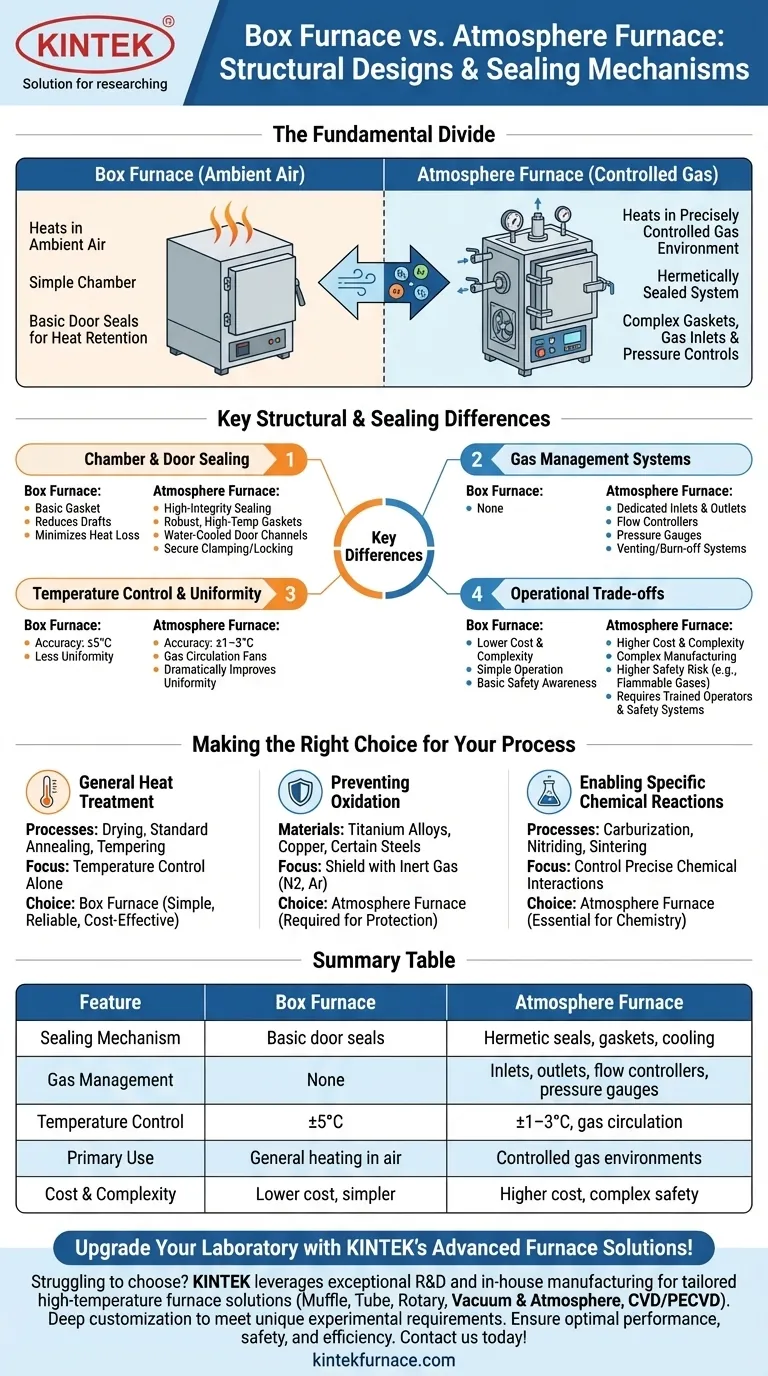

At their core, the structural and sealing differences between a box furnace and an atmosphere furnace are driven by one fundamental factor: a box furnace heats a material in ambient air, while an atmosphere furnace heats it within a precisely controlled gas environment. A box furnace uses a simple chamber with basic door seals designed only to retain heat. In contrast, an atmosphere furnace is a hermetically sealed system with complex gaskets, gas inlets, and pressure controls designed to prevent any interaction with outside air.

The critical distinction is not just how they heat, but what environment they create. A box furnace is for thermal processing alone, whereas an atmosphere furnace is for combined thermal and chemical processing, protecting materials from oxidation or enabling specific chemical reactions.

The Fundamental Divide: Air vs. Controlled Gas

The design of each furnace type is a direct consequence of its intended operating environment. One is built for simplicity and efficiency in air, while the other is engineered for precision and control in a specialized atmosphere.

The Box Furnace: Simplicity for General Heating

A box furnace, often called a muffle furnace, features a simple closed-chamber design. Its primary purpose is to reach and hold a specific temperature in a natural air environment.

The structure is straightforward, typically an insulated box with electric heating elements. Its sealing mechanism is minimal, usually a basic seal on the furnace door designed to minimize heat loss, not to create a gas-tight environment.

The Atmosphere Furnace: Precision for Controlled Reactions

An atmosphere furnace is fundamentally a sealed vessel. Its structure must maintain absolute atmospheric integrity, preventing ambient air from entering and contaminating the process.

This requires a far more complex design. It is equipped with dedicated gas inlet and outlet systems, flow controllers, and pressure gauges. These components allow an operator to introduce specific protective or reactive gases—such as nitrogen, argon, or hydrogen—to achieve a desired outcome.

Key Structural and Sealing Differences

The need to manage an internal atmosphere dictates every aspect of an atmosphere furnace's design, setting it apart from the simpler box furnace.

Chamber and Door Sealing

In a box furnace, the door seal is a basic gasket meant to reduce drafts and improve energy efficiency.

An atmosphere furnace requires high-integrity sealing. This involves robust, high-temperature gaskets, water-cooling channels around the door, and secure clamping or locking mechanisms to ensure the chamber is hermetically sealed. The goal is to prevent both gas leakage and air infiltration.

Gas Management Systems

This is a defining difference. A box furnace has no gas management capabilities.

An atmosphere furnace is built around its gas system. It includes ports for introducing gases, an outlet for venting or burning off excess gas, and systems to monitor and control the flow rate and internal furnace pressure.

Temperature Control and Uniformity

While both control temperature, an atmosphere furnace offers higher precision. Box furnaces typically have an accuracy of ±5°C.

Atmosphere furnaces achieve tighter control, often ±1–3°C. Many also incorporate gas circulation fans to actively distribute the atmosphere, which dramatically improves temperature uniformity throughout the chamber and ensures all parts of the material receive consistent treatment.

Understanding the Operational Trade-offs

The advanced capabilities of an atmosphere furnace come with significant trade-offs in cost, complexity, and safety.

Cost and Manufacturing

The simple design of a box furnace makes it cost-effective to manufacture and maintain.

The complex, leak-proof construction and integrated gas control systems make an atmosphere furnace significantly more expensive. The manufacturing process is more demanding due to the strict sealing requirements.

Safety and Operator Skill

Operating a box furnace is simple and requires only basic high-temperature safety awareness.

Atmosphere furnaces present a higher safety risk. The use of flammable or explosive gases like hydrogen necessitates explosion-proof devices, gas monitoring systems, and professionally trained operators who understand the risks.

Making the Right Choice for Your Process

Your choice depends entirely on whether your material can be exposed to oxygen at high temperatures or if it requires a specific chemical environment.

- If your primary focus is general heat treatment: For processes like drying, standard annealing, or tempering where exposure to air is acceptable, a box furnace is the simple, reliable, and cost-effective solution.

- If your primary focus is preventing oxidation: For processing oxidation-sensitive materials like titanium alloys, copper, or certain steel grades, an atmosphere furnace is required to shield the material with an inert gas like nitrogen or argon.

- If your primary focus is enabling specific chemical reactions: For advanced processes like carburization, nitriding, or sintering metal powders in a reducing environment, an atmosphere furnace is essential to control the precise chemical interactions.

Ultimately, your decision comes down to controlling temperature alone versus controlling both temperature and chemistry.

Summary Table:

| Feature | Box Furnace | Atmosphere Furnace |

|---|---|---|

| Sealing Mechanism | Basic door seals for heat retention | Hermetic seals with gaskets, water-cooling, and clamping |

| Gas Management | None | Gas inlets, outlets, flow controllers, and pressure gauges |

| Temperature Control | ±5°C accuracy | ±1–3°C accuracy with gas circulation for uniformity |

| Primary Use | General heating in air (e.g., drying, annealing) | Controlled gas environments (e.g., oxidation prevention, chemical reactions) |

| Cost and Complexity | Lower cost, simpler design | Higher cost, complex manufacturing and safety features |

Upgrade Your Laboratory with KINTEK's Advanced Furnace Solutions!

Struggling to choose between a box furnace and an atmosphere furnace for your specific needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Whether you need simple heat treatment or complex controlled environments, we ensure optimal performance, safety, and efficiency. Don't let equipment limitations hold back your research—contact us today to discuss how our furnaces can enhance your processes and deliver reliable results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality