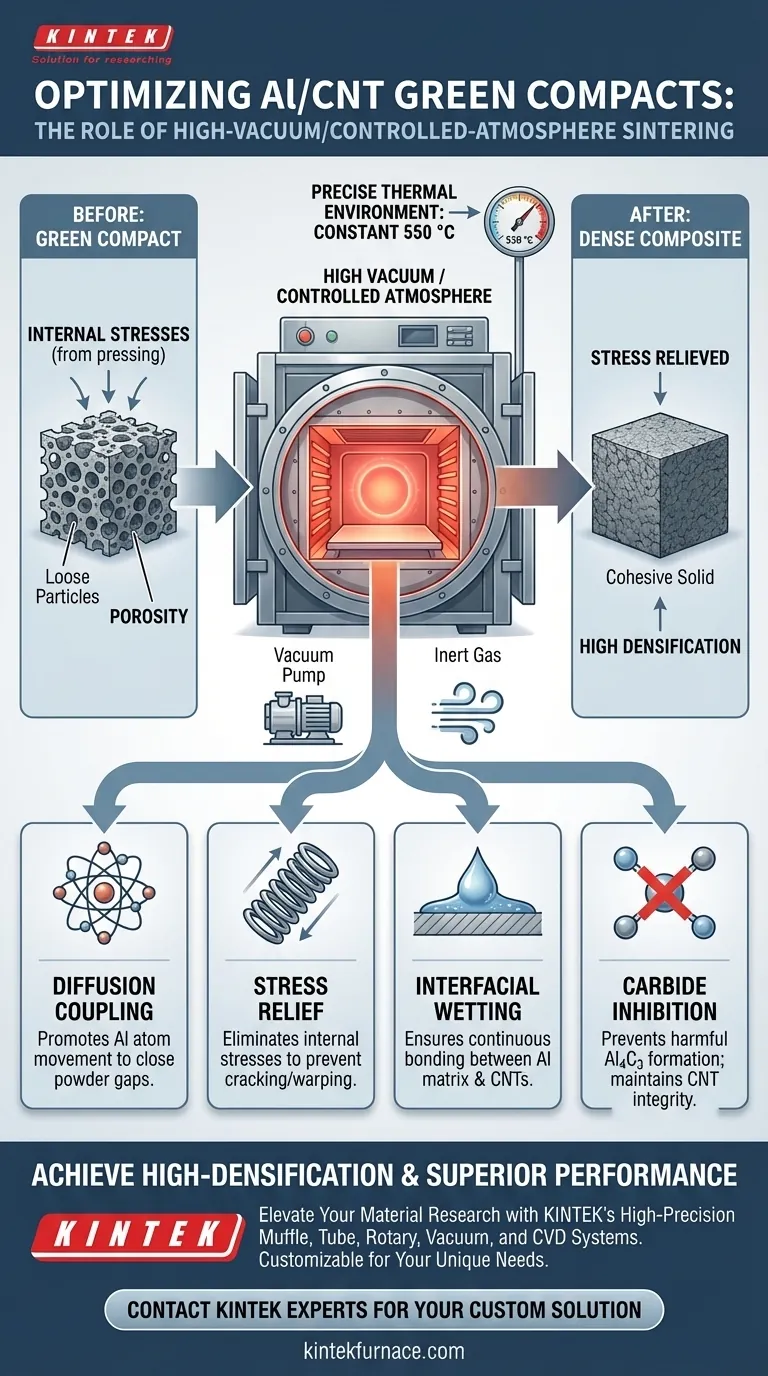

A high-vacuum or controlled-atmosphere sintering furnace optimizes the microstructure of Al/CNT green compacts by maintaining a precise thermal environment, specifically at a constant temperature of 550 °C. This controlled heating promotes the diffusion coupling of aluminum atoms, eliminates internal stresses caused by the initial pressing, and significantly improves interfacial wetting between the matrix and the nanotubes. By strictly regulating the temperature and atmosphere, the furnace ensures high densification while preventing the formation of harmful aluminum carbides (Al4C3).

The Core Takeaway: The furnace transforms the green compact into a dense composite by balancing atomic diffusion and stress relief. Its primary function is to facilitate strong mechanical bonding between aluminum and carbon nanotubes while suppressing chemical reactions that lead to brittle carbide phases.

The Mechanics of Structural Enhancement

Promoting Diffusion Coupling

The primary mechanism for microstructural change occurs at 550 °C. At this specific temperature, the furnace environment encourages the diffusion coupling of aluminum atoms.

This atomic movement is essential for closing the gaps between powder particles found in the green compact. It transitions the material from a loose collection of pressed particles into a cohesive solid.

Eliminating Internal Stresses

Green compacts enter the furnace carrying significant internal stress generated during the initial pressing or molding phase.

The controlled thermal profile allows the material to relax. This eliminates these residual stresses, reducing the risk of cracking or warping in the final component.

Improving Interfacial Wetting

For a composite to be strong, the metal matrix must "wet" the reinforcement material effectively.

The furnace conditions improve the interfacial wetting between the aluminum and the carbon nanotubes. This ensures that the aluminum flows closely around the nanotubes, creating a continuous interface rather than leaving microscopic voids.

Chemical Control and Densification

Preventing Harmful Carbide Formation

One of the most critical roles of the controlled atmosphere is chemical inhibition.

High temperatures can cause carbon nanotubes to react with aluminum, forming aluminum carbide (Al4C3). The reference identifies this as a "harmful" phase, likely because it degrades the mechanical properties of the nanotubes.

By maintaining a precise 550 °C profile, the furnace facilitates bonding without triggering this detrimental chemical reaction.

Achieving High Densification

The combination of diffusion, wetting, and stress relief leads to high densification.

The furnace removes porosity inherent in the green compact. The result is a solid material with a strong mechanical bond between the aluminum matrix and the carbon nanotubes.

Understanding the Trade-offs

The Necessity of Precision

The effectiveness of this process relies entirely on the precision of the thermal environment.

The reference explicitly emphasizes a constant 550 °C. Deviating from this specific temperature could either fail to induce necessary diffusion (too cool) or trigger carbide formation (too hot).

Controlled Atmosphere Requirements

You cannot achieve these results in an open-air environment.

A high vacuum or controlled atmosphere is non-negotiable to prevent oxidation of the aluminum. Without this control, oxides would form at the grain boundaries, inhibiting diffusion and weakening the final composite.

Making the Right Choice for Your Goal

To maximize the performance of Al/CNT composites, you must align your processing parameters with your specific material objectives.

- If your primary focus is mechanical strength: Ensure the temperature profile remains strictly at 550 °C to maximize interfacial wetting and prevent brittle Al4C3 formation.

- If your primary focus is dimensional stability: Prioritize the "hold" time at temperature to fully eliminate internal stresses generated during the pressing of the green compact.

Success in sintering Al/CNT composites depends on leveraging the furnace to balance physical densification with chemical inertness.

Summary Table:

| Key Mechanism | Function & Impact | Critical Parameter |

|---|---|---|

| Diffusion Coupling | Promotes aluminum atom movement to close powder gaps. | Constant 550 °C |

| Stress Relief | Eliminates internal stresses from initial pressing to prevent cracking. | Precise Thermal Profile |

| Interfacial Wetting | Ensures continuous bonding between Al matrix and nanotubes. | Controlled Atmosphere |

| Carbide Inhibition | Prevents formation of brittle Al4C3 to maintain CNT integrity. | Thermal Precision |

| Densification | Removes porosity to create a cohesive, high-strength solid. | Vacuum/Inert Gas |

Elevate Your Material Research with KINTEK

Optimize your Al/CNT composite production with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique research and production needs.

Whether you are aiming for perfect interfacial wetting or need to prevent harmful carbide formation, our advanced high-temp furnaces provide the stability and control required for superior material performance.

Ready to achieve high-densification results? Contact our experts today to find your custom furnace solution!

Visual Guide

References

- Hamed Rezvanpour, Alberto Vergnano. A Flake Powder Metallurgy Approach for Fabricating Al/CNT Composites: Combining Dual-Matrix and Shift-Speed Ball Milling to Optimize Mechanical Properties. DOI: 10.3390/designs9040082

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of high-temperature sintering furnaces in the densification of Ga2O3:Er targets?

- Which performance characteristics of ultra-high temperature graphite furnaces are essential for Boron Carbide sintering?

- Why is a vacuum annealing furnace required for WSe2 Schottky detectors? Optimize Interfaces for Peak Performance

- How are vacuum sintering furnaces categorized based on temperature ranges? Find the Right Furnace for Your Materials

- What is the technical necessity of the vacuum oven drying step for Bi@C electrode sheets? Ensure Purity and Adhesion

- What key process conditions do high-temperature vacuum furnaces provide for the thermal hydrogen treatment of Ti–6Al–4V?

- How does the evacuation process work in a vacuum furnace? Achieve Precise Metallurgical Control

- Why is a laboratory vacuum oven necessary for drying degraded LTGP samples? Ensure Pure Surface Analysis Results