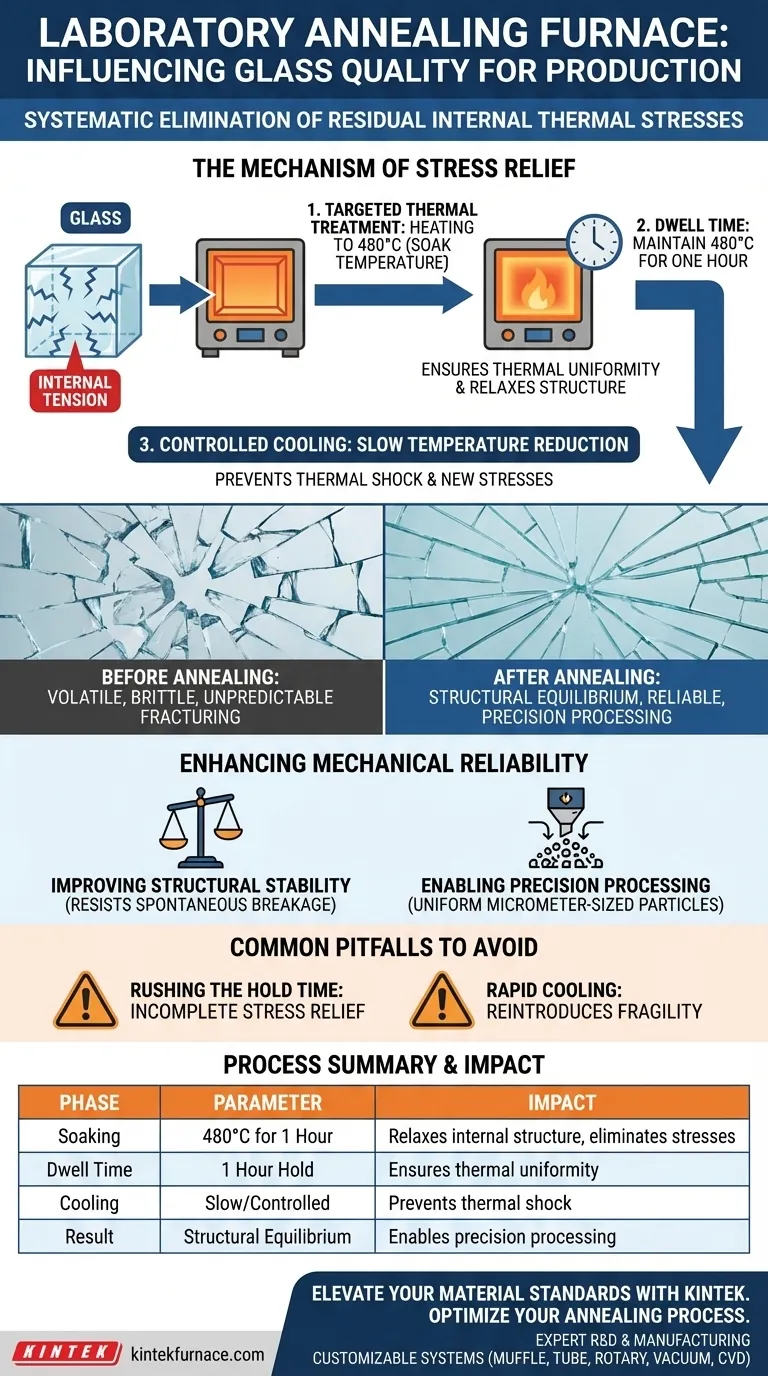

A laboratory annealing furnace fundamentally enhances glass quality by systematically eliminating residual internal thermal stresses. By subjecting the glass to a precise thermal cycle—specifically holding it at 480°C for one hour before slowly cooling it—the furnace ensures the material achieves structural equilibrium. This process is the difference between volatile, brittle glass and a reliable material ready for further processing.

The primary function of the annealing furnace is to stabilize the glass structure by relieving stress concentrations. This ensures the material behaves predictably during mechanical processing, preventing irregular fracturing and ensuring physical uniformity.

The Mechanism of Stress Relief

Targeted Thermal Treatment

Glass naturally develops internal tension during its initial formation. The annealing furnace counteracts this by heating the glass to a specific "soak" temperature, typically 480°C.

The Importance of Dwell Time

Reaching temperature is not enough; the glass must be held there to allow thermal uniformity. Maintaining this temperature for one hour ensures that heat penetrates the entire cross-section of the material, relaxing the internal structure.

Controlled Cooling

The quality of the final product depends heavily on the cooling phase. After the one-hour hold, the furnace slowly lowers the temperature to prevent thermal shock, ensuring that new stresses do not form as the glass hardens.

Enhancing Mechanical Reliability

Improving Structural Stability

Annealed glass possesses superior mechanical reliability compared to untreated glass. By removing the internal forces that pull the material apart, the furnace creates a physically stable product that resists spontaneous breakage.

Enabling Precision Processing

This stability is critical if the glass must be mechanically altered. The annealing process ensures that the glass can be crushed and sieved effectively.

Achieving Uniform Particle Sizes

When untreated glass is crushed, stress concentrations cause it to shatter unpredictably. Annealed glass, however, fractures consistently, allowing for the production of specific micrometer-sized particles without irregular fragmentation.

Common Pitfalls to Avoid

Rushing the Hold Time

A common mistake is reducing the one-hour dwell time at 480°C to increase throughput. This results in incomplete stress relief, leaving the core of the glass under tension while only the surface is relaxed.

Rapid Cooling

Cooling the furnace too quickly negates the benefits of the heat treatment. If the temperature drops too fast after the hold period, thermal gradients will re-emerge, reintroducing the very fragility you attempted to remove.

Making the Right Choice for Your Goal

To maximize the utility of your laboratory annealing furnace, align your process with your specific production needs:

- If your primary focus is Material Stability: strictly adhere to the one-hour hold at 480°C to guarantee the total elimination of internal residual stresses.

- If your primary focus is Particle Production: prioritize the slow cooling phase to ensure the glass fractures predictably during crushing and sieving operations.

By strictly controlling the thermal history of the glass, you ensure a durable product capable of withstanding rigorous downstream processing.

Summary Table:

| Process Phase | Parameter | Impact on Glass Quality |

|---|---|---|

| Soaking | 480°C for 1 Hour | Relaxes internal structure; eliminates residual thermal stresses. |

| Dwell Time | 1 Hour Hold | Ensures thermal uniformity throughout the material cross-section. |

| Cooling | Slow/Controlled | Prevents thermal shock and the reintroduction of new stresses. |

| Result | Structural Equilibrium | Enables precision processing like crushing into micrometer particles. |

Elevate Your Material Standards with KINTEK

Don’t let internal stresses compromise your production quality. KINTEK provides industry-leading laboratory high-temperature furnaces designed for the most demanding annealing and thermal treatment tasks.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific glass production or research needs. Whether you require precise 480°C stabilization or advanced micrometer-sized particle production, our equipment delivers the structural reliability you need.

Contact us today to optimize your annealing process and discover how our expert heating solutions can enhance your laboratory's efficiency.

Visual Guide

References

- I. M. Teixeira, J. W. Menezes. Transforming Rice Husk Ash into Road Safety: A Sustainable Approach to Glass Microsphere Production. DOI: 10.3390/ceramics8030093

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do the structural designs and sealing mechanisms differ between box furnaces and atmosphere furnaces? Choose the Right Furnace for Your Lab

- What function does a precision annealing furnace serve for molten glass? Prevent Cracking and Ensure Sample Stability

- How does a high-temperature furnace facilitate the molten salt synthesis of CoNb2O6? Precision Thermal Control Guide

- What role does a vacuum or atmosphere tube furnace play in the sintering process of Al6061/B4C composites?

- Why is a uniform atmosphere important in carburizing workpieces? Ensure Consistent Hardness and Prevent Failures

- Why is a laboratory chamber with a controlled atmosphere necessary for the laser reduction of graphene oxide (rGO)?

- How does an atmosphere box furnace contribute to the synthesis and preparation of new energy materials? Unlock Precision for Advanced Energy Solutions

- Why is precise temperature control in a tube atmosphere furnace critical? Optimize Your Oxide Precursor Sintering