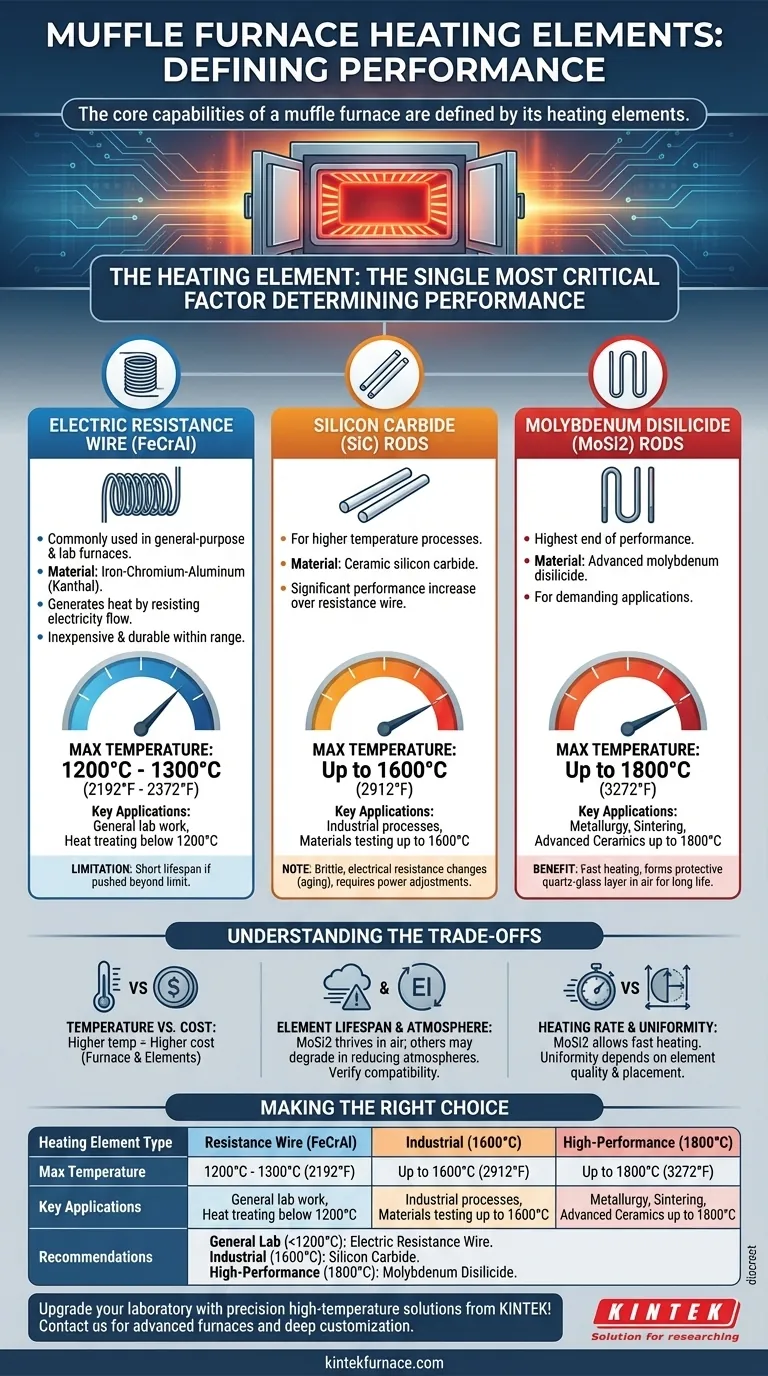

At its core, a muffle furnace's capabilities are defined by its heating elements. The primary types are distinguished by the material used for these elements: electric resistance wire, silicon carbide (SiC) rods, and molybdenum disilicide (MoSi2) rods. Each material dictates the furnace's maximum temperature, heating speed, and suitability for different applications.

The specific heating element inside a muffle furnace is not just a component; it is the single most critical factor determining the furnace's performance envelope. Choosing the right furnace means first understanding the temperature and atmospheric limits imposed by its heating element.

A Closer Look at Heating Element Types

The choice of heating element is a direct trade-off between operating temperature, longevity, and cost. Understanding these three primary categories is the first step in selecting the correct tool for a specific high-temperature process.

Electric Resistance Wire (FeCrAl)

These are the most common heating elements found in general-purpose and laboratory muffle furnaces. They are typically made from an iron-chromium-aluminum alloy, often known by the trade name Kanthal.

These elements work by resisting the flow of electricity, which generates heat. They are relatively inexpensive and durable for applications within their temperature range.

Their primary limitation is a maximum operating temperature of around 1200°C to 1300°C (2192°F to 2372°F). Pushing them beyond this limit drastically shortens their lifespan.

Silicon Carbide (SiC) Rods

For processes requiring higher temperatures, silicon carbide rods are the next step up. These ceramic elements offer a significant performance increase over resistance wire.

SiC rods can operate continuously at temperatures up to 1600°C (2912°F). This makes them suitable for more demanding industrial applications, such as certain glass treatments and materials testing.

They are more brittle than wire elements and their electrical resistance can change over time, a phenomenon known as aging, which may require periodic adjustments to the power supply.

Molybdenum Disilicide (MoSi2) Rods

At the highest end of the performance spectrum are elements made from molybdenum disilicide. These are advanced materials used for the most demanding applications.

MoSi2 elements can achieve working temperatures up to 1800°C (3272°F), enabling sophisticated metallurgical processes like sintering, debinding, and advanced ceramics research.

These elements can be heated very quickly. In an oxidizing atmosphere (like air), they form a protective quartz-glass layer on their surface, which allows for a long service life even at extreme temperatures.

Understanding the Trade-offs

Selecting a furnace is an exercise in balancing performance requirements with practical constraints. The heating element is at the center of this decision.

Temperature vs. Cost

The relationship is direct and unavoidable: the higher the maximum operating temperature, the higher the cost of the furnace and its replacement elements. A MoSi2 furnace represents a significantly larger investment than a standard resistance wire model.

Element Lifespan and Atmosphere

The furnace's internal atmosphere plays a critical role. While MoSi2 elements thrive in air, certain elements may degrade quickly in reducing atmospheres like hydrogen or nitrogen. Always verify that the element material is compatible with your required process gas.

Heating Rate and Uniformity

The material properties directly influence performance. MoSi2 elements allow for exceptionally fast heating rates, improving process efficiency. However, true heating uniformity depends on the quality and placement of the elements within the insulated chamber, regardless of the material type.

Making the Right Choice for Your Application

Your specific process requirements should guide your decision. Consider your maximum required temperature and budget to determine the best fit.

- If your primary focus is general lab work or heat treating below 1200°C: A furnace with electric resistance wire (FeCrAl) elements offers the most cost-effective and reliable solution.

- If your primary focus is industrial processes or materials testing up to 1600°C: A furnace equipped with Silicon Carbide (SiC) elements provides the necessary higher temperature capability.

- If your primary focus is high-performance metallurgy, sintering, or advanced ceramics up to 1800°C: A furnace with Molybdenum Disilicide (MoSi2) elements is essential for achieving these extreme temperatures.

By aligning the heating element's capabilities with your specific temperature and process demands, you ensure both operational success and a sound investment.

Summary Table:

| Heating Element Type | Max Temperature | Key Applications |

|---|---|---|

| Electric Resistance Wire (FeCrAl) | 1200°C - 1300°C | General lab work, heat treating |

| Silicon Carbide (SiC) Rods | Up to 1600°C | Industrial processes, materials testing |

| Molybdenum Disilicide (MoSi2) Rods | Up to 1800°C | Metallurgy, sintering, advanced ceramics |

Upgrade your laboratory with precision high-temperature solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for enhanced efficiency and results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production