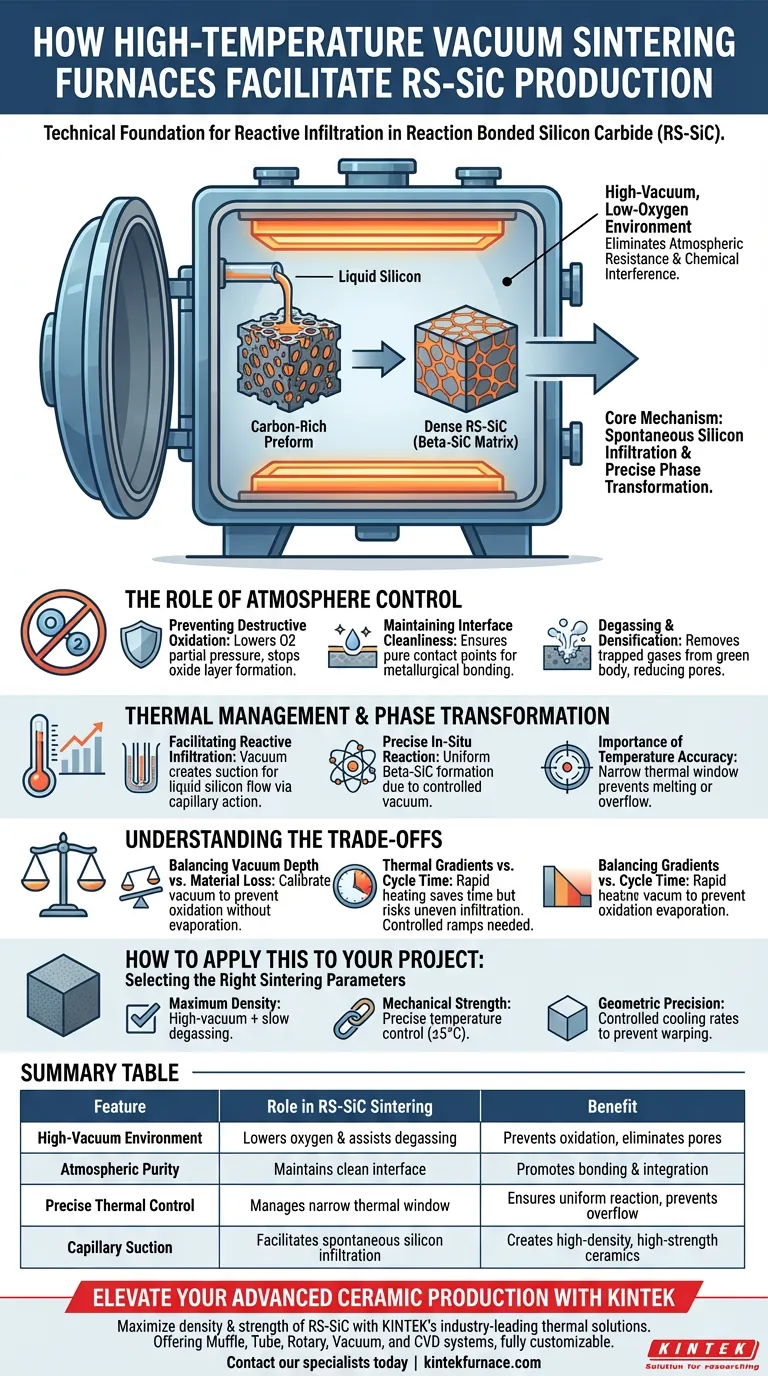

High-temperature vacuum sintering furnaces are the technical foundation for RS-SiC production, providing the thermal precision and atmospheric purity required to facilitate "reactive infiltration." By creating a high-vacuum, low-oxygen environment, the furnace allows liquid silicon to penetrate a carbon-rich preform and react in-situ to form a dense, high-strength ceramic without the interference of oxidation or gas entrapment.

The core mechanism of a vacuum sintering furnace in RS-SiC production is the elimination of atmospheric resistance and chemical interference. This allows for spontaneous silicon infiltration and precise phase transformation, resulting in a material with superior density and bonding strength.

The Role of Atmosphere Control

Preventing Destructive Oxidation

At the high temperatures required for sintering, silicon and carbon are highly reactive with oxygen. The vacuum environment lowers oxygen partial pressure, preventing the formation of oxide layers that would otherwise block the reaction or weaken the final structure.

Maintaining Interface Cleanliness

A high vacuum ensures that the contact points between the silicon carbide particles and the carbon matrix remain chemically "clean." This purity is essential for promoting metallurgical bonding and ensuring that the newly formed beta-SiC integrates seamlessly into the existing matrix.

Degassing and Densification

The vacuum environment actively assists in the discharge of internal gases from the "green body" or preform. By removing these trapped gases, the furnace reduces internal pores and defects, leading to a significantly denser and more consistent final product.

Thermal Management and Phase Transformation

Facilitating Reactive Infiltration

Once the furnace raises the temperature above the melting point of silicon, the vacuum creates a suction effect. This environment allows the liquid silicon to spontaneously flow into the pores of the carbon preform through capillary action.

Precise In-Situ Reaction

Within the furnace, the infiltrated liquid silicon reacts directly with the carbon in the preform to create new beta-SiC. Because this happens in a controlled vacuum, the reaction is uniform, and the resulting bonding between phases is exceptionally strong.

Importance of Temperature Accuracy

Precise temperature control is mandatory because RS-SiC sintering requires a narrow thermal window. Even minor deviations can cause material melting or overflow, which would lead to a sharp decline in material density and mechanical integrity.

Understanding the Trade-offs

Balancing Vacuum Depth and Material Loss

While a high vacuum is necessary for purity, excessive vacuum levels at very high temperatures can sometimes lead to the evaporation of certain elements. Engineers must carefully calibrate the vacuum level to ensure it is deep enough to prevent oxidation but stable enough to prevent unintended material loss.

Thermal Gradients vs. Cycle Time

Rapid heating can reduce cycle times but may introduce thermal gradients within the part, leading to uneven silicon infiltration. Achieving a perfectly uniform reaction requires slower, controlled heating ramps, which increases the overall energy consumption and production time of the process.

How to Apply This to Your Project

Selecting the Right Sintering Parameters

The success of RS-SiC production depends on aligning your furnace capabilities with your specific material requirements.

- If your primary focus is Maximum Density: Prioritize a furnace with high-vacuum capabilities and a slow degassing phase to ensure all internal pores are evacuated before silicon infiltration begins.

- If your primary focus is Mechanical Strength: Focus on precise temperature control systems (within ±5°C) to ensure the in-situ reaction forms a uniform beta-SiC phase without overheating the matrix.

- If your primary focus is Geometric Precision: Utilize a vacuum furnace that allows for controlled cooling rates to minimize internal stresses and prevent cracking or warping after the reaction is complete.

By leveraging the vacuum environment to control chemical reactions at the molecular level, you can transform a porous preform into a high-performance, industrial-grade ceramic.

Summary Table:

| Feature | Role in RS-SiC Sintering | Benefit |

|---|---|---|

| High-Vacuum Environment | Lowers oxygen partial pressure & assists degassing | Prevents oxidation and eliminates internal pores/defects |

| Atmospheric Purity | Maintains clean interface between Si and Carbon matrix | Promotes superior metallurgical bonding and phase integration |

| Precise Thermal Control | Manages narrow thermal window for silicon melting | Ensures uniform in-situ reaction and prevents material overflow |

| Capillary Suction | Facilitates spontaneous liquid silicon infiltration | Creates high-density, high-strength ceramics from porous preforms |

Elevate Your Advanced Ceramic Production with KINTEK

Maximize the density and mechanical strength of your Reaction Bonded Silicon Carbide (RS-SiC) with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered for high-performance laboratory and industrial applications.

Whether you require high-vacuum capabilities for gas-free densification or ultra-precise temperature uniformity for phase stability, our systems are fully customizable to your unique material needs. Don't settle for less than perfect structural integrity. Contact our specialists today to discover how our high-temperature furnace technology can optimize your sintering process!

Visual Guide

References

- Bety Al-Saqarat, Ehab AlShamaileh. Study of Galena Ore Powder Sintering and Its Microstructure. DOI: 10.3390/met14040439

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What types of metals and alloys are suitable for vacuum heat treatment furnaces? Essential Guide for High-Performance Materials

- What role do high-temperature vacuum furnaces play in CVD and PVD processes? Essential for Purity and Precision in Thin-Film Deposition

- What is the maximum operating temperature for molybdenum in vacuum furnaces? Key to High-Temp Processing

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a laboratory vacuum annealing furnace play in ion-implanted ScN thin films? Restore Lattice Integrity

- What material limitations do vacuum furnaces have? Avoid Contamination and Ensure Process Purity

- How can vacuum furnace chillers reduce operating costs? Boost Efficiency and Cut Hidden Expenses

- How do heat treatment and vacuum furnaces contribute to industrial innovation? Unlock Superior Material Performance