top few atomic layers. Without UHV conditions, rapid surface contamination obscures the true electronic structure of 1T-TaS2, rendering the data regarding core levels and Fermi surface states scientifically invalid.

The Physical Necessity of UHV

Combating Extreme Surface Sensitivity

1T-TaS2 is highly reactive when exposed to standard atmospheric elements.

The material has a strong tendency to oxidize or adsorb impurities from the surrounding environment. If the vacuum pressure is not sufficiently low, these chemical changes occur almost instantly on the sample surface.

The Role of In-Situ Cleavage

To access the intrinsic properties of the material, 1T-TaS2 samples are typically "cleaved" (split open) directly inside the measurement chamber.

This process exposes a pristine, atomically clean surface. A UHV environment is the only way to maintain this pristine state long enough to perform the measurement before gas molecules re-coat the surface.

Preserving Electronic Data Integrity

Accurate Core Level Detection

The primary goal of PES in this context is to analyze specific elemental signatures, particularly the Tantalum (Ta) 4f and Sulfur (S) 2p core levels.

Contaminants on the surface can chemically alter these states or bury the signal. UHV ensures that the spectral peaks you observe belong exclusively to the 1T-TaS2 crystal lattice, not to surface oxides.

Capturing Fermi Level States

The electronic states near the Fermi level are critical for understanding the conductive and electronic properties of 1T-TaS2.

These states are the most delicate and easily disrupted by surface interactions. An ultra-clean environment preserves these subtle electronic features, allowing for an accurate reconstruction of the material's band structure.

Understanding the Risks of Compromise

The "High Vacuum" Trap

It is a common misconception that a standard "high vacuum" (e.g., 10^-6 or 10^-7 mbar) is sufficient for solid-state analysis.

For reactive materials like 1T-TaS2, a standard high vacuum still contains enough gas molecules to form a monolayer of contamination in mere seconds. Only the 10^-10 mbar regime extends this "time to contamination" to hours, providing a viable window for data collection.

Signal Attenuation

Even if the material does not chemically react with the background gas, physical adsorption can occur.

A layer of adsorbed gas acts as a shield, attenuating the escape of photoelectrons. This reduces the signal-to-noise ratio and can lead to misinterpretation of relative peak intensities.

Making the Right Choice for Your Experiment

To ensure your spectral data is publication-quality and physically meaningful, you must prioritize vacuum quality based on your specific analytical goals.

- If your primary focus is Core Level Analysis (Ta 4f, S 2p): Ensure your system reaches 1x10^-10 mbar to prevent oxide peaks from overlapping with or distorting your elemental signals.

- If your primary focus is Fermi Surface Mapping: Prioritize in-situ cleavage capabilities combined with UHV to preserve the delicate valence states that define the material's electronic behavior.

Ultimately, the validity of your 1T-TaS2 analysis depends entirely on the cleanliness of the interface between your sample and the vacuum.

Summary Table:

| Factor | UHV Requirement (10^-10 mbar) | Impact on 1T-TaS2 Measurements |

|---|---|---|

| Surface Sensitivity | Mandatory | Detects only top atomic layers; prevents immediate oxidation |

| Sample Preparation | In-situ Cleavage | Maintains pristine, atomically clean surfaces post-cleavage |

| Core Level Data | High Resolution | Prevents oxide peaks from distorting Ta 4f and S 2p signals |

| Fermi Surface | Essential | Preserves delicate valence states for accurate band mapping |

| Measurement Window | Hours | Extends time-to-contamination from seconds to hours |

Elevate Your Surface Science Research with KINTEK

Precise analysis of reactive materials like 1T-TaS2 demands uncompromising vacuum quality. Backed by expert R&D and manufacturing, KINTEK provides high-performance lab high-temp furnaces—including Vacuum, CVD, Muffle, Tube, and Rotary systems—all fully customizable to meet your unique experimental needs.

Whether you are conducting core level analysis or mapping Fermi surfaces, our equipment ensures the thermal and environmental stability required for publication-quality results. Contact KINTEK today to discuss your custom furnace requirements and discover how our specialized solutions can enhance your laboratory's efficiency and data accuracy.

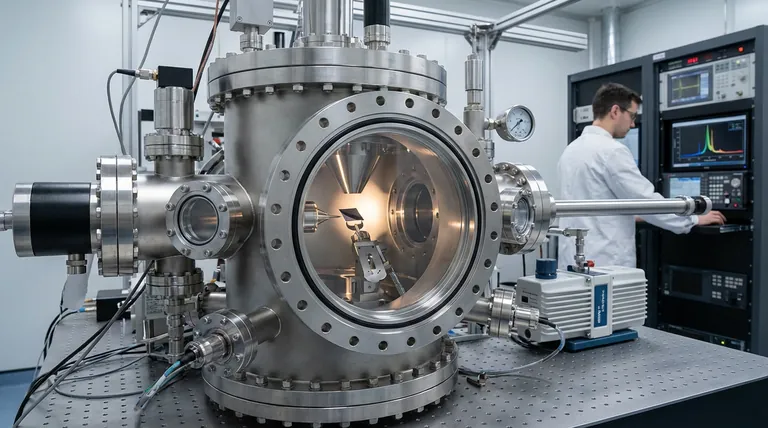

Visual Guide

References

- Yihao Wang, Liang Cao. Dualistic insulator states in 1T-TaS2 crystals. DOI: 10.1038/s41467-024-47728-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

- Ultra High Vacuum CF Observation Window Flange with High Borosilicate Glass Sight Glass

- Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

People Also Ask

- What is the purpose of using a high-vacuum system and annealing furnace for Mn–Ni–Fe–Si alloys? Unlock Data Accuracy

- What are the key components of a vacuum pressure sintering furnace? Essential Systems for High-Performance Materials

- What is the significance of using a vacuum drying oven for silicon electrode slurries? Achieve Robust Battery Integrity

- What are the advantages of using an industrial vacuum oven for biomass powders? Maximize Quality & Chemical Stability

- What is the purpose of using a vacuum oven for h-NCM(OH)2? Optimize Your Cathode Material Research

- How do modern vacuum furnaces improve energy efficiency? Achieve Superior Thermal Processing with Lower Energy Costs

- What are the technical advantages of vacuum Spark Plasma Sintering (SPS) systems? Advanced SiC Ceramic Densification

- What is vacuum carburizing or low pressure carburizing (LPC)? Unlock Precision Case Hardening for Steel