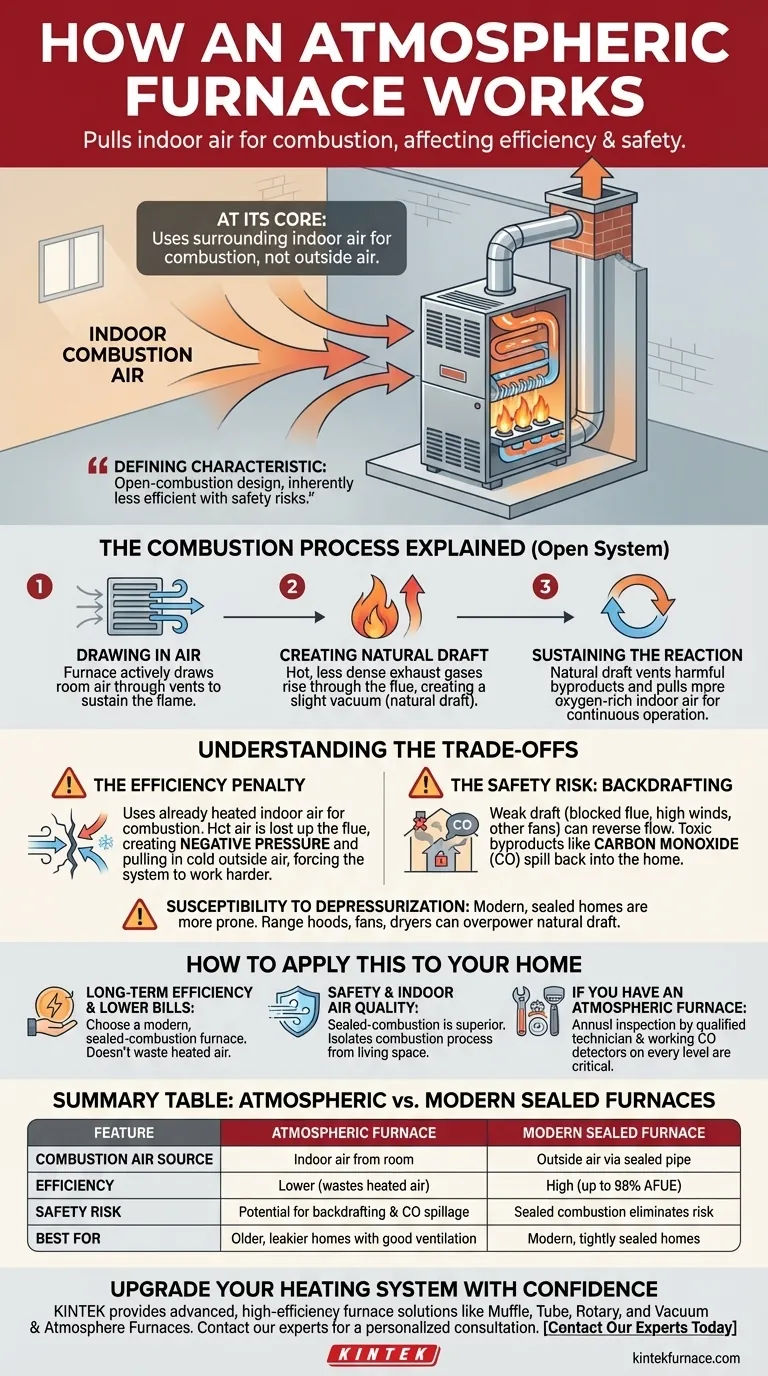

At its core, an atmospheric furnace works by pulling air directly from your home to fuel its combustion process. Unlike modern sealed units that draw air from the outside, these furnaces use the air in their immediate surroundings—be it a basement, closet, or utility room—to mix with natural gas and create heat. This fundamental design choice has significant implications for efficiency and safety.

The defining characteristic of an atmospheric furnace is its use of indoor air for combustion. While simple, this open-combustion design makes it inherently less efficient and introduces safety risks, like backdrafting, that are eliminated in modern sealed-combustion systems.

The Combustion Process Explained

An atmospheric furnace, also known as a natural draft furnace, relies on basic principles of physics to operate. It is an "open" system, meaning its combustion chamber is not sealed off from the surrounding indoor environment.

Step 1: Drawing in Combustion Air

The furnace features vents or a grille on its cabinet. It actively draws air from the room it occupies through these openings. This is the air that will be used to sustain the flame at the burners.

Step 2: Creating a Natural Draft

When the furnace burners ignite, they produce hot exhaust gases. Because these gases are much hotter and less dense than the surrounding air, they naturally rise up through a metal flue pipe or chimney. This upward movement creates a slight vacuum, a phenomenon known as natural draft or the "stack effect."

Step 3: Sustaining the Reaction

This natural draft is critical. It not only vents harmful byproducts like carbon monoxide but also helps pull more oxygen-rich air from the room into the combustion chamber, sustaining the heating process in a continuous cycle.

Understanding the Trade-offs

The simplicity of the atmospheric design is also its greatest weakness. Relying on indoor air and natural draft creates significant disadvantages compared to modern heating technology.

The Efficiency Penalty

Atmospheric furnaces use air that you have already paid to heat for their combustion process. This heated air is then immediately sent up the flue as exhaust. This process creates negative pressure inside your home, causing cold outside air to be pulled in through tiny cracks and gaps to replace the lost volume, forcing your system to work even harder.

The Safety Risk: Backdrafting

The most serious concern with an atmospheric furnace is the potential for backdrafting. If the natural draft in the chimney is weak or overpowered, the flow can reverse. This can happen due to a blocked flue, high winds, or even the use of other exhaust appliances in the home.

When backdrafting occurs, toxic combustion byproducts—most notably carbon monoxide (CO)—spill back into your home instead of safely venting outside, creating a life-threatening hazard.

Susceptibility to Depressurization

Modern, tightly sealed homes are more prone to depressurization. Running a powerful kitchen range hood, a bathroom fan, or a clothes dryer can create enough negative pressure to overpower the furnace's natural draft, increasing the risk of backdrafting.

How to Apply This to Your Home

Your decision to keep, replace, or install an atmospheric furnace should be based on a clear understanding of your priorities.

- If your primary focus is long-term efficiency and lower energy bills: A modern, high-efficiency sealed-combustion furnace is the superior choice, as it doesn't waste heated indoor air.

- If your primary focus is safety and indoor air quality: A sealed-combustion furnace is the definitive solution, as it completely isolates the entire combustion process from your living space.

- If you currently have an atmospheric furnace: It is critical to have it inspected annually by a qualified technician and to have working carbon monoxide detectors on every level of your home.

Understanding the difference between open and sealed combustion empowers you to make the right decision for your home's efficiency and your family's safety.

Summary Table:

| Feature | Atmospheric Furnace | Modern Sealed Furnace |

|---|---|---|

| Combustion Air Source | Indoor air from the room | Outside air via sealed pipe |

| Efficiency | Lower (wastes heated air) | High (up to 98% AFUE) |

| Safety Risk | Potential for backdrafting & CO spillage | Sealed combustion eliminates risk |

| Best For | Older, leakier homes with good ventilation | Modern, tightly sealed homes |

Upgrade Your Heating System with Confidence

While atmospheric furnaces have served many homes, modern sealed-combustion systems offer superior efficiency and eliminate critical safety risks like carbon monoxide backdrafting. At KINTEK, we understand that every home and laboratory has unique thermal processing requirements.

Leveraging our exceptional R&D and in-house manufacturing capabilities, we provide advanced, high-efficiency furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, and specialized Vacuum & Atmosphere Furnaces, all backed by strong deep customization capabilities to precisely meet your needs.

Ready to enhance your safety and efficiency? Contact our experts today for a personalized consultation on the ideal heating solution for your application.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems