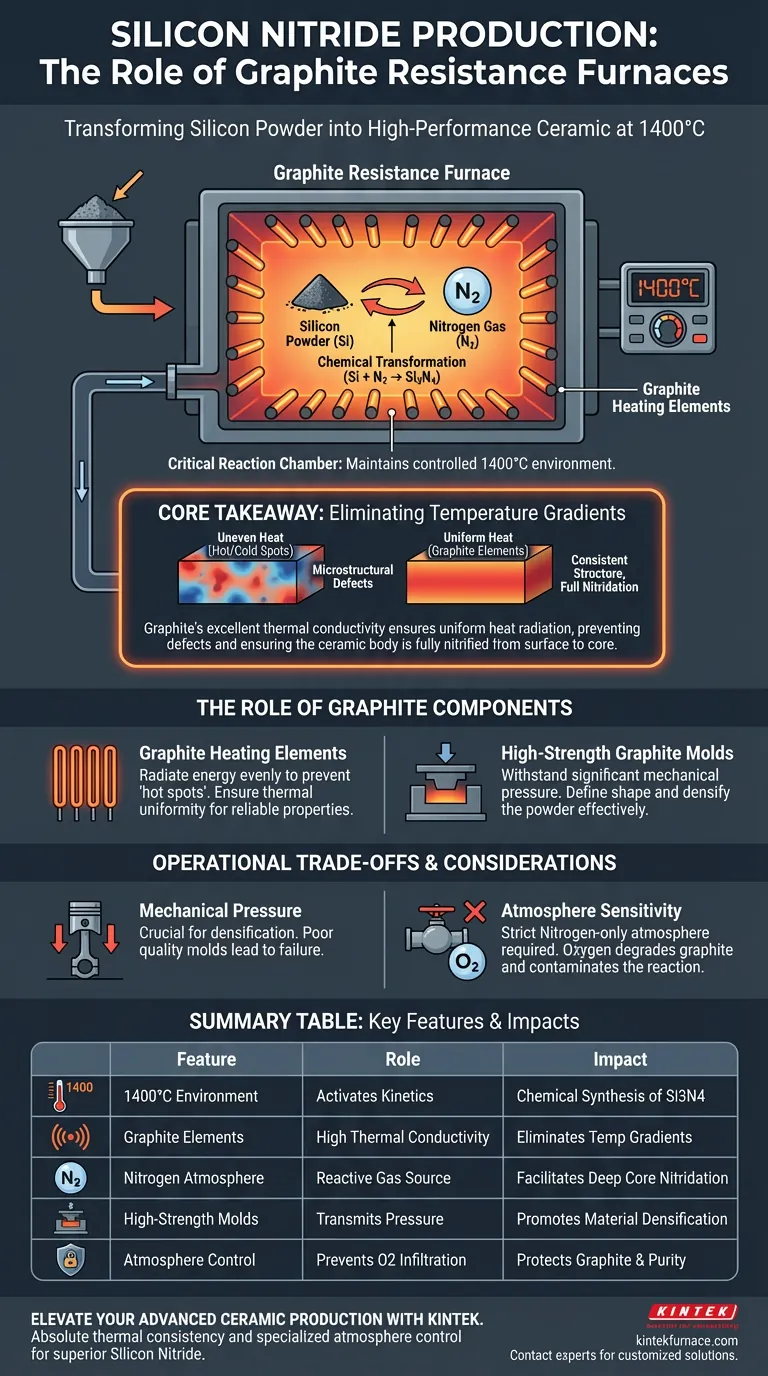

A graphite resistance furnace acts as the critical reaction chamber where solid silicon powder is transformed into high-performance ceramic. It facilitates this process by maintaining a strictly controlled environment at approximately 1400°C, enabling the chemical reaction between silicon and nitrogen gas to produce Silicon Nitride (Si3N4).

Core Takeaway The success of the nitridation process relies on the furnace's ability to eliminate temperature gradients. By utilizing graphite heating elements, the furnace ensures highly uniform heat distribution, guaranteeing that the ceramic body is fully nitrified from the surface down to the internal core.

The Mechanism of Nitridation

Establishing the Reaction Environment

To convert silicon powder into ceramic, the furnace must achieve and sustain high temperatures, typically centered around 1400°C.

This specific thermal threshold is required to activate the chemical potential of the materials involved. Without stable high heat, the reaction kinetics would be insufficient for industrial production.

The Chemical Transformation

Inside the heated chamber, a gas-solid reaction occurs. Solid silicon powder is exposed to a flow of nitrogen gas.

Under the influence of the furnace's heat, these elements combine chemically to synthesize Silicon Nitride (Si3N4), fundamentally changing the material's properties from a metal powder to a distinct ceramic compound.

The Role of Graphite Components

Ensuring Thermal Uniformity

The primary advantage of this furnace type lies in the graphite heating elements.

Graphite possesses excellent thermal conductivity, which allows the heating elements to radiate energy evenly. This prevents "hot spots" or cold zones within the furnace chamber that could lead to uneven processing.

Preventing Microstructural Defects

Temperature gradients are the enemy of ceramic quality. If one part of the sample heats faster than another, it causes microstructural inhomogeneity.

The thermal properties of the graphite components mitigate this risk, ensuring the sample heats uniformly. This results in a consistent internal structure and reliable mechanical properties.

Achieving Deep Core Nitridation

For the final product to be viable, the reaction cannot be superficial.

The uniform distribution provided by the graphite elements ensures the ceramic green body achieves complete nitridation. This means the chemical conversion penetrates effectively from the outer surface all the way to the internal core.

Understanding the Operational Trade-offs

Mechanical Pressure Requirements

While the furnace provides heat, the process often involves defining the geometric shape of the billet using graphite molds.

These molds must withstand significant mechanical pressure to transmit force effectively to the powder. If the graphite quality is poor or the design is weak, it will fail to densify the powder correctly, regardless of the temperature stability.

Atmosphere Sensitivity

Graphite is highly effective at 1400°C, but it is also sensitive to oxidation.

While the process requires Nitrogen gas for the reaction, the furnace environment must be strictly controlled to prevent the introduction of oxygen, which would degrade the graphite components and contaminate the silicon reaction.

Making the Right Choice for Your Goal

When evaluating graphite resistance furnaces for silicon nitridation, consider your specific production priorities:

- If your primary focus is Structural Homogeneity: Prioritize furnace designs with advanced graphite element configurations to maximize thermal conductivity and eliminate temperature gradients.

- If your primary focus is Material Densification: Ensure the system includes high-strength graphite molds capable of withstanding the mechanical pressure required to transmit force to the powder.

Ultimately, the quality of your Silicon Nitride depends entirely on the furnace's ability to maintain thermal absolute consistency during the reaction phase.

Summary Table:

| Feature | Role in Nitridation Process | Impact on Quality |

|---|---|---|

| 1400°C Environment | Activates gas-solid reaction kinetics | Ensures chemical synthesis of Si3N4 |

| Graphite Elements | High thermal conductivity & uniform radiation | Eliminates temperature gradients |

| Nitrogen Atmosphere | Serves as the reactive gas source | Facilitates deep core nitridation |

| High-Strength Molds | Transmits mechanical pressure to powder | Promotes material densification |

| Atmosphere Control | Prevents oxygen infiltration | Protects graphite and purity |

Elevate Your Advanced Ceramic Production with KINTEK

Precision nitridation requires absolute thermal consistency and specialized atmosphere control. KINTEK provides industry-leading graphite resistance furnaces, CVD systems, and vacuum solutions designed specifically for high-performance materials like Silicon Nitride.

Why Choose KINTEK?

- Expert R&D: Our systems are engineered to eliminate temperature gradients for structural homogeneity.

- Customizable Systems: Tailored Muffle, Tube, and Rotary furnaces to meet your unique lab or industrial requirements.

- High-Pressure Reliability: Specialized graphite components that withstand the rigors of material densification.

Ready to achieve complete nitridation and superior material properties? Contact our technical experts today to discuss your customized furnace solution!

Visual Guide

References

- You Zhou, Manabu Fukushima. Effects of rare‐earth oxides on microstructure, thermal conductivity, and mechanical properties of silicon nitride. DOI: 10.1111/jace.70028

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the requirements for the sealed furnace shell in a vacuum furnace? Ensure Perfect Sealing and Durability

- What materials are used in vacuum brazing? Join Reactive & Dissimilar Metals for High-Integrity Assemblies

- What are the advantages of using a Vacuum Spark Plasma Sintering (SPS) system over traditional furnaces for TiB2-SiC?

- What are the categories of vacuum sintering furnaces based on vacuum degree? Choose the Right System for Your Materials

- How does the sintering process work? Master the Art of Powder-to-Solid Transformation

- What types of heating elements are used in vacuum furnaces and what are their temperature capabilities? Optimize Your High-Temp Processes

- What are the benefits of using vacuum furnaces for heat treating compared to traditional methods? Achieve Superior Quality and Control

- What are the main advantages of multiple-chamber vacuum furnaces? Boost Efficiency and Throughput in Heat Treatment