The primary material limitation of a vacuum furnace is its unsuitability for processing materials with a high vapor pressure. Elements such as zinc, lead, manganese, copper, and chromium can turn into a gas at high temperatures under vacuum, a process known as outgassing. This evaporation can alter the workpiece's surface composition and contaminate the furnace interior, compromising both the part and the equipment.

The core challenge of vacuum furnace operation extends beyond material selection. It requires balancing the absolute need for a contamination-free environment against the significant risks of material evaporation and the high operational costs inherent in creating a vacuum.

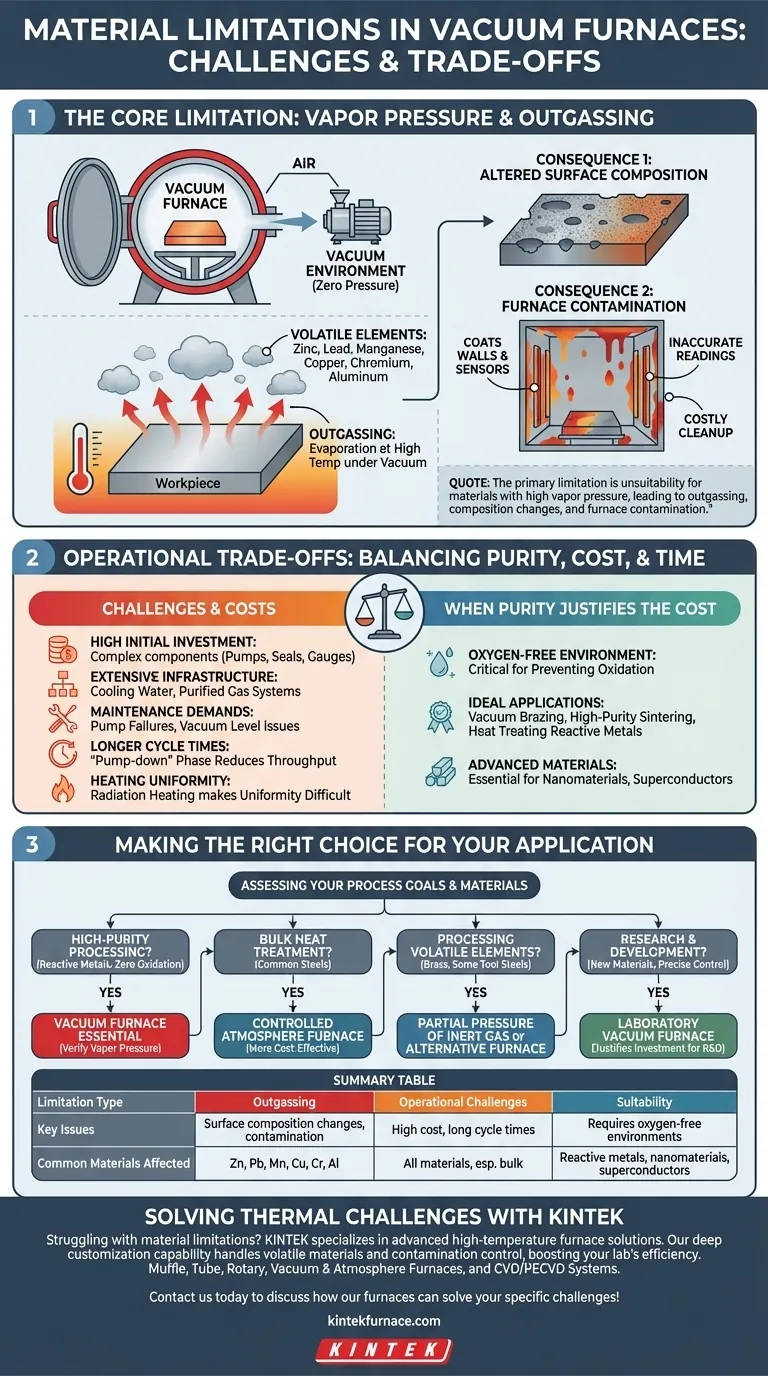

The Core Limitation: Vapor Pressure and Outgassing

A vacuum furnace's unique environment is both its greatest strength and the source of its primary limitation. By removing atmospheric gases, it enables incredibly pure thermal processing, but it also fundamentally changes how materials behave at high temperatures.

Why High Vapor Pressure Is a Problem

In a vacuum, the pressure pushing down on a material is virtually zero. This dramatically lowers the temperature at which elements can "boil" or evaporate.

Materials with a high saturated vapor pressure are prone to this effect. As the furnace heats up, these volatile elements transform into a gas, leaving the surface of the workpiece. This includes common alloying elements like zinc, lead, and manganese, and even base metals like aluminum and copper under certain conditions.

The Consequences of Outgassing

Outgassing is not a minor issue; it has cascading negative effects on the process and the equipment.

First, it alters the material's composition. The loss of key alloying elements from the surface can prevent the workpiece from achieving its desired metallurgical properties.

Second, the evaporated metal vapor contaminates the furnace interior. It coats the cool walls, the heating elements, and critical sensors like thermocouples. This can lead to inaccurate temperature readings, electrical shorts, and costly, time-consuming cleanup.

Understanding the Operational Trade-offs

Beyond material compatibility, vacuum furnaces present distinct operational and financial considerations that differ significantly from atmospheric furnaces. The decision to use one must account for these realities.

High Initial Investment and Maintenance

Vacuum furnaces are complex machines. Their high cost stems from the need for precision components like vacuum pumps, gauges, and high-integrity seals.

They also require extensive supporting infrastructure, including cooling water systems and purified gas systems. This complexity leads to higher maintenance demands and the potential for issues like pump failures or vacuum level inconsistencies.

Process Challenges: Heating and Cycle Time

Heating in a vacuum occurs primarily through radiation, as there is no air to transfer heat via convection. This can make it difficult to achieve uniform heating across large or geometrically complex parts without specialized tooling and careful process design.

Furthermore, every cycle requires a "pump-down" phase to remove the air and achieve the target vacuum level. This adds significant time compared to atmospheric furnaces, reducing overall throughput.

When the Purity Justifies the Cost

Despite these challenges, the benefits are undeniable for specific applications. A vacuum furnace provides a perfectly oxygen-free environment, which is critical for preventing oxidation on sensitive materials.

This makes it the ideal choice for processes like vacuum brazing, high-purity sintering, and heat treating reactive metals. For advanced materials like nanomaterials or superconductors, the pristine environment is not just a benefit—it is a requirement for their formation.

Making the Right Choice for Your Application

Choosing the right thermal processing technology requires a clear-eyed assessment of your material, your process goals, and your budget.

- If your primary focus is high-purity processing: A vacuum furnace is essential for reactive metals or parts where any surface oxidation is unacceptable, but you must first verify your material's vapor pressure characteristics.

- If your primary focus is bulk heat treatment of common steels: The cost, complexity, and cycle times of a vacuum furnace may be unnecessary; a controlled atmosphere furnace is often a more practical and cost-effective choice.

- If you are processing materials with volatile elements (e.g., brass, some tool steels): You must either use a furnace capable of introducing a partial pressure of inert gas to suppress evaporation or select an alternative furnace technology entirely.

- If your primary focus is research and development: A laboratory vacuum furnace provides the precise, repeatable control necessary for creating new materials, justifying the investment for small-scale, high-value work.

Ultimately, selecting a vacuum furnace requires a careful evaluation of your material's properties against your process's strict demand for purity and control.

Summary Table:

| Limitation Type | Key Issues | Common Materials Affected |

|---|---|---|

| Material Compatibility | Outgassing, surface composition changes, furnace contamination | Zinc, lead, manganese, copper, chromium, aluminum |

| Operational Challenges | High cost, long cycle times, heating uniformity issues | All materials, especially in bulk processing |

| Suitability | Requires oxygen-free environments for purity | Reactive metals, nanomaterials, superconductors |

Struggling with material limitations in your thermal processes? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise handling of volatile materials and contamination control, enhancing your lab's efficiency and results. Contact us today to discuss how our furnaces can solve your specific challenges and boost your productivity!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing