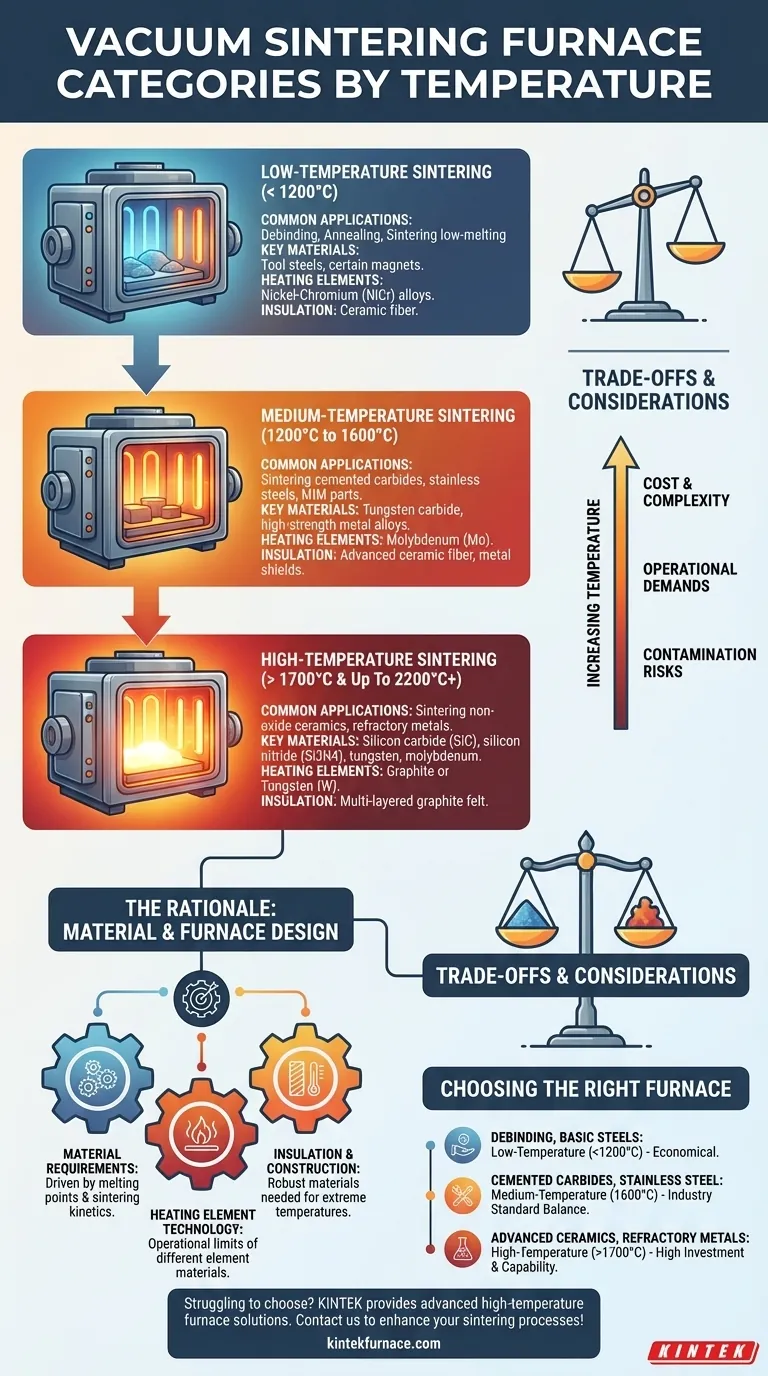

In practice, vacuum sintering furnaces are broadly categorized into three temperature ranges, though the exact boundaries can vary. The most common classification groups them as low-temperature (below 1200°C), medium-temperature (1200°C to 1600°C), and high-temperature (above 1700°C). This classification is a practical guideline driven by the capabilities of the furnace's internal components and the materials they are designed to process.

The temperature classification of a vacuum sintering furnace is not an arbitrary label; it is a direct reflection of the materials it can process. The choice of furnace—and its associated cost and complexity—is fundamentally dictated by the melting points and sintering kinetics of the target material.

The Rationale Behind Temperature Ranges

Understanding why these categories exist is more important than memorizing the exact numbers. The classification is a direct result of material science and engineering limitations.

Material Requirements Drive Furnace Design

The primary factor is the sintering temperature of the material itself. Different materials require vastly different thermal energy levels to cause jejich particles to bond and densify.

For example, certain tool steels sinter effectively below 1200°C, while advanced ceramics like silicon nitride require temperatures well over 1700°C to achieve full density.

Heating Element Technology

The furnace's maximum temperature is determined by its heating elements. Different materials are used for these elements, each with a distinct operational temperature limit.

- Nickel-Chromium (NiCr) alloys are common in the lowest-temperature furnaces.

- Molybdenum (Mo) is the workhorse for medium-temperature ranges, often up to 1600°C or slightly higher.

- Graphite or Tungsten (W) are required for high and ultra-high temperatures, as they can operate reliably above 1700°C and even past 2200°C.

Insulation and Construction

As temperatures increase, so do the demands on the furnace's insulation and structural integrity.

Low-temperature furnaces may use ceramic fiber insulation, while high-temperature models require more robust (and expensive) materials like multi-layered graphite felt to prevent heat loss and maintain structural stability.

A Breakdown of the Temperature Categories

Each category serves a distinct set of industrial and research applications, defined by the materials it can successfully sinter.

Low-Temperature Sintering (Up to ~1200°C)

This range is often used for the initial stages of processing, like debinding, where a binder material is burned out of a green part before final sintering.

It is also sufficient for sintering some low-melting point alloys and certain types of magnets and tool steels. These furnaces are the most common and cost-effective.

Medium-Temperature Sintering (~1200°C to 1600°C)

This is the most versatile and widely used category. It is the industry standard for processing cemented carbides (like tungsten carbide with a cobalt binder), stainless steels, and various high-strength metal alloys.

Furnaces in this range, often specified as 1400°C or 1600°C models, offer a strong balance of material capability and operational cost.

High-Temperature Sintering (>1700°C)

This category is reserved for advanced and specialty materials. It is essential for sintering non-oxide ceramics like silicon carbide (SiC) and silicon nitride (Si3N4), as well as refractory metals like tungsten and molybdenum.

These furnaces, which can reach 2200°C or higher, represent a significant investment and are used in high-tech fields like aerospace, defense, and advanced electronics.

Understanding the Trade-offs

Choosing a furnace is not simply about picking the highest temperature. Higher capability comes with significant compromises.

Cost vs. Capability

The cost of a vacuum furnace increases exponentially with its maximum operating temperature. A high-temperature furnace is not just more expensive to purchase but also to operate, due to higher energy consumption and more costly replacement parts (heating elements, insulation).

Operational Complexity

High-temperature furnaces require more sophisticated control systems and stricter operational protocols. Heating and cooling cycles are often longer, and the risk of damaging a very expensive furnace through operator error is much greater.

Material Contamination Risks

At extreme temperatures, even the furnace's internal components can become a source of contamination. For instance, a graphite heating element can introduce carbon into a sensitive material, which may be undesirable for certain high-purity ceramic or metal applications.

Making the Right Choice for Your Application

Your material dictates your needs. Use the application to guide your selection and avoid paying for unnecessary capability.

- If your primary focus is debinding, annealing, or sintering basic tool steels: A low-temperature furnace (up to 1200°C) is the most economical and efficient choice.

- If your primary focus is cemented carbides, stainless steel, or MIM parts: A medium-temperature furnace (up to 1600°C) is the industry standard, offering the best balance of performance and cost.

- If your primary focus is advanced ceramics or refractory metals: You must invest in a high-temperature furnace (1700°C+) and be prepared for its higher initial and ongoing operational costs.

Ultimately, matching the furnace's temperature range to your specific material requirements is the most critical decision for achieving successful and repeatable sintering.

Summary Table:

| Temperature Range | Common Applications | Key Materials |

|---|---|---|

| Low (< 1200°C) | Debinding, annealing | Tool steels, low-melting alloys |

| Medium (1200-1600°C) | Sintering cemented carbides, stainless steel | Tungsten carbide, metal alloys |

| High (> 1700°C) | Advanced ceramics, refractory metals | Silicon carbide, tungsten |

Struggling to choose the right vacuum sintering furnace for your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you're working with tool steels, cemented carbides, or advanced ceramics. Don't let temperature limitations hold back your research—contact us today to discuss how our tailored solutions can enhance your sintering processes and drive innovation in your laboratory!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What critical process environments does a vacuum annealing furnace provide? Optimize Sm2Fe17Cx Alloy Heat Treatment

- What is a vacuum sintering furnace and what is its primary purpose? Achieve High-Purity, Dense Materials with Precision

- What environmental benefits does a vacuum furnace provide? Boost Sustainability with Clean, Efficient Heat Treatment

- What is the purpose of a high vacuum welding furnace in cemented carbide and tool manufacturing? Ensure Strong, Contamination-Free Bonds

- How does vacuum degree affect the sintering atmosphere? Optimize Material Purity and Performance

- What are the core tasks of vacuum and temperature systems in CSS for CZT films? Essential Control for High Performance

- Which metals are commonly joined using a brazing oven? Unlock Versatile Metal Joining Solutions

- What is vacuum sintering and where is it commonly used? Discover High-Purity Material Processing