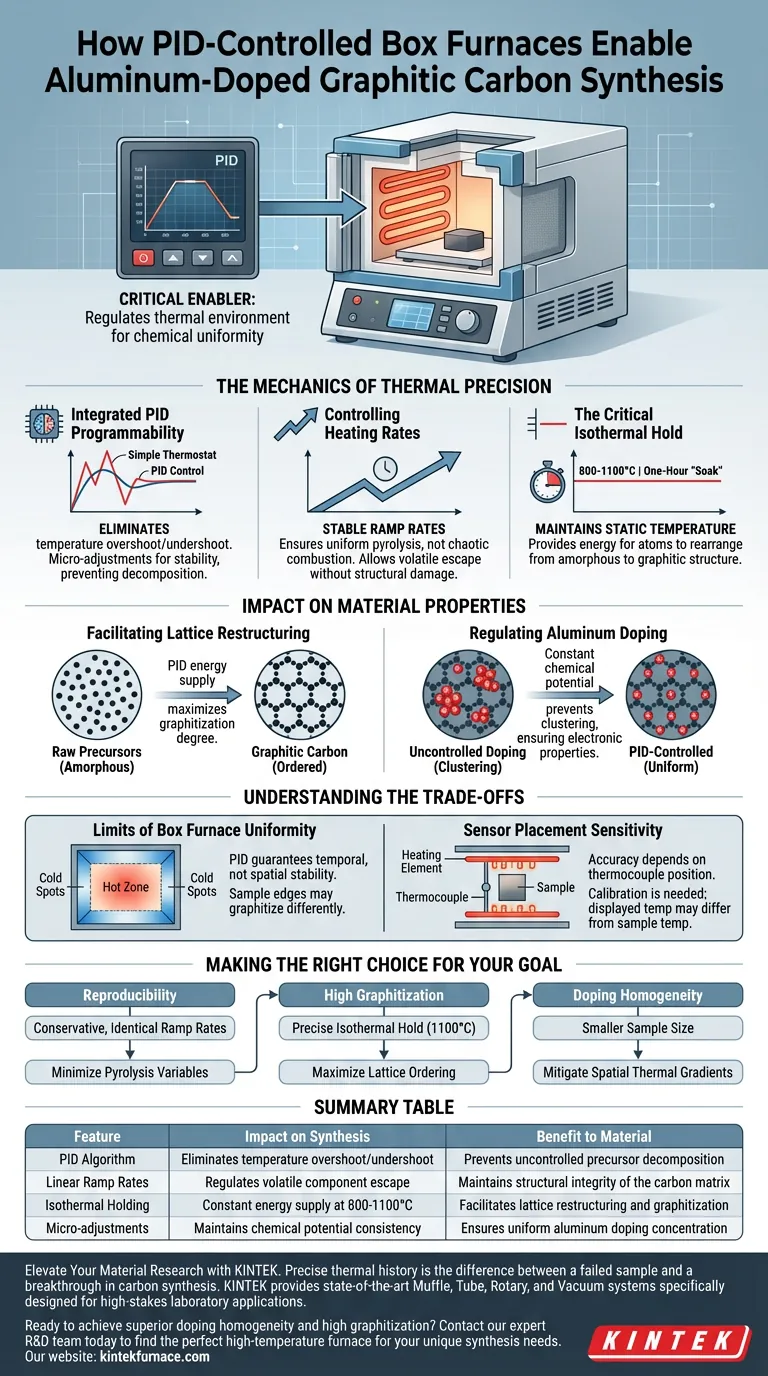

A laboratory box furnace with PID control is the critical enabler for synthesizing aluminum-doped graphitic carbon by strictly regulating the thermal environment required for chemical uniformity. Through a programmable Proportional-Integral-Derivative (PID) controller, the equipment executes precise heating profiles—specifically stable ramp rates and isothermal holds between 800 and 1100°C—which are necessary to drive uniform pyrolysis and correct lattice restructuring.

Synthesis of doped materials is less about achieving a maximum temperature and more about maintaining thermal stability. The PID controller ensures that the specific energy barriers required for aluminum atoms to integrate into the carbon lattice are met consistently, preventing structural defects caused by thermal fluctuations.

The Mechanics of Thermal Precision

Integrated PID Programmability

The core advantage of this furnace type is the integrated PID controller. Unlike simple on/off thermostats, a PID algorithm continuously calculates the error between the desired setpoint and the actual temperature, making micro-adjustments to the power output.

This eliminates temperature "overshoot" or "undershoot." For delicate molecular precursors, this stability prevents rapid, uncontrolled decomposition that would ruin the sample structure.

Controlling Heating Rates

The synthesis process relies on stable heating rates. The furnace must ramp up temperature gradually to allow volatile components to escape without destroying the forming carbon matrix.

PID control ensures this ramp is linear and predictable. This consistency is vital for ensuring that the precursor materials undergo uniform pyrolysis rather than chaotic combustion.

The Critical Isothermal Hold

The primary reference highlights the necessity of a one-hour isothermal hold. This is a period where the temperature remains perfectly static, typically between 800 and 1100°C.

During this "soak" time, the PID controller fights against heat loss to keep the chamber distinctively stable. This duration provides the necessary thermal energy for the carbon atoms to rearrange themselves from an amorphous state into an ordered graphitic structure.

Impact on Material Properties

Facilitating Lattice Restructuring

The transition from raw molecular precursors to graphitic carbon requires lattice restructuring. The high temperatures (up to 1100°C) mobilize the atoms, allowing them to align into hexagonal sheets.

If the temperature fluctuates during this phase, the restructuring is interrupted. The PID-controlled environment ensures the continuous energy supply needed to maximize the degree of graphitization.

Regulating Aluminum Doping

To successfully create aluminum-doped carbon, the dopant atoms must integrate uniformly into the matrix. This is heavily dependent on the uniformity of the thermal environment.

Precise temperature control ensures that the chemical potential remains constant throughout the chamber. This allows for a controlled aluminum doping concentration, preventing the clustering of aluminum atoms which would degrade the material's electronic properties.

Understanding the Trade-offs

The Limits of Box Furnace Uniformity

While PID control offers excellent temporal stability (stability over time), it does not automatically guarantee spatial uniformity (stability across space).

In a standard box furnace, "cold spots" can still exist near the door or corners. If the sample volume is too large, the outer edges may graphitize differently than the center, regardless of how accurate the PID controller is at the sensor point.

Sensor Placement Sensitivity

The accuracy of the synthesis is entirely dependent on the thermocouple placement. The PID controller can only regulate the temperature at the tip of the sensor.

If the sensor is too close to the heating elements and far from the sample, the actual synthesis temperature may differ from the displayed setpoint. This requires careful calibration to ensure the sample actually experiences the target 800-1100°C range.

Making the Right Choice for Your Goal

To maximize the quality of your aluminum-doped graphitic carbon, consider how you program the PID controller based on your specific objectives:

- If your primary focus is Reproducibility: Ensure your ramp rates are conservative and identical across batches to minimize variables in pyrolysis.

- If your primary focus is High Graphitization: Prioritize the precision of the isothermal hold at the upper temperature limit (1100°C) to maximize lattice ordering.

- If your primary focus is Doping Homogeneity: Use a smaller sample size relative to the chamber volume to mitigate spatial thermal gradients that the PID cannot correct.

Success in material synthesis is defined not just by the chemistry, but by the rigor of the thermal history you apply to it.

Summary Table:

| Feature | Impact on Synthesis | Benefit to Material |

|---|---|---|

| PID Algorithm | Eliminates temperature overshoot/undershoot | Prevents uncontrolled precursor decomposition |

| Linear Ramp Rates | Regulates volatile component escape | Maintains structural integrity of the carbon matrix |

| Isothermal Holding | Constant energy supply at 800-1100°C | Facilitates lattice restructuring and graphitization |

| Micro-adjustments | Maintains chemical potential consistency | Ensures uniform aluminum doping concentration |

Elevate Your Material Research with KINTEK

Precise thermal history is the difference between a failed sample and a breakthrough in carbon synthesis. KINTEK provides state-of-the-art Muffle, Tube, Rotary, and Vacuum systems specifically designed for high-stakes laboratory applications. Our furnaces feature advanced PID controllers and are fully customizable to meet the rigorous demands of CVD and lattice restructuring processes.

Ready to achieve superior doping homogeneity and high graphitization?

Contact our expert R&D team today to find the perfect high-temperature furnace for your unique synthesis needs.

Visual Guide

References

- Isabelle P. Gordon, Nicholas P. Stadie. Synthesis and characterization of aluminum-doped graphitic carbon. DOI: 10.1557/s43579-024-00531-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the applications of box type resistance furnaces in material research and development? Unlock Precision in Material Synthesis

- What are the high-temperature applications of a digital muffle furnace? Achieve Precise Thermal Control for Your Lab

- What materials are prohibited from being placed in a high-temperature muffle furnace? Ensure Safety and Protect Your Equipment

- Why is an industrial-grade muffle furnace required for kaolin calcination? Ensure Precise Structural Transformation

- What are the different types of muffle furnaces based on heating elements? Choose the Right One for Your Lab

- What is the primary purpose of a box furnace? Achieve Precise Heat Treatment for Your Materials

- How are muffle furnaces applied in textile manufacturing? Ensure Quality with Precise Ashing Tests

- What role does a laboratory muffle furnace play in cotton waste biochar? Precision Pyrolysis for Carbonization