A vacuum tube furnace functions as a precision thermal environment specifically engineered to alter the microstructure of Additively Manufactured (AM) Ti6Al4V parts without compromising surface integrity.

It achieves this by maintaining a strict oxygen-free vacuum while heating components to temperatures between 950°C and 1050°C. This thermal cycle decomposes the brittle, metastable martensitic structures typical of AM printing, converting them into stable lamellar alpha+beta phases to relieve residual stress and significantly enhance plasticity.

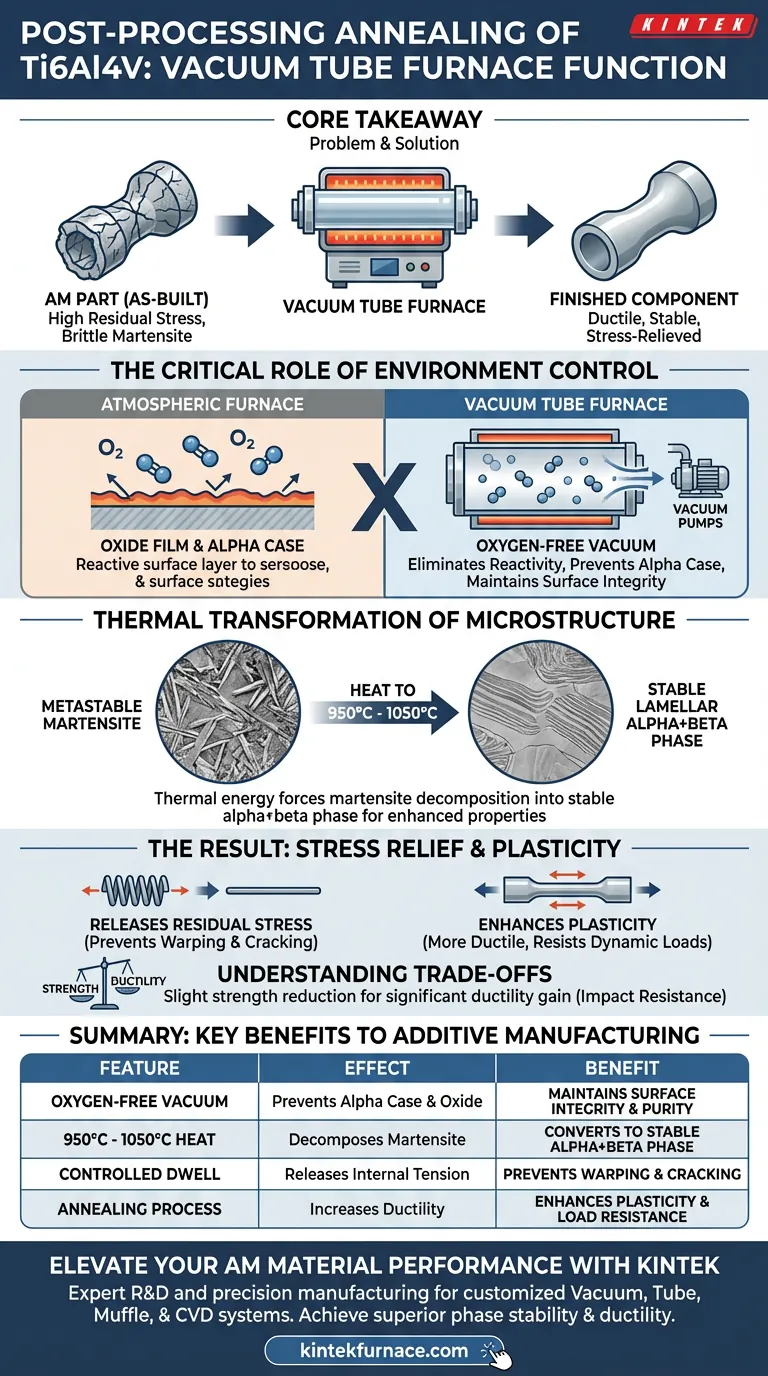

Core Takeaway

Additive manufacturing leaves Ti6Al4V with high residual stresses and a brittle microstructure. The vacuum tube furnace solves this by providing the inert, high-temperature environment required to decompose these unstable phases, transforming the part into a ductile, structurally stable component ready for use.

The Critical Role of Environment Control

Eliminating Reactivity

Titanium alloys, particularly Ti6Al4V, are highly reactive at elevated temperatures. If exposed to oxygen while hot, they rapidly form oxide films that degrade mechanical properties.

The Vacuum Advantage

A vacuum tube furnace creates an oxygen-free atmosphere. This is distinct from standard atmospheric furnaces.

By removing air and impurities, the furnace prevents the formation of a brittle "alpha case" (an oxygen-enriched surface layer). This ensures the surface integrity remains intact during the heating process.

Thermal Transformation of the Microstructure

Addressing the "As-Built" State

Parts produced via additive manufacturing undergo rapid cooling during the printing process.

This rapid cooling freezes the microstructure into a metastable martensitic phase. While hard, this structure is full of residual internal stresses and lacks the ductility required for many structural applications.

The Decomposition Process

The furnace heats the parts to a specific annealing window, typically 950°C or 1050°C.

At these temperatures, the thermal energy forces the metastable martensite to decompose. The material relaxes, and the atoms rearrange themselves into a more natural equilibrium.

Achieving Phase Stability

The end result of this heat treatment is a stable lamellar alpha+beta phase.

This transformation is not merely cosmetic; it fundamentally changes how the material behaves under load. The shift to a lamellar structure provides the internal "slip systems" necessary for the material to stretch rather than snap.

The Result: Stress Relief and Plasticity

Releasing Residual Stress

AM parts often contain significant internal tension from the layer-by-layer melting process.

The high-temperature dwell in the vacuum furnace releases these residual stresses. If left untreated, these stresses could cause the part to warp or crack prematurely during service.

Enhancing Plasticity

The primary output of this specific annealing process is enhanced plasticity.

By converting the brittle martensite into the alpha+beta phase, the material becomes more ductile. This ensures the part can withstand dynamic loads and deformation without catastrophic failure.

Understanding the Trade-offs

While vacuum annealing is essential for Ti6Al4V, it is important to understand the balance of properties.

Strength vs. Ductility

The "as-built" martensitic structure is often extremely strong but brittle. By annealing to specific temperatures like 1050°C to gain plasticity, you may see a slight reduction in ultimate tensile strength compared to the raw printed state. This is a necessary trade-off to ensure the part does not shatter under impact.

Process Sensitivity

The vacuum level must be maintained rigorously. Even a small leak or insufficient vacuum level can lead to surface oxidation, rendering the high-precision part unusable due to surface embrittlement.

Making the Right Choice for Your Goal

To maximize the performance of your Ti6Al4V components, align your heat treatment with your mechanical requirements:

- If your primary focus is Ductility and Reliability: Prioritize annealing at 950°C–1050°C to fully decompose martensite into the stable alpha+beta phase.

- If your primary focus is Geometric Stability: Ensure the vacuum cycle includes a sufficient dwell time to fully relieve residual stresses, preventing warping after the part is removed from the build plate.

Summary: The vacuum tube furnace is not just a heater; it is a phase-transformation tool that converts a printed shape into a structurally sound, ductile engineering component.

Summary Table:

| Feature | Effect on Ti6Al4V Parts | Benefit to Additive Manufacturing |

|---|---|---|

| Oxygen-Free Vacuum | Prevents "alpha case" & oxide films | Maintains surface integrity & purity |

| 950°C - 1050°C Heat | Decomposes brittle martensite | Converts to stable alpha+beta phase |

| Controlled Dwell | Releases internal tension | Prevents warping and cracking |

| Annealing Process | Increases material ductility | Enhances plasticity and load resistance |

Elevate Your AM Material Performance with KINTEK

Don't let residual stress or surface oxidation compromise your titanium components. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you need Vacuum, Tube, Muffle, or CVD systems, our laboratory high-temp furnaces are fully customizable to meet your specific additive manufacturing post-processing requirements.

Ready to achieve superior phase stability and ductility?

Contact our specialists today to find your perfect furnace solution!

Visual Guide

References

- Anna Antolak‐Dudka, Justyna Łukasiewicz. Comparison of the Microstructural, Mechanical and Corrosion Resistance Properties of Ti6Al4V Samples Manufactured by LENS and Subjected to Various Heat Treatments. DOI: 10.3390/ma17051166

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How is the quartz tube furnace constructed for vacuum operations? Discover Key Design Elements for High-Temperature Vacuum Processing

- Why are vacuum-sealed quartz tubes essential for Bi-Sb-Te phase diagrams? Ensure Chemical Fidelity in Your Alloy Synthesis

- What is the function of a dual-zone tube furnace in LPCVD? Master Precise MnSe Nanosheet Synthesis

- What role do industrial tube furnaces play in the oxidation of NiCrAl alloys? Precise Stability for Reliable Data

- How do tube furnaces and isolation valves simulate TCOP experiments? Expert Setup for Thermochemical Oxygen Pumps

- How is a Pulse Ignition device used for coal cloud explosions? Master MAIT Testing with Godbert-Greenwald Furnaces

- How does a high-precision tube furnace facilitate the one-step carbonization of molybdenum carbide catalysts?

- What is the difference between a muffle furnace and a tube furnace? Choose the Right High-Temp Tool